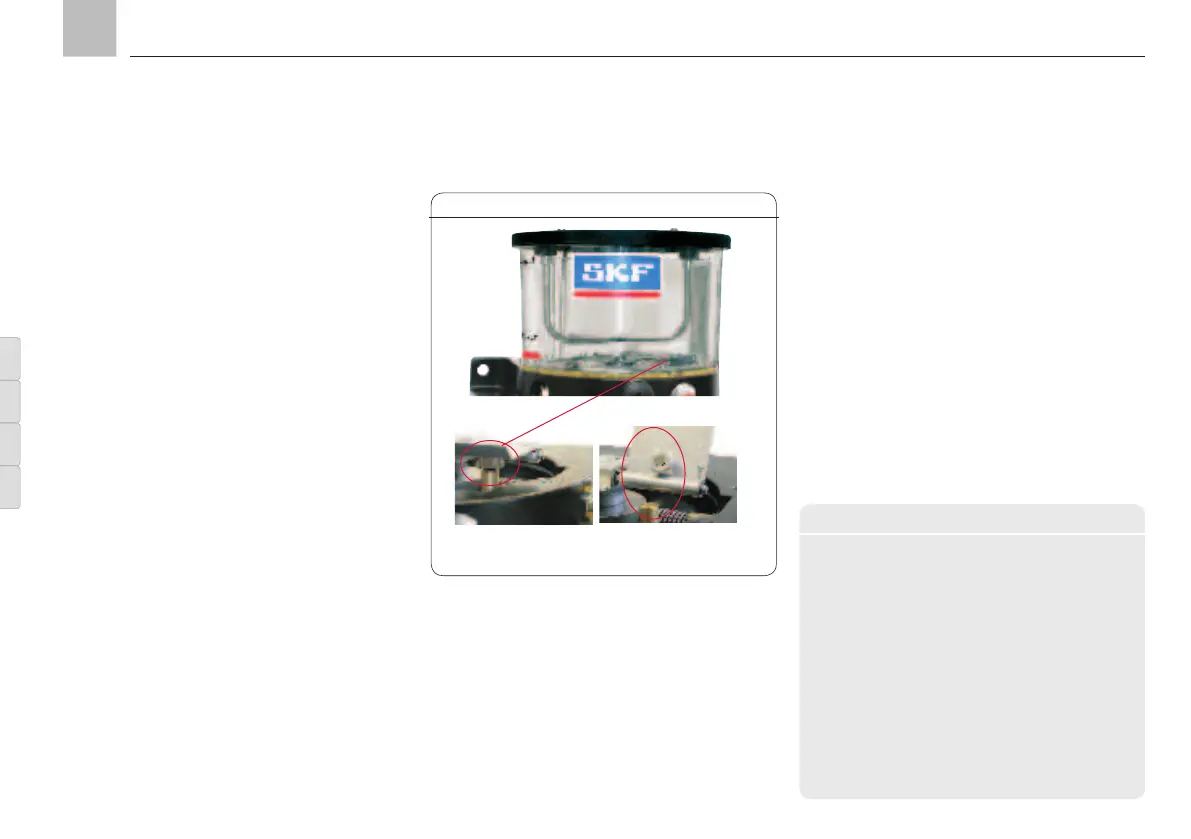

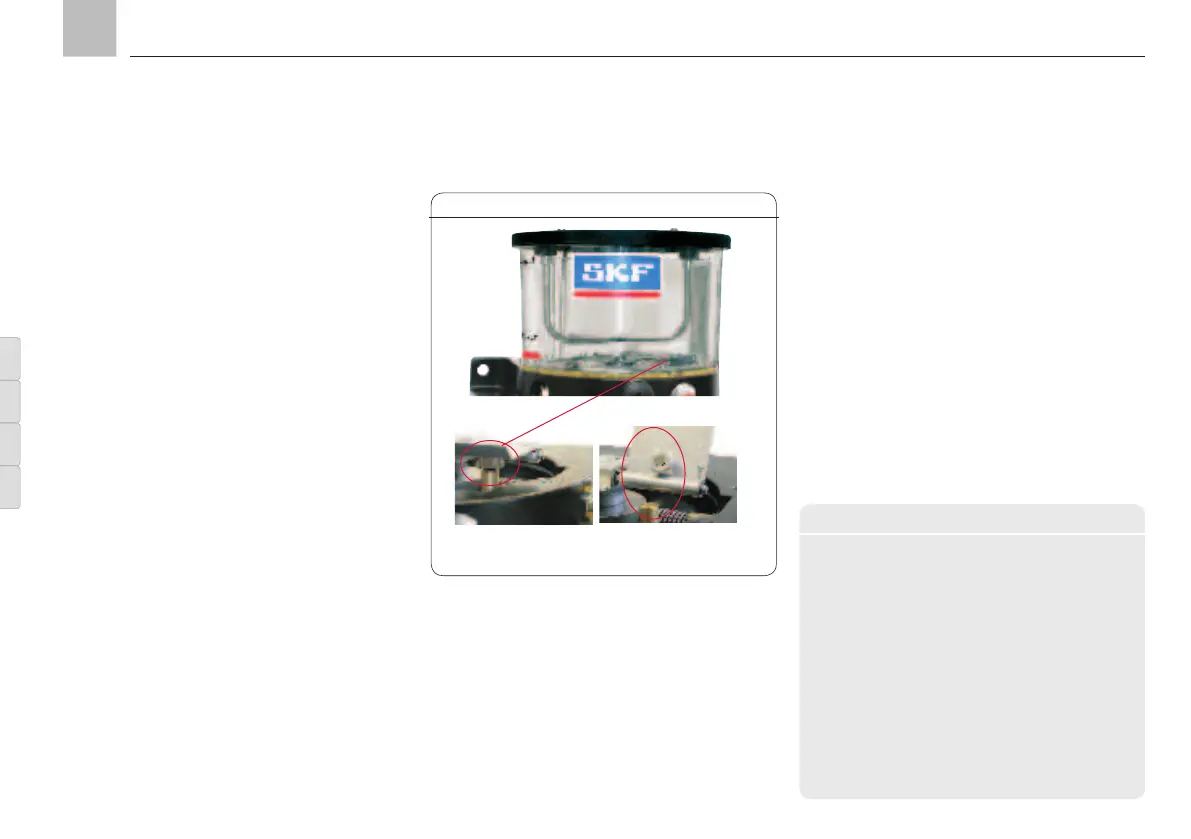

Fill level monitoring W1, Fig. 30

4.11 Fill level monitoring

Two different fill level switches can be fitted as

standard on the KFGS and KFGL pump units for

the purpose of indicating the “Minimum” lubri

-

cant fill level

Order code 1 (formerly W1 control) for

greases of NLGI ≥ 2

Order code 2 (formerly W1G control) with

signal smoothing, for greases of NLGI ≥ 2

With pump design KFG (without control unit)

with fill level monitoring the monitoring signals

are processed by a system provided by the

customer;

in the KFGS and KFGL versions the monitoring

switch is connected to the pump's control sys-

tem. This effectively prevents the fill level from

falling below the minimum, thus preventing any

damage to the KFG pump units which could

result from that.

On KFGC pump units, fill level control is cus-

tomized according to customer specifications.

4.11.1 Order code 1 (W1)

max. 24 VDC, for greases of NLGI Grade ≥ 2

Technical data

Fill level monitoring

Function ............. Mechanical, by dry

reed contact

Contact form .......... NO-contact

Switching capacity, max. .. 0.6 W

Switching voltage, max.... 24 VDC

Switched current, max. ... 25 mA;

resistive load only

1

)

Plug-in connection DIN EN 60947/IEC 947

2

)

Wiring diagram Circular connector M12x1

1) No inductive load, no lamp load (indicator lamp)

2) Cable socket - see Accessories Chapter 16

Functional description

The fill level switch W1 is designed as a rocker

switch integrated in the base of the reservoir. A

magnetic rocker mounted on the agitator is

pushed down by resistance from the grease

when the reservoir is full. A pulse is generated

with every revolution of the agitator. When the

minimum fill level is reached, the resistance

from the grease on the rocker gives way. The

rocker then snaps back up and the pulse is

interrupted.

KFG KFGS KFGL KFGC

Contact W1 open,

fault position

Contact W1 closed,

go position

Page 42

EN

Assembly instructions

Loading...

Loading...