ADJUSTMENTS

9

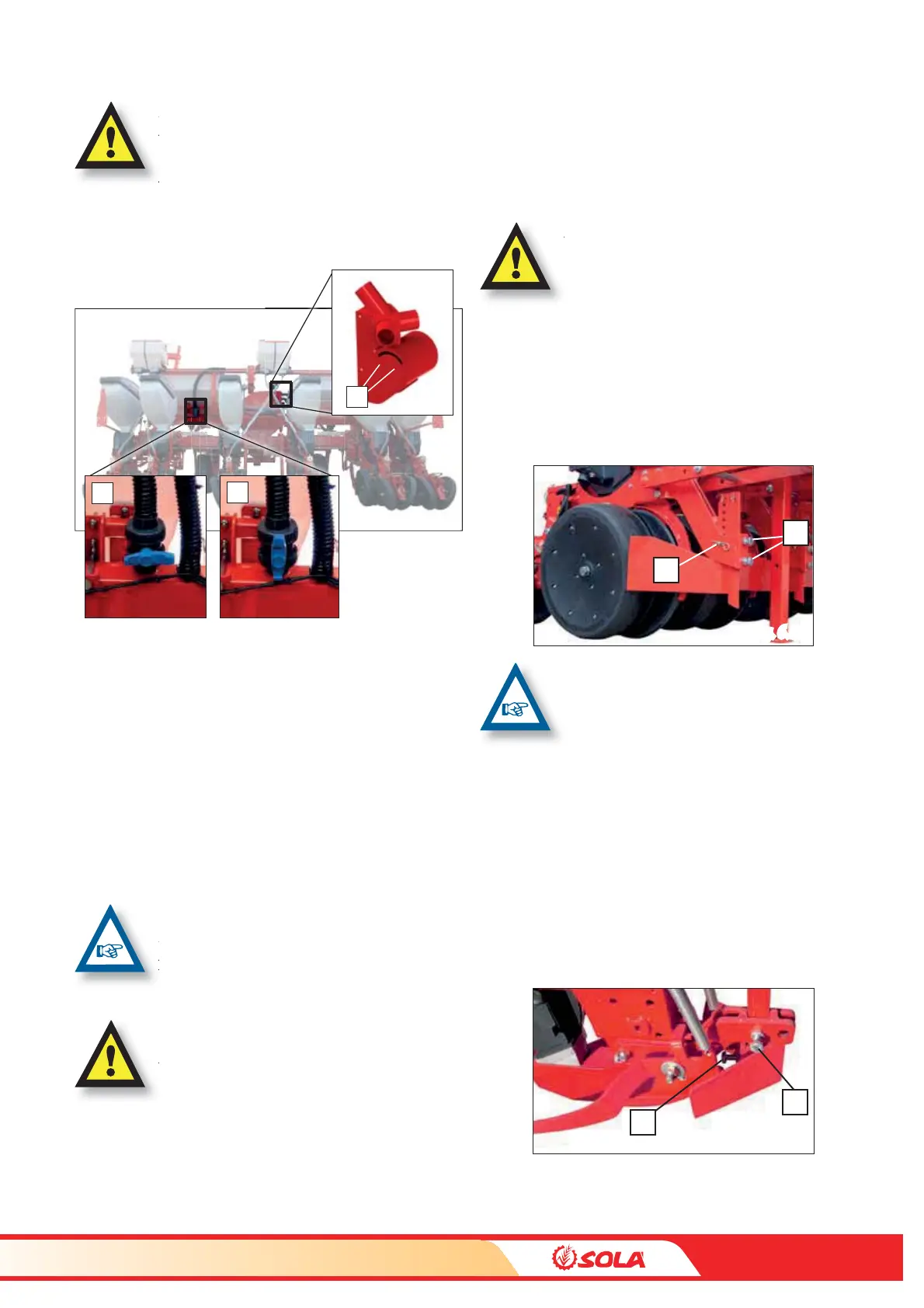

AFTER CHANGING THE POSITION OF THE AD-

JUSTING VALVE, CHECK THE PRESSURE VALUES

USING THE VACUUM GAUGE (FIG. 6.25). IF NE-

CESSARY, ADJUST THE FAN’S TURNING SPEED

TO ADAPT THE PRESSURE VALUES TO THE

ONES IN THE TABLE OF SECTION 6.4 SUCTION

SYSTEM-FAN.

Fig. 6.26

A1

A2

B

1

0

6.12 OPENING COMPONENTS

The depth at which the opening components are buried de-

pends on:

- The planting depth of the metering unit which has

the opening component assembled.

- The opening component’s adjustment.

ADJUST THESE COMPONENTS ONLY AFTER AD-

JUSTING THE METERING UNIT’S PLANTING DEP-

TH.

IN THE CASE OF NO-TILL FARMING, THE TUR-

BO DISC OPENERS NEED TO BE ASSEMBLED ON

THE PLANTER’S FRAME AND NEED TO COIN-

CIDE WITH EACH METERING UNIT’S SOWING

ROW. THE FURROW-OPENER BLADE NEEDS TO

BE ASSEMBLED ON THE METERING UNITS (see

sections 6.12.3 ADJUSTING THE FURROW-OPE-

NER BLADE and 6.14 TURBO DISC OPENER).

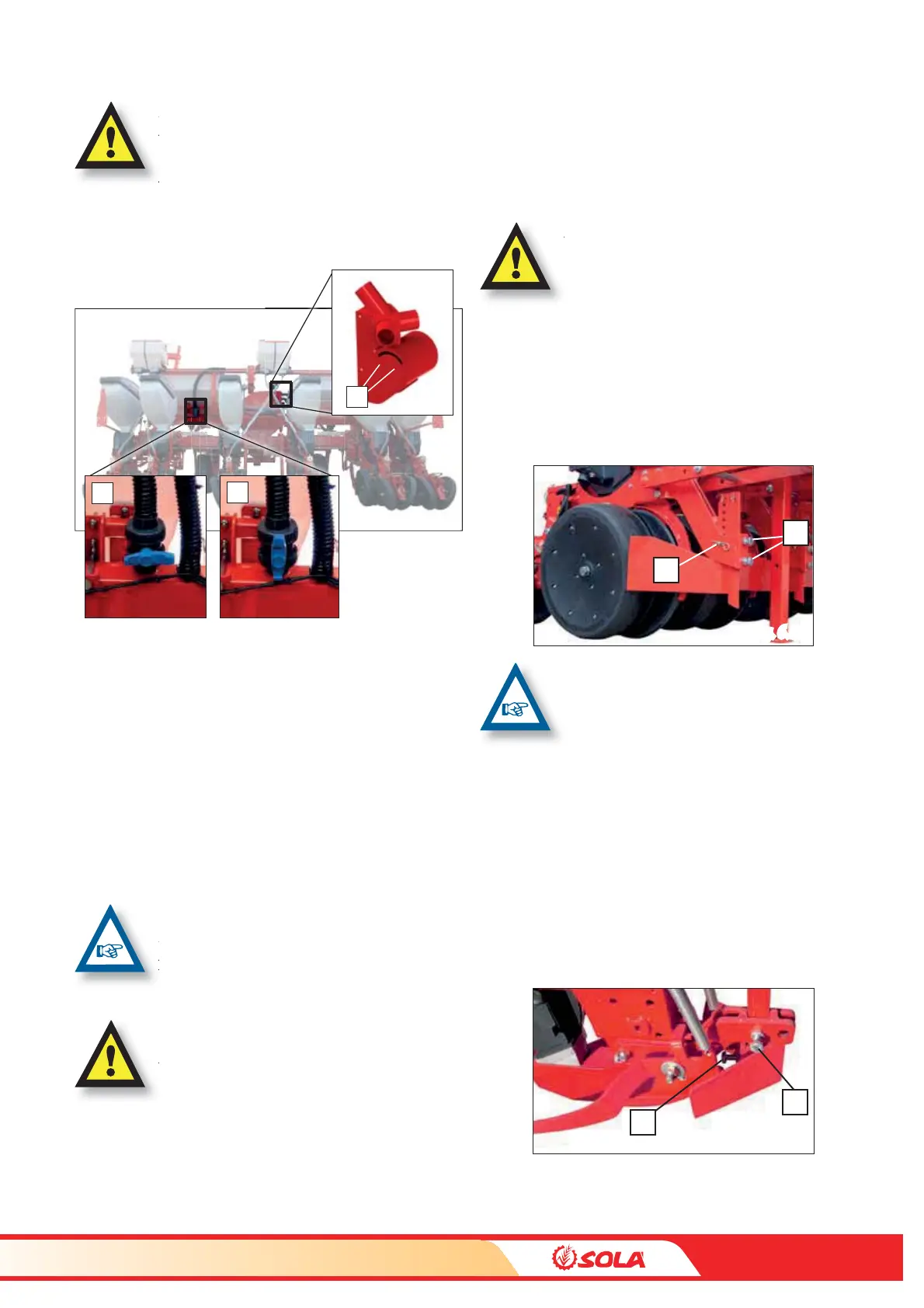

6.12.1 ADJUSTING THE BLADE AND THE

CLOD REMOVER

The depth at which the blade and the clod remover are

going to be buried depends on the type of metering unit:

ATTENTION: ADJUST THE BLADE 1 OR 2 CM

BELOW PLANTING DEPTH.

- METERING UNITS K:

1- Loosen the screws (1, Fig. 6.89) to free the blade and the

clod remover.

2- Remove safety ring and securing bolt (2, Fig.6.89).

3- Place the blade and the clod remover at the desired hei-

ght.

4- Tighten the screws (1, Fig. 6.89) to x both components.

1

Fig. 6.89

2

CLOD REMOVERS CAN BE REPLACED BY DISC OPE-

NERS OR FURROW-OPENER BLADES OR FURROW’S

RESIDUE ROTARY CLEANERS.

- METERING UNITS P:

1- Loosen the screw (B, Fig. 6.90) to free the blade.

2- Place the blade at the desired depth and x it by tighte-

ning the screw (B, Fig. 6.90).

3- Loosen the screw (C, Fig. 6.90) to free the clod remover.

4- Shift the clod remover along the blade until it reaches the

desired height.

5- Fix the clod remover to the blade by tightening the screw

(C. Fig. 6.90).

B

C

Fig. 6.90

Loading...

Loading...