115

MAINTENANCE

A careful maintenance of the planter ensures proper functioning and long service life of the

machine.

BEFORE PERFORMING THESE OPERATIONS, THE PLANTER’S ENGINE MUST BE TURNED OFF AND

THE IGNITION KEY REMOVED.

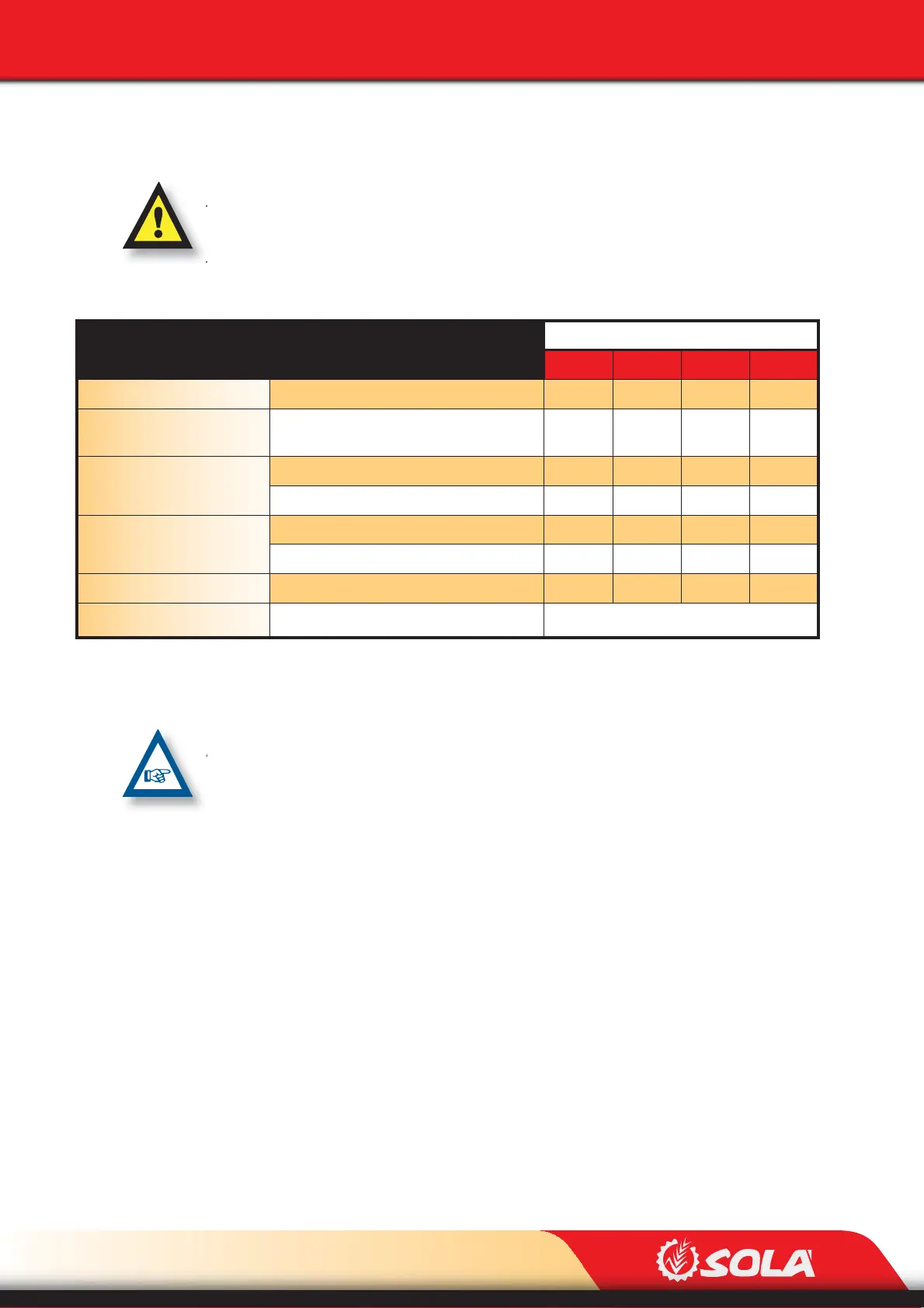

The next table shows the maintenance operations to be performed on the machine along with

their (GUIDANCE) frequency:

AFTER THE FIRST 10 HOURS OF WORK, TIGHTEN THE SCREWS THAT SECURE THE METERING

UNITS, THE THREE POINT LINKAGE, THE WHEELS AND THE TRACK MARKERS’ SUPPORTS.

PLANTER’S PART TASK TO BE PERFORMED

NUMBER OF HOURS

20 50 100 500

Machine’s components Greasing of all the components

ƔƔ

Fan

Adjusting the belt’s tension (in versions equipped with

mechanical fan)

Ɣ

Drive wheels

Check of the tyre pressure

Ɣ

Replace the transmission’s fusible pin

Ɣ

Chain transmissions

Lubrication of the transmission chains

Ɣ

Adjusting the transmission chains’ tension

Ɣ

Metering box Lubrication of the transmission chains

Ɣ

Gearbox Oil change

Every 5 years

Loading...

Loading...