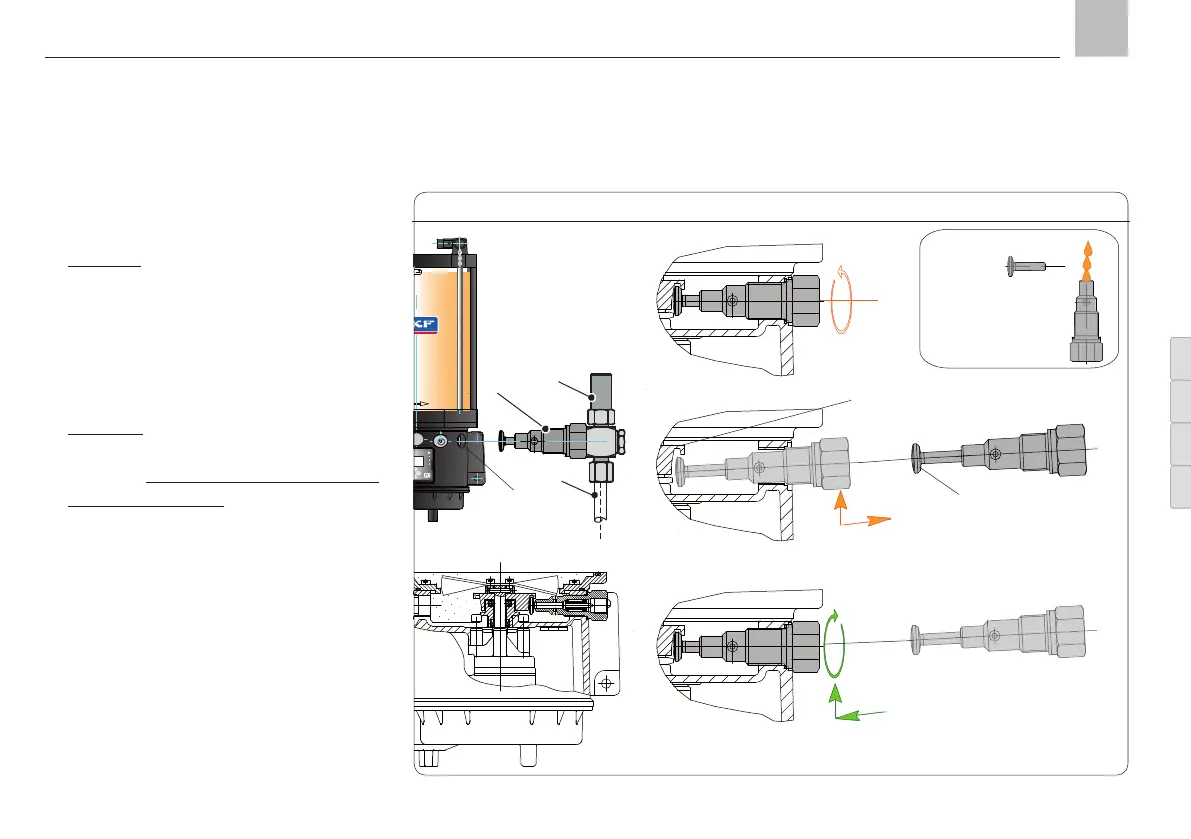

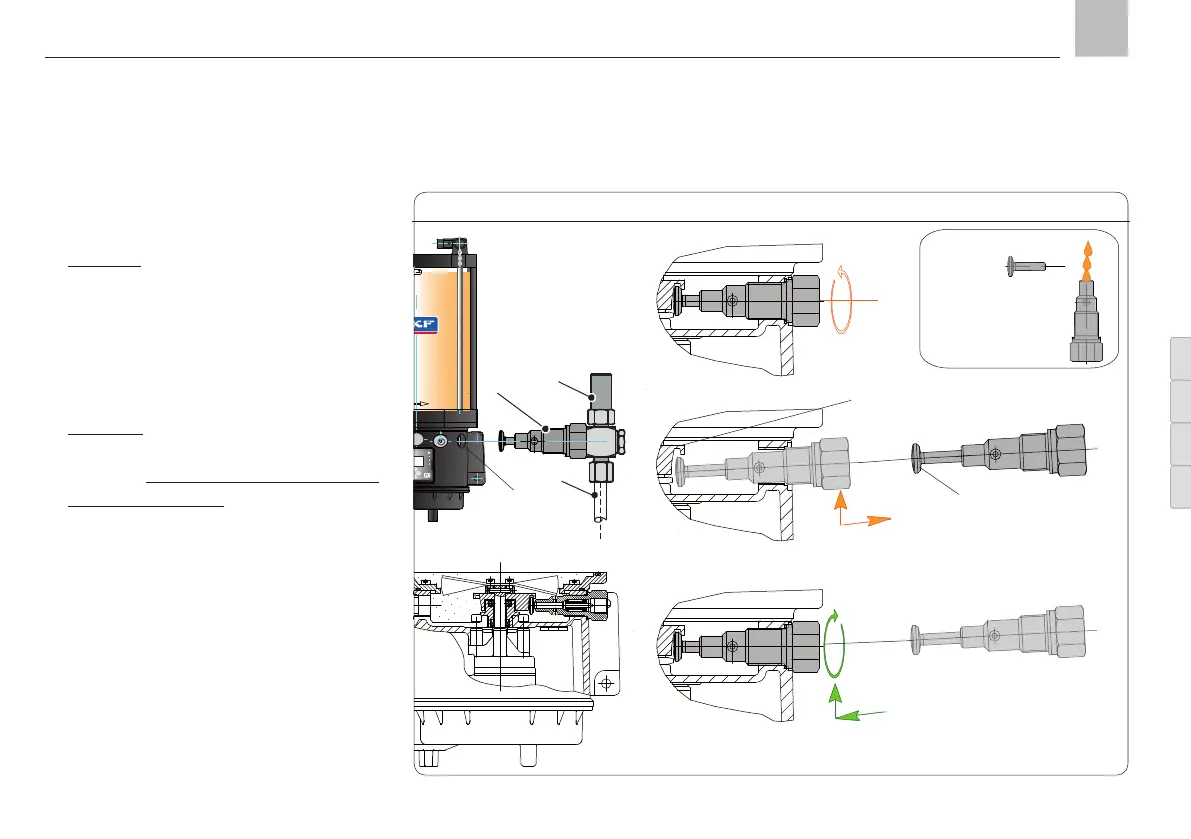

Assembly, positively driven pump element, Fig. 9

1

2

3

1

2

3

Section A

Section B

Section D

Section C

the housing bore with a bar magnet (or

taper-nose pliers).

• Section C Carefully pull the piston (6) out of

the new pump element (1)

• Coat the bore of the pump element lightly

with grease

• Insert the piston in the bore of the pump

element, leaving as much of the piston as

possible protruding from the bore

• Section D Slowly insert the pump element (1)

at an angle into the housing bore (5) until

the piston bottoms out under the guide of

the eccentric ring (4)

• Straighten the pump element (1) horizon-

tally and screw it into the housing bore (5)

by hand

• Tighten pump element (1) at a torque

of 35 Nm.

• Switch on pump and leave running until

grease without bubbles discharges from the

pump element outlet.

•

Connect pressure regulating valve (2) (or

lubrication line (3) to the pump element (1 )

and tighten at a torque of 25 Nm

6

4

5

Insert pump element (1) into

housing hole (5) and twist in

by hand!

KFG KFGS KFGL KFGCKFG KFGS KFGL KFGC

Page 25

EN

Assembly instructions

Loading...

Loading...