3V2V1

1

1

1

1

1

1

2

2

2

2

2

2

3

3

3

3

3

3

4

4

4

4

4

4

1

2

3

4

1

2

2

1

2

1

2

1

1

2

3

4

1

2

3

4

1

2

3

4

A B C

1 2

3

4

5 6

7

X1

BN

RD-BK

BU

PK

BK

BK

VT-GN

CAN-BUS

M12x1

1x21M1x21M

M12x1

1x21M1x21M

M12x1

1x21M1x21M

M12x1

F1

S1

M L

31 30

15

CS4 (MC)

V4

SL2

RD

CS1

CS1

CS2

CS2

CS3

CS3

V1 V2 V3

+++++++ + +

–– – – –

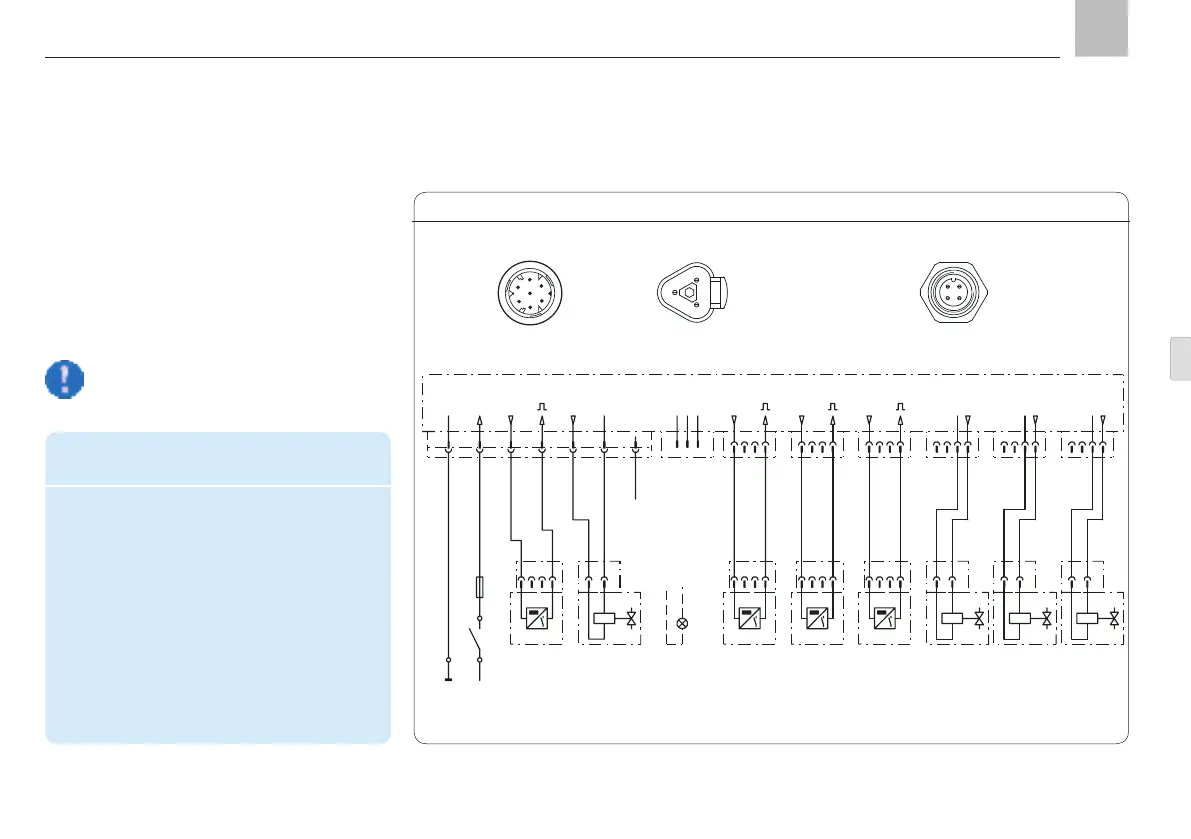

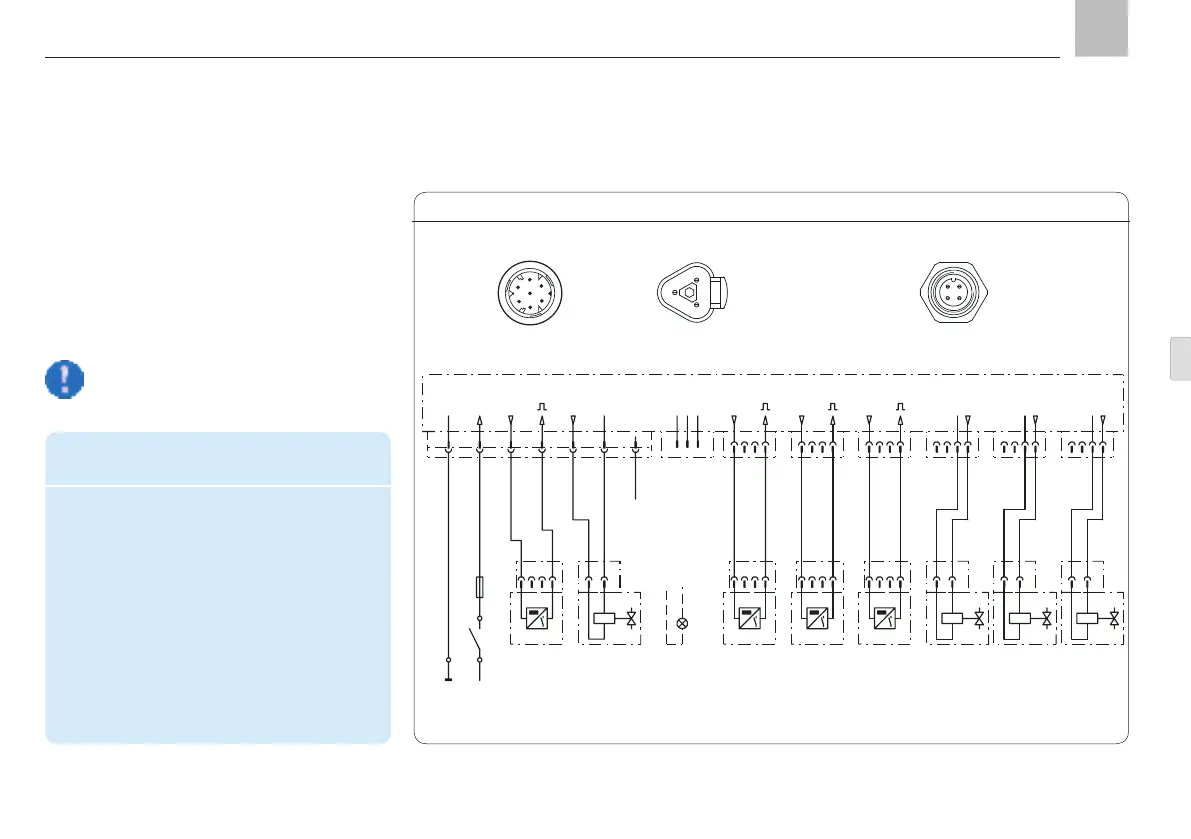

4.9.2 Connectivity

Example of the connection of four reversing

valves and four piston detectors for units with

maximum configuration (6x circular connectors

M12x1 available) for the operation of a pro-

gressive feeder system, divided into four lubri-

cation segments

A

B

C

CS.. = piston detector V.. = reversing valves

2

4

5

3

1

6

7

34

1 2

Assignment of the 7-pin

circular connector

Assignment of the 4-pin circular

connector M12x1

possible.

Legend for maximum configuration connection

example

CS1 – CS4 Piston detector 1 – 4

V1 - V4 Valves 1-4

MC Machine contact

SL2 "Fault" indicator light

(can be operated as an

alternative in place of valve 4)

L+ + Supply voltage potential

S1 Ignition switch

F1 Fuse

Assignment of the

CAN bus connector

KFGC

Maximum configuration example, Fig. 28

Page 39

EN

Assembly instructions

Loading...

Loading...