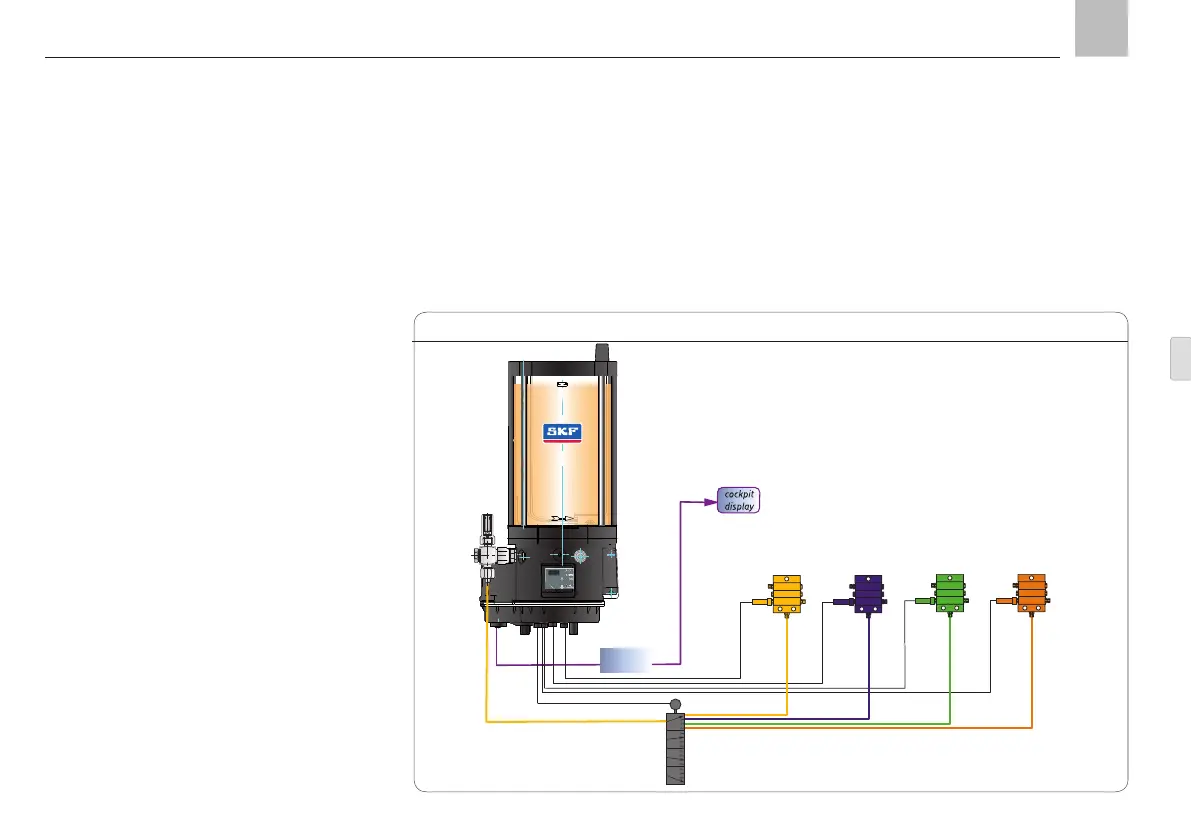

6.3 Progressive systems with

KFGC (CAN bus) pump unit

The general functional description for progres-

sive systems with a KFGS pump unit also

applies for the design with CAN bus pump

control.

The integrated LC-CAN 5000 control unit per-

mits the lubrication zone of a progressive feeder

system to be distributed into individual lubrica-

tion segments which can be configured with

individual parameters (e.g., contact and interval

times). Up to four lubrication segments can be

installed in total.

To distribute the lubricant, a corresponding

number of electric switch valves is installed in

the lubrication line leading from the pump ele-

ment. A valve is opened as soon as the control

unit starts a pump cycle for the corresponding

lubrication segment.

The pump can only provide adequate lubrica-

tion to one lubrication segment at a time, so it

must be ensured that only one valve is opened

during operation. This is handled by the control

unit in automatic and semiautomatic

operation.

When CAN commands are used for control,

valve opening must be ensured by selecting

the appropriate contact and interval times or

by using appropriately programmed processes

in the external lubrication program to switch

6. Functional description in progressive systems

Example of progressive system with KFGC pump unit (CAN bus), Fig. 5

central machine control

CAB Bus

SAE J1939

max

the valves in a carefully coordinated sequence

so that only one valve is opened at a time.

KFGC

Page 59

EN

Loading...

Loading...