31 15

1

BN

KFGS...

F

2 3 4 5 6 7

X1

RD-BK

BU

PK

DK

SL2

2,4 W

Programming:

- Chapter 9 of assembly instructions

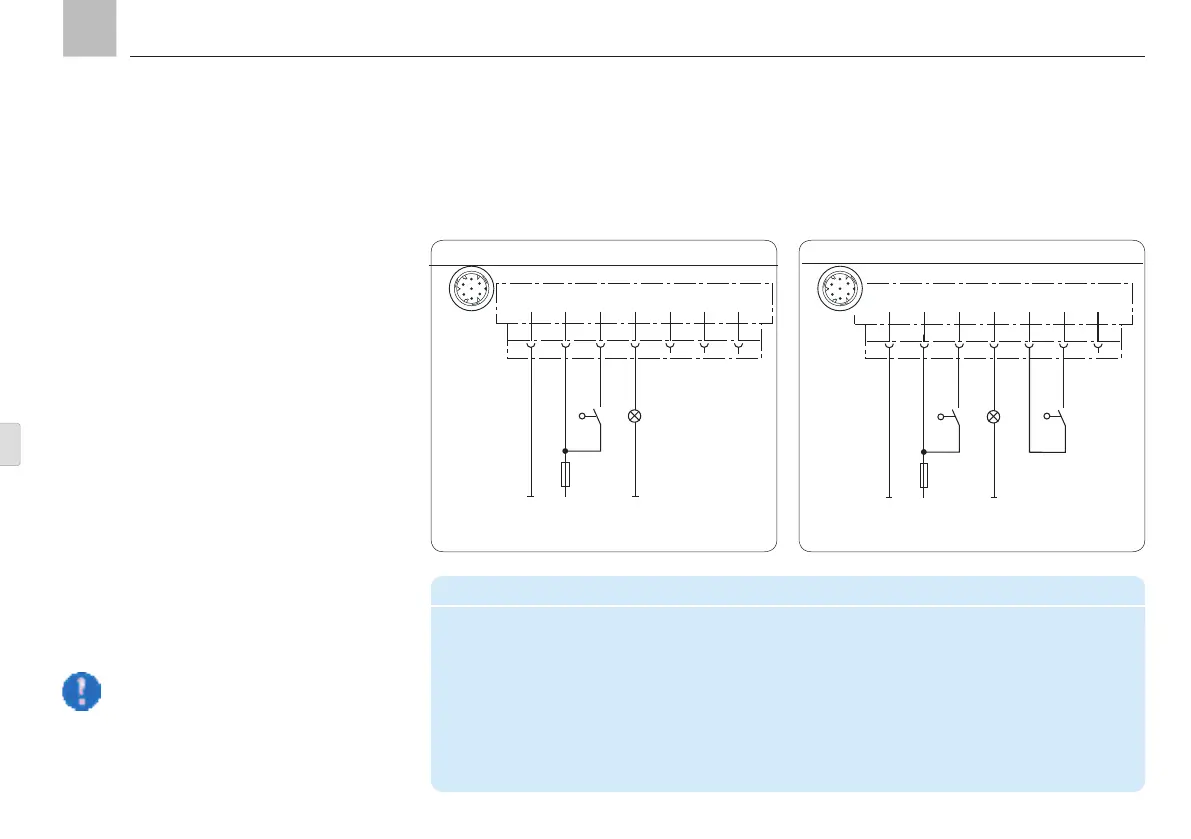

4.7.2 Connectivity

Counter operation without system monitoring

Connector pin assignment in counter operation

PIN Code Assignment

1 31 - Supply voltage potential (0V, GND)

2 15 + Supply voltage potential ("ignition ON")

4 SL2 "Fault" indicator light

5 ZS Piston detector „+“

6 ZS Piston detector "Signal"

7 SL1 "Pump ON" indicator light

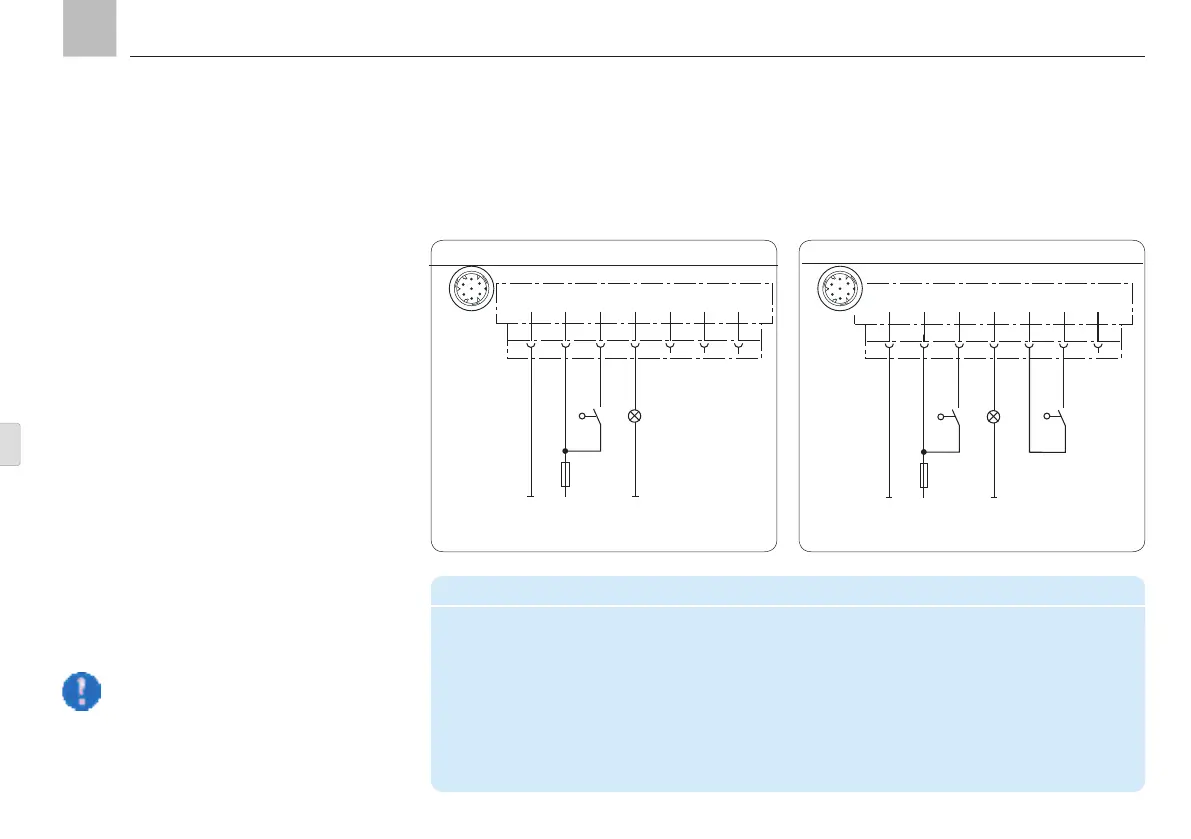

4.7.3 Connectivity

Counter operation with system monitoring

31 15

1

BN

KFGS...

F

2 3 4 5 6 7

X1

RD-BK

BU

PK

DK

SL2

2,4 W

BK

BK

ZS

Programming: cPA, tCO, COP = CS

One pulse is counted each time the

operating voltage is switched on when

the pushbutton is closed in counter

operation.

Control using machine pulses

(Counter mode = load-dependent lubrication)

The duration of the interval time is determined

by a pulse generator that sends pulses to the

control unit based on how long the machine

has been running. The control unit counts the

pulses that are received and starts the pump

after the pre-set number of pulses.

The pump cycle time is defined by a time val-

ue. Both the number of pulses that determine

the interval time and the pump cycle time can

be configured.

The fill level monitoring unit is internally con-

nected to the integrated pump control unit. A

fault notification can be sent to the process

control level via indicator light SL2.

Assembly instructions

Programming: cPA, tCO, COP = OFF

2

4

5

3

1

6

7

2

4

5

3

1

6

7

KFGS

KFGS connection, Fig. 18

KFGS connection, Fig. 19

Page 32

EN

Loading...

Loading...