116

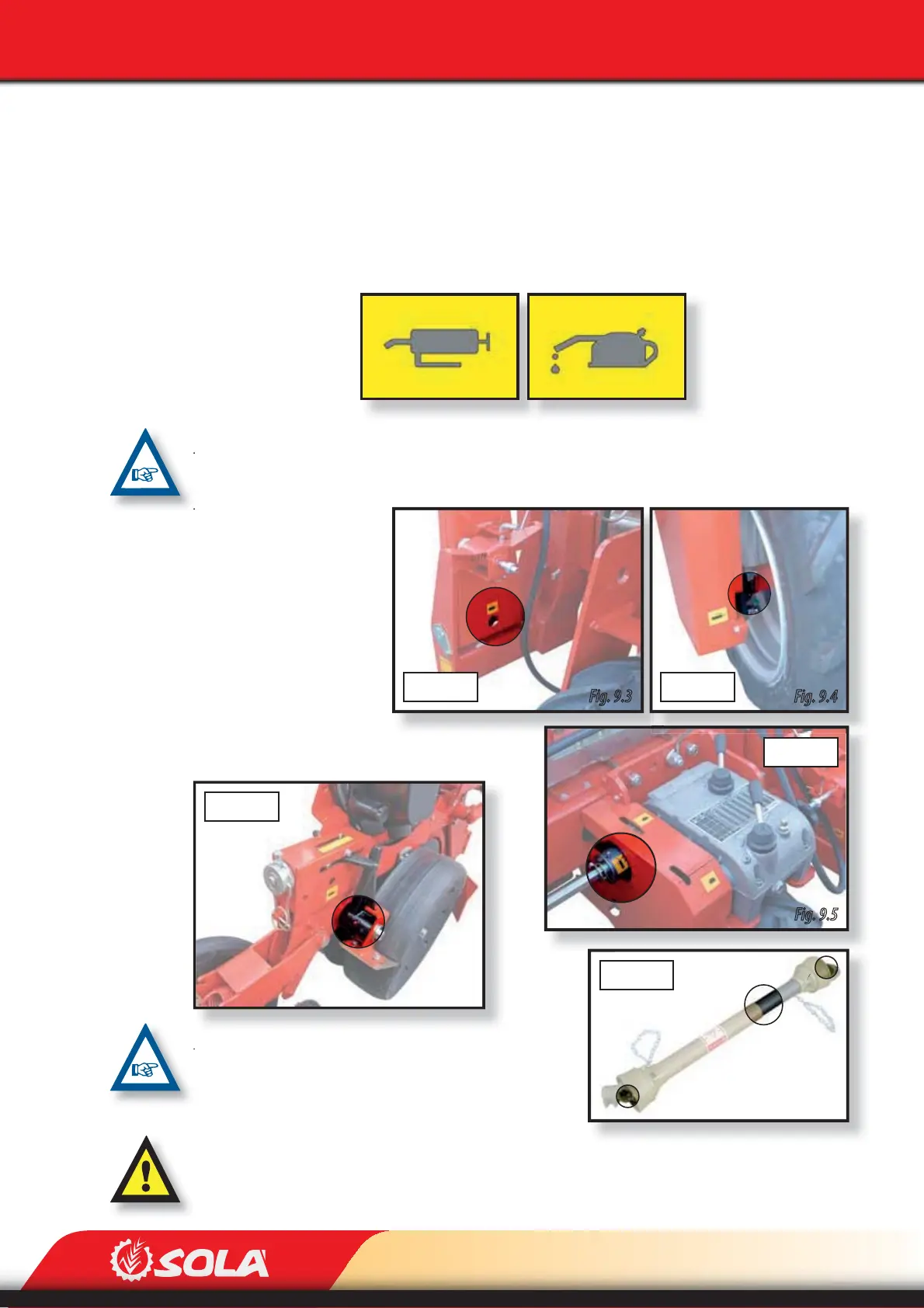

Fig. 9.1

Fig. 9.2

MAINTENANCE

9.2 GREASING AND LUBRICATION

Every non-painted metallic component of the planter is exposed to atmospheric and weather condi-

tions, which may oxidize them. For this reason, it is important to grease and lubricate these compo-

nents.

Attached to specic parts of the planter, you will nd adhesives with symbols to indicate the parts to

be GREASED (Fig. 9.1) or the points to be LUBRICATED (Fig. 9.2).

BEFORE LUBRICATING OR GREASING, WASH THE PLANTER TO REMOVE EARTH RESIDUES ATTACHED TO

THE MACHINE (see section 9.6 MACHINE CLEANING).

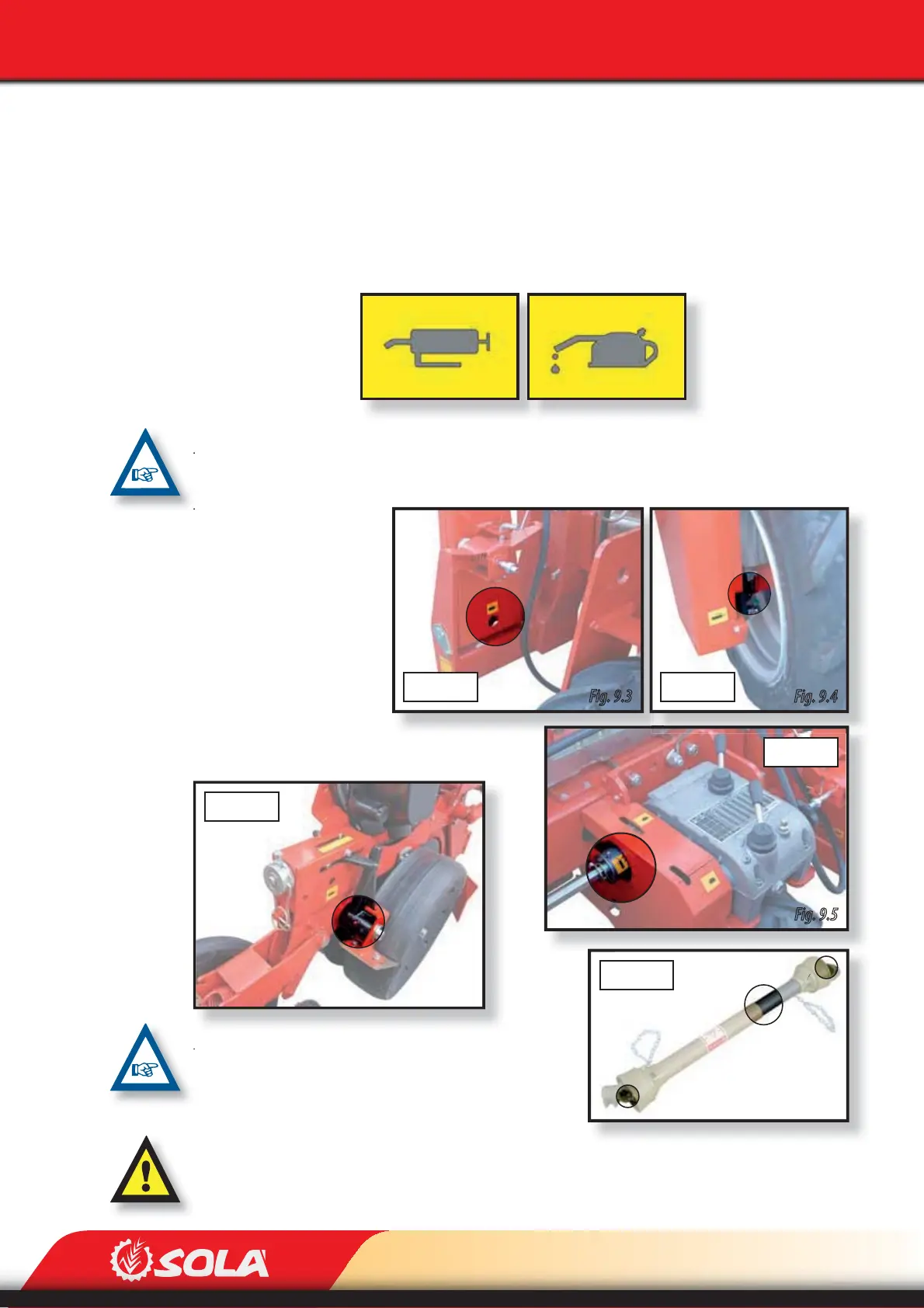

The following parts of the

planter should be greased:

- T

rack markers (Fig. 9.3)

- Driving wheels’ bus-

hings (Fig. 9.4).

- Each component of the

transmission (Fig. 9.5).

- Each component of the

metering units (Fig. 9.6).

- Each PTO shaft and

plastic axle of the PTOs

(Fig. 9.7).

TO GREASE THESE PARTS, ALWAYS USE SOLID CALCIUM

GREASE.

SOME PARTS OF THE MACHINE NEED TO BE GREASED EVERY 50 WORKING HOURS (SEE SECTION 9.1 CHEC-

KING FREQUENCY). NOT OBSERVING THESE GREASING RULES MAY RESULT IN DAMAGE TO THE PLANTER.

Fig. 9.3

20 hours

Fig. 9.6

20 hours

Fig. 9.5

20 hours

Fig. 9.4

50 hours

Fig. 9.7

50 hours

Loading...

Loading...