122

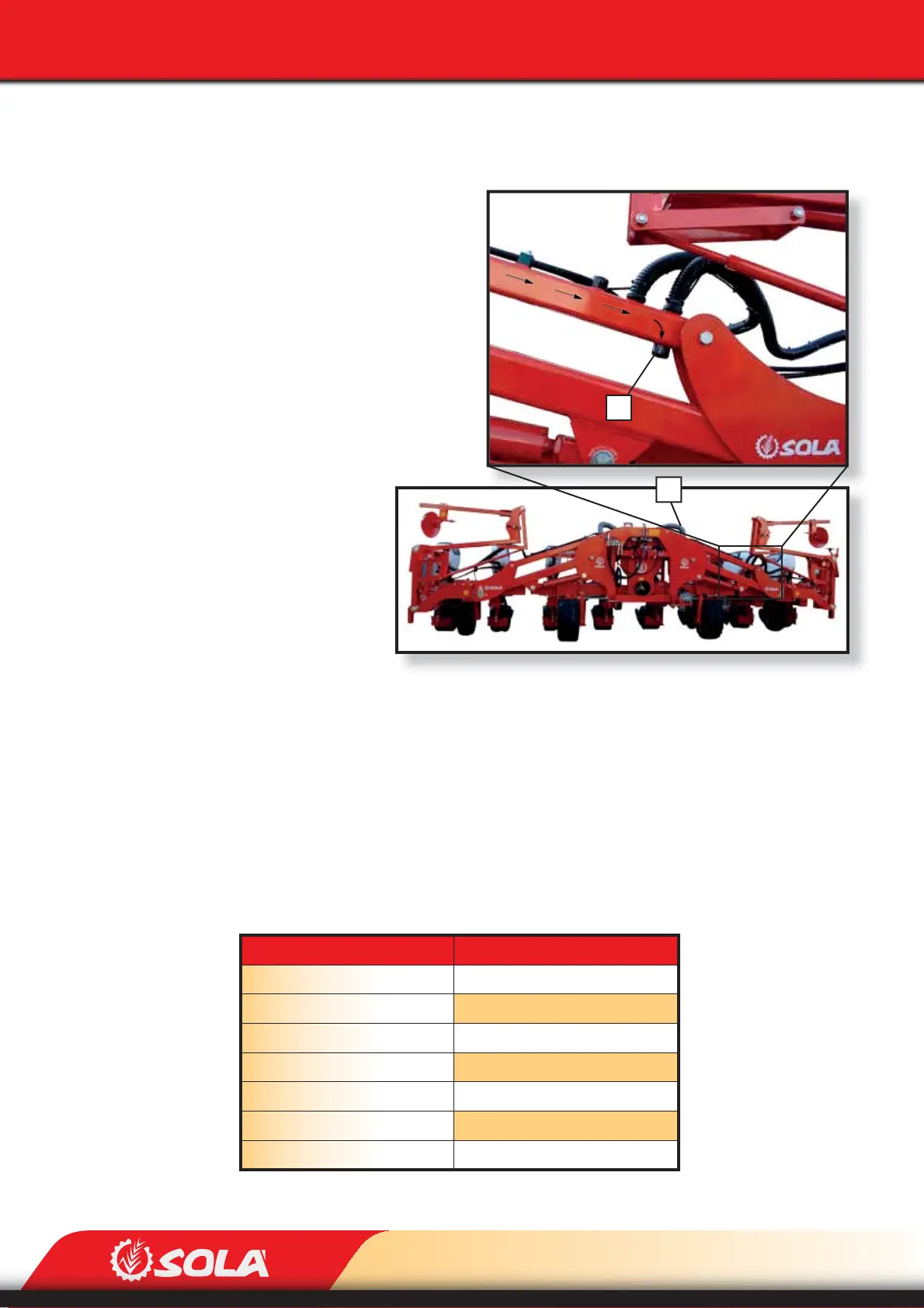

B

Fig. 9.26

A

MAINTENANCE

TYRE TYPE

AIR PRESSURE (bar)

6,5/80 - 15 4PR 1,5

23x8,50 - 12” 4PR 1,5

23x8,50 - 12” 6PR 2

23x8,50 - 12” 8PR 2,5

23x10,50 - 12” 4PR 1,5

23x10,50 - 12” 8PR 2,5

26x12 - 12” 8PR 2,5

In FOLDING versions of the machine, the air reservoir of the folding parts needs to be cleaned as

well. To perform the cleaning, follow these steps:

1- Remove the suction duct that

connects the main air reservoir

to the folding parts’ air reservoir

(A, Fig. 9.24 or 9.26).

2- R

emove the lower cap of the fol-

ding parts’ air reservoir (B, Fig.

9.26).

3- Use compressed air to blow air

into the folding parts’ air reser-

voir in the direction indicated by

the arrows in Fig. 9.26.

4- Place the lower cap back (B, Fig.

9.26) and connect

the suction duct

(A, Fig. 9.26).

9.7 SCREWS

All the securing screws which x the components to the planter need to be checked and tigh-

tened if necessary after the rst 10 hours of work. Especially check the securing screws of the

metering units, the three-point frame, the wheels and the supports of the track markers.

9.8 TYRE PRESSURE

Before starting working with the planter, check that the tyre pressure is correct.

Loading...

Loading...