9.4.4 With system monitoring

In this operating mode, system functions are

additionally monitored using external switches.

The following can be monitored:

Fill level in the lubricant reservoir

Function of progressive feeder using a

piston detector

9. KFGS control unit

9.4.3 No system monitoring

In this operating mode, the lubrication cycle

is controlled solely by the pre-set values for

PAUSE and CONTACT.

Monitoring must be switched off.

COP = OFF System malfunctions are

not automatically detected or displayed.

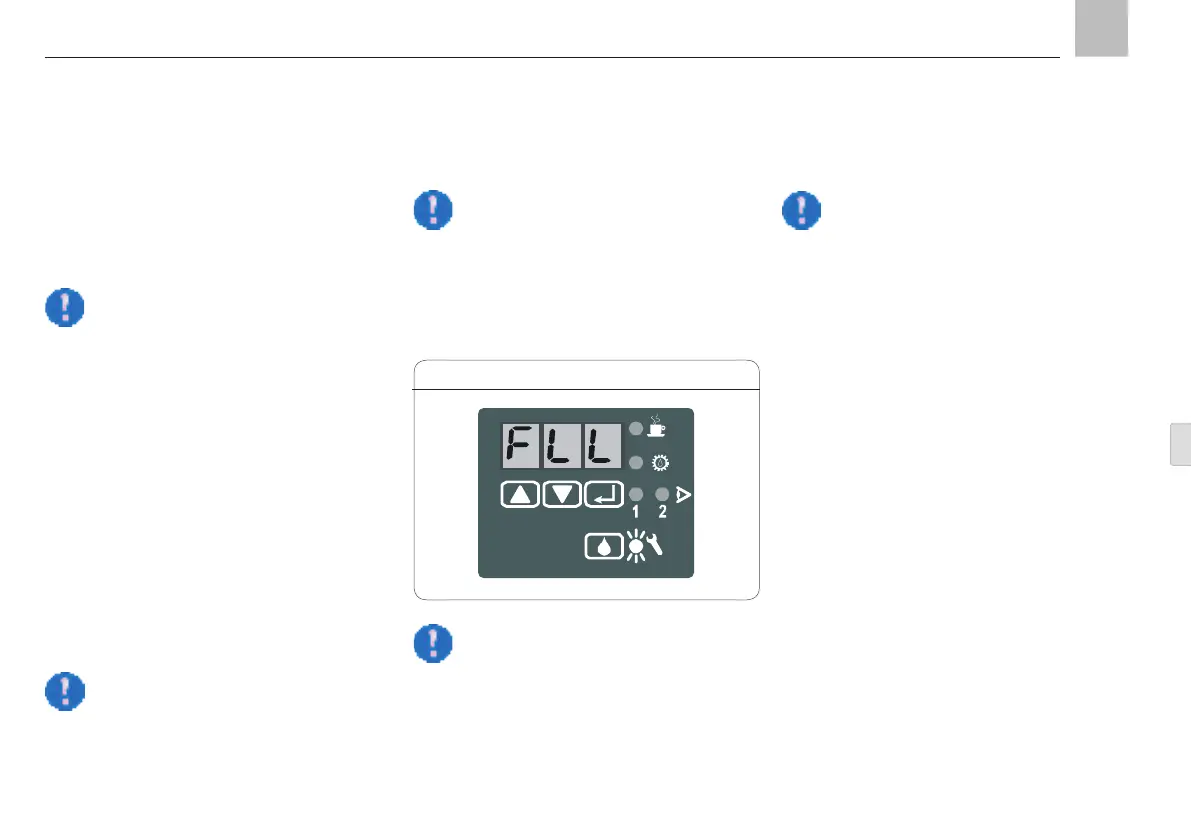

9.5 Fill level monitoring

always active.

If the level in the lubricant reservoir falls below

the minimum fill level, the lubricant cycle is

stopped and a fault notification is issued on the

display.

requires that it be sent to the factory for

rework.

Display mode, Fig. 16

9.5.1 Monitoring via piston detector

Only possible for centralized lubrication

systems with progressive feeders.

For greases up to NLGI Grade 2.

The piston detector monitors the movement of

pistons in the progressive feeder during

CONTACT time (pump cycle time). The follow-

ing monitoring setting must be activated in

programming mode:

COP = CS (see Chapter 9.3.3).

KFGS

Operational malfunctions are automat-

ically detected and displayed. Monitor-

ing is switched on.

COP = CS or COP = PS

Page 79

EN

Loading...

Loading...