Detailed description

2.1 NC/PLC interface signals

Basic logic functions: Various NC/PLC interface signals and functions (A2)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

15

Function: Hold

The hold function does not correct the setpoint position of the machine axis to the actual

position. If the machine axis moves away from the setpoint position, a following error

(difference between setpoint and actual position) is generated. This error is corrected

"suddenly" when the servo enable is set by the position controller, without observing the

axial acceleration characteristic.

The following interface signals have to be set for the hold function:

DB31, ... DBX2.1 = 0 (servo enable)

DB31, ... DBX1.4 == 0 (follow-up mode)

Feedback:

DB31, ... DBX61.3 = 0 (follow-up mode active)

During "hold", clamping or zero-speed monitoring are active.

Notice

With the "hold" function, once the servo enable has been set, the setpoint/actual-value

difference is corrected: directly by the position controller, i.e., without following the axial

acceleration characteristic.

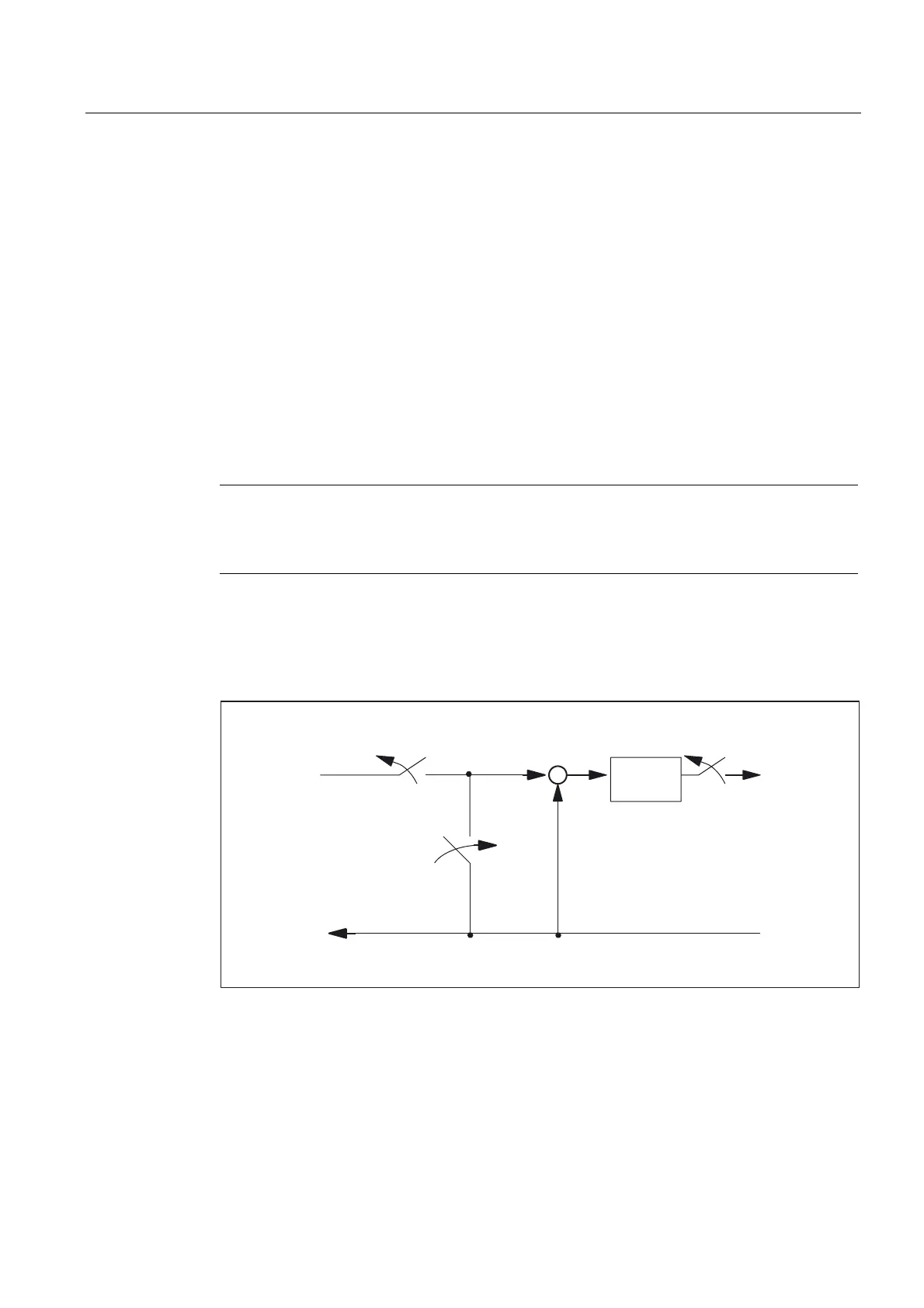

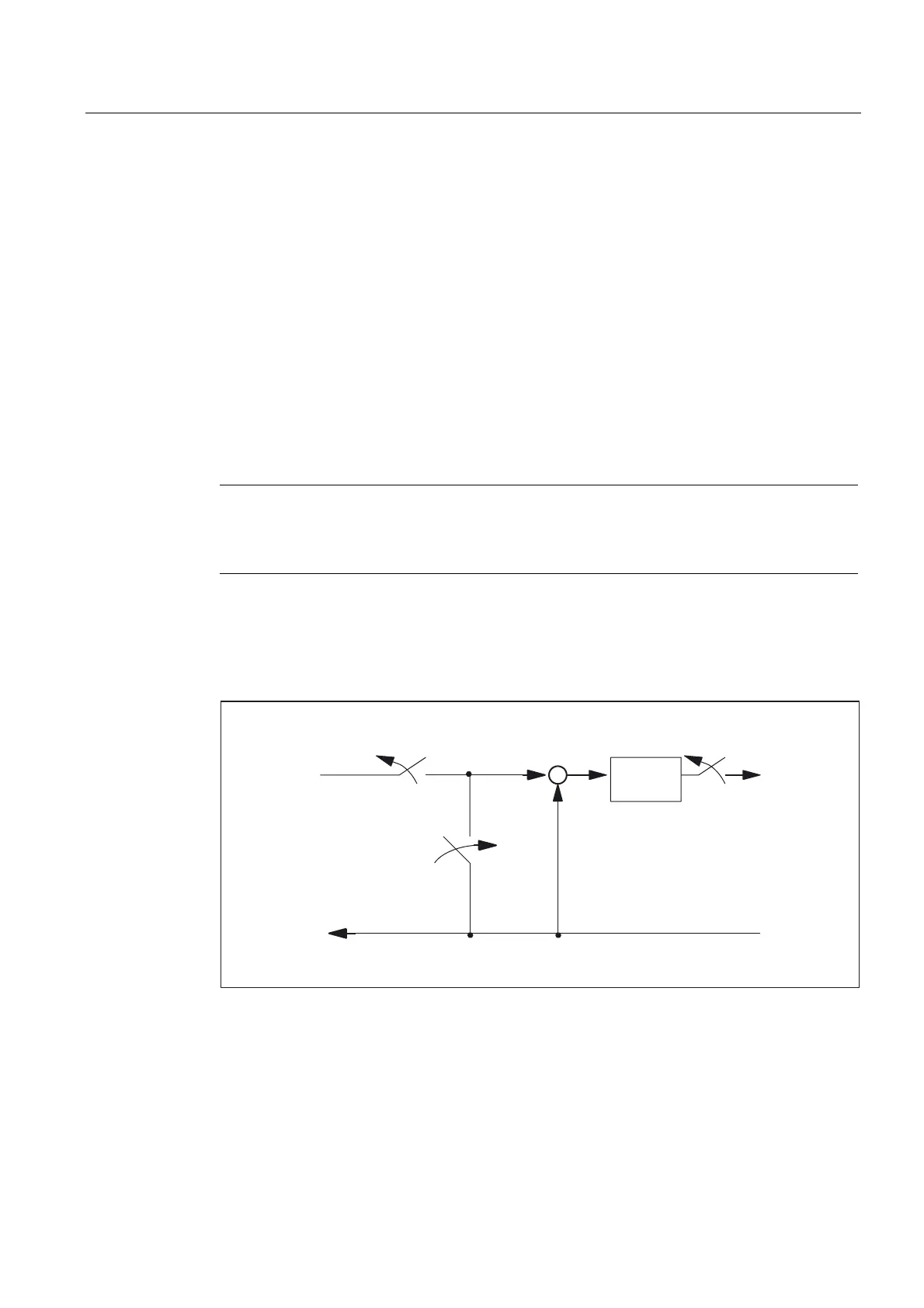

Application example

Positioning response of machine axis Y following clamping when "servo enable" set.

Clamping pushed the machine axis from the actual position Y

1

to the clamping position Y

k

.

B

3RVLWLRQ

FRQWUROOHU

3RVLWLRQVHWSRLQW

IURP,32

6HWSRLQW

IROORZXS

&RQWUROOHUHQDEOH

FDQFHOHG

3RVLWLRQ

DFWXDOYDOXH

Figure 2-1 Effect of servo enable and follow-up mode

Loading...

Loading...