74

Fig. 6.79

ADJUSTMENTS

The press wheels admit the following adjustments (Fig.

6.79):

- Working WIDTH, depending on the planting

depth.

- PRESSURE exerted by the wheel onto the

terrain.

- BEARING ANGLE of both wheels, unless using

out-of-phase press wheels, since their bearing

angle can not be adjusted.

THE PRESS WHEELS NEED TO BE CLEANED PERIODICALLY.

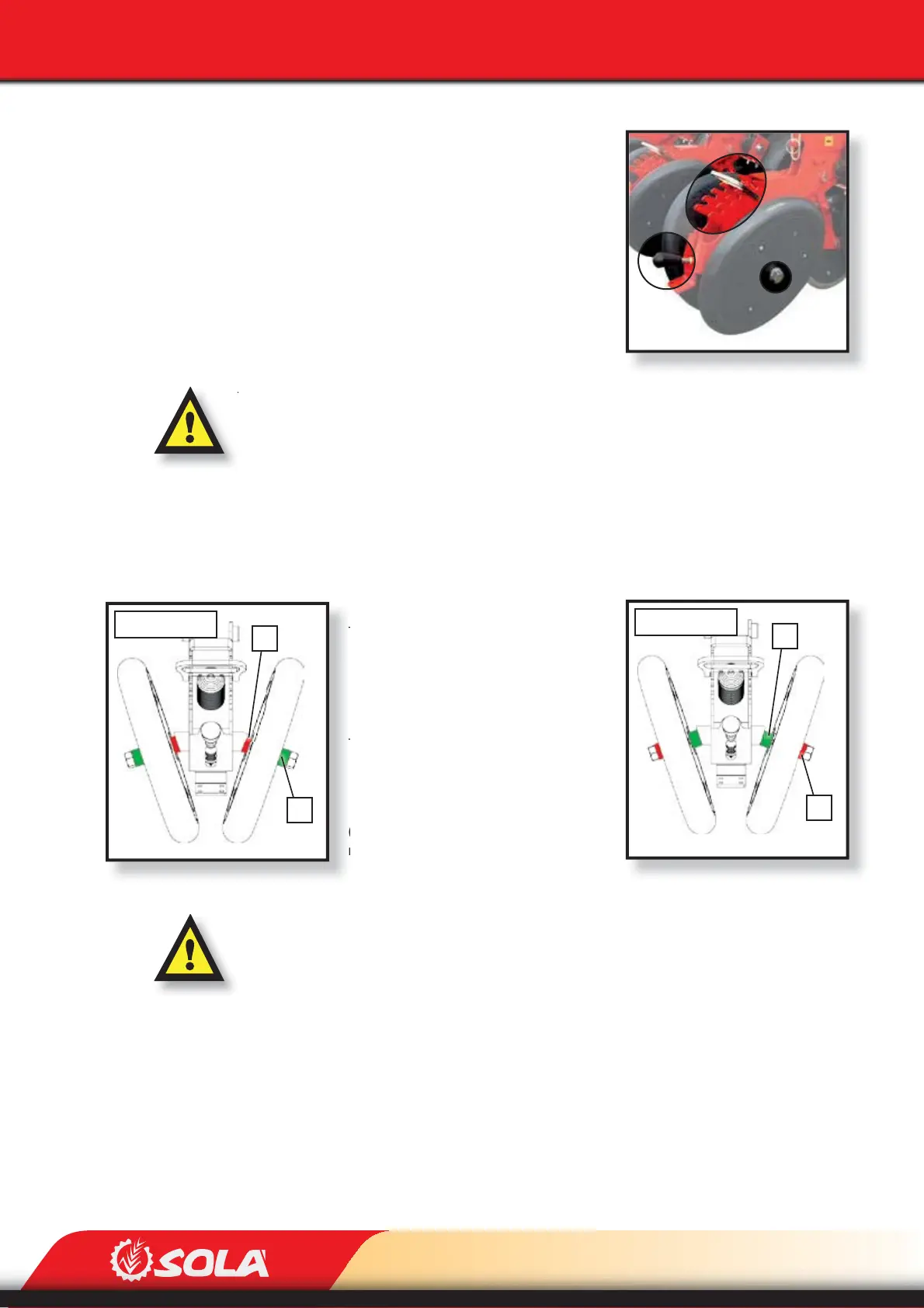

6.11.1.1 WHEEL’S WORKING WIDTH

Depending on the planting depth, the working width of the press wheels needs to be adjusted

so that they cover and compact the seed properly:

- PLANTING DEPTH LESS THAN 2 CM

or when THE FURROW STAYS OPEN:

the shaft sleeves A (narrow) and B

(wide) need to be assembled as shown

in picture 6.80.

- PLANTING DEPTH MORE THAN 2

CM: the shaft sleeves A (narrow) and B

(wide) need to be assembled as shown

in picture 6.81.

(*) This adjustment is valid for standard

rubber press wheels of 1’’ and 2’’.

IMPORTANT: BE SPECIALLY CAREFUL WHEN DISASSEMBLING THE WHEELS, SINCE THE THREAD

HAS A DIFFERENT DIRECTION DEPENDING ON THE SIDE TO PREVENT THE SCREW FROM LOOSE-

NING DURING WORK.

Fig. 6.80

A

B

Depth < 2 cm

Fig. 6.81

B

A

Depth < 2 cm

Loading...

Loading...