81

Fig. 6.99

A1A2A3A4

A5

B1B2

B3

Fig. 6.97

1

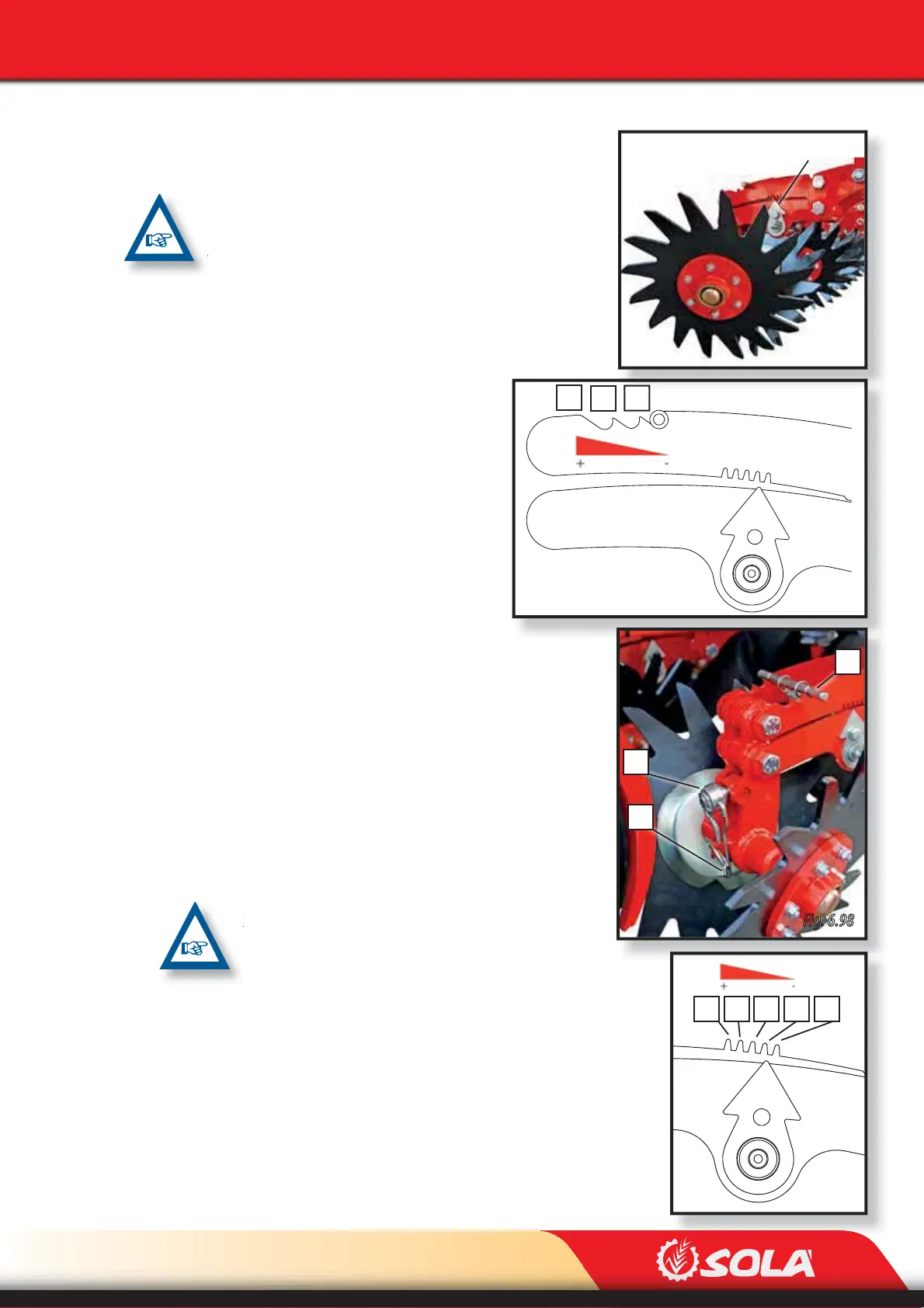

Fig. 6.98

2

3

ADJUSTMENTS

6.13 FURROW’S RESIDUE ROTARY CLEANERS WITH

PARALLELOGRAM (OPTIONAL)

PERFORM THIS OPERATION WITH THE MACHINE IN A RAISED

POSITION.

The furrow’s residue rotary cleaner pushes aside the residues

present in the sowing row. They need always to work super-

cially pushing the residue aside.

Both the PRESSURE exerted onto the ground and the WOR-

KING DEPTH STOP can be adjusted as follows:

PRESSURE

To adjust the pressure of the furrow’s residue

rotary cleaner, pull the handle (3, Fig. 6.98)

and place it at one of the 3 working positions

(B1, B2 or B3, Fig. 6.97).

WORKING DEPTH STOP

To adjust the working depth stop, follow

these steps:

1- Remove the pin (1, Fig. 6.98) to free the crank (2, Fig.

6.98).

2- Raise the furrow’s residue rotary cleaner using one

hand and use the other hand to turn the crank until

the working depth stop is set at the desired position.

For this purpose, use the depth indicator (3, Fig. 6.98).

3- Once the working depth stop has been set, lower the

crank (2, Fig. 6.98) and place the pin back (1, Fig. 6.98)

to lock the stop.

AFTER ADJUSTING, WORK THE GROUND SOME METRES

TO CHECK THAT THE WORKING DEPTH STOP HAS BEEN

CORRECTLY SET.

In the case of no-till farming on hard ground, it is not

necessary to adjust the working depth stop, since the

furrow’s residue rotary cleaners will adapt to the terrain

without turning the soil. In this case, the working depth

stop needs to be inactive, set at position A5 (Fig. 6.99).

In the case of tilled ground, either adjust the working

depth stop or exclude the furrow’s residue rotary clea-

ners. To exclude them, set the working depth stop at

position A1 (Fig. 6.99).

INDICATOR

Fig. 6.96

Loading...

Loading...