Detailed description

2.2 Zeros and reference points

Basic logic functions: Axes, coordinate systems, frames (K2)

36 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Reference point R

The position of the reference point R is defined by cam switches. Reference point R

calibrates the position measuring system.

With incremental encoders, the reference point must be approached every time the control

power is switched on. The control can only then work with the measuring system and

transfer all position values to the coordinate systems.

Toolholder reference point T

The toolholder reference point T is located on the toolholder locator. By entering the tool

lengths, the control calculates the distance between the tool tip (TCP Tool Center Position)

and the toolholder reference point.

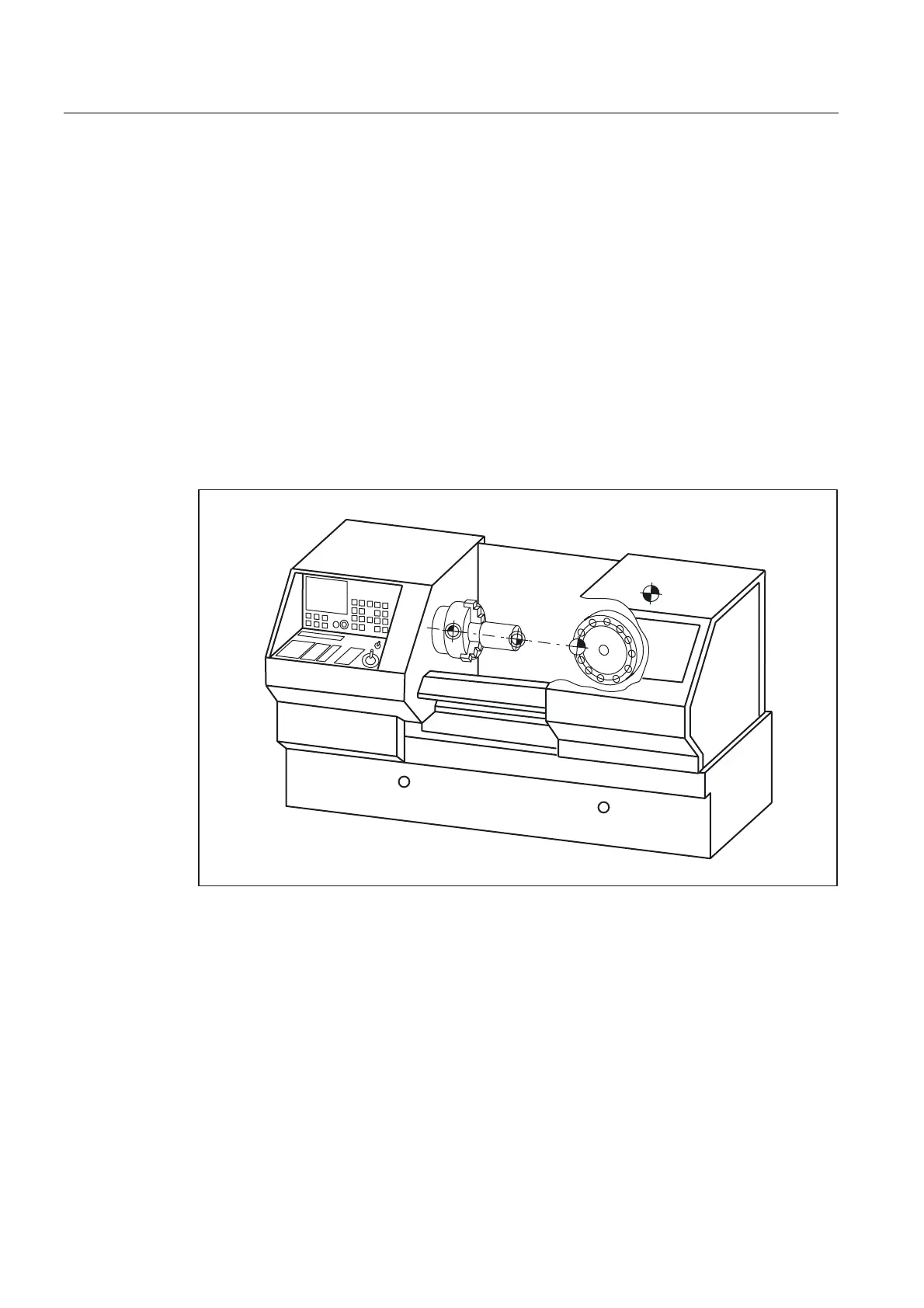

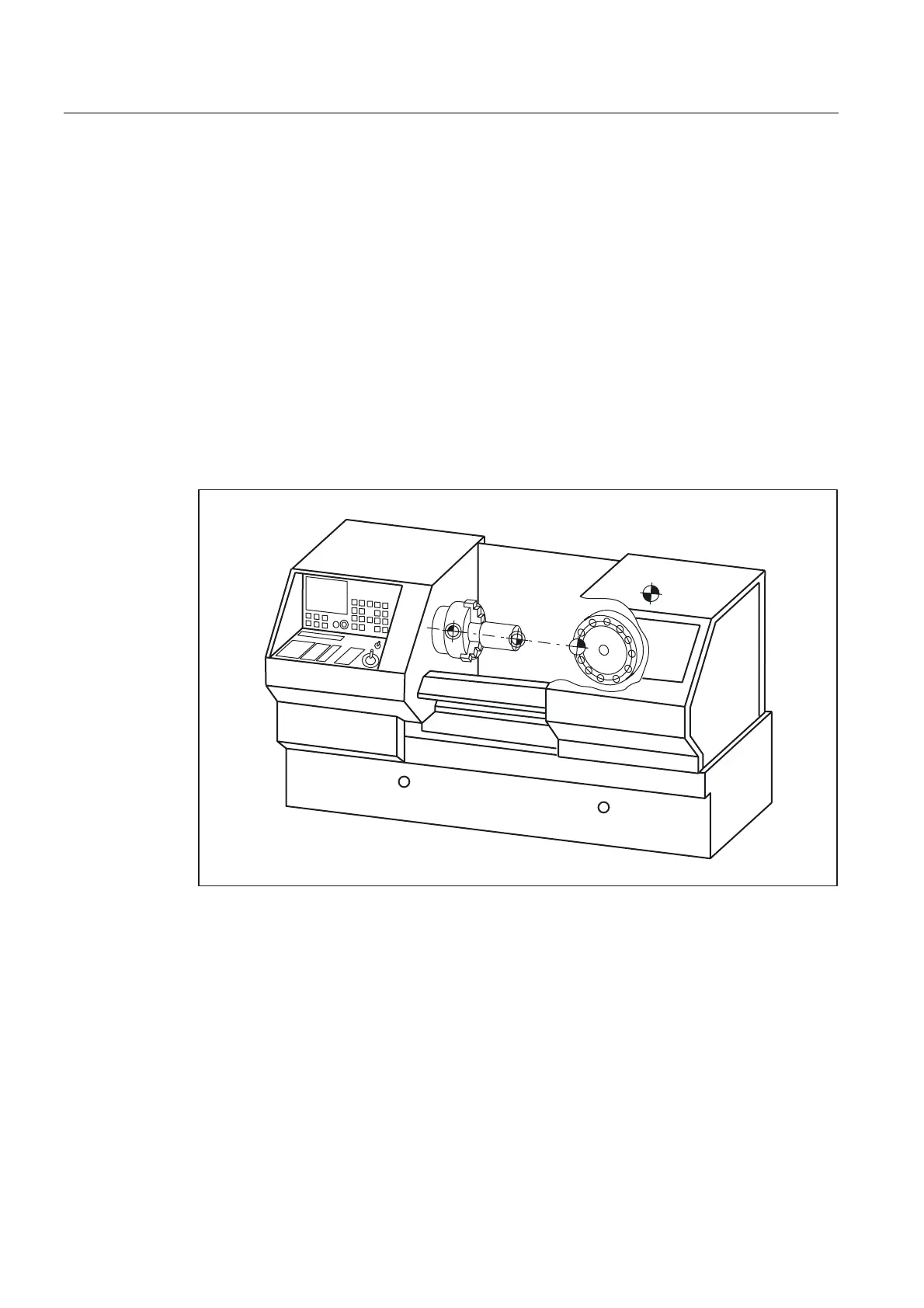

Example: Zeros and reference points on a turning machine

:

7

0

5

Loading...

Loading...