42

ADJUSTMENTS

6.3 SEED DISTRIBUTION IN THE SEED DISC

The following adjustments aect directly on the quality of the seed dosing:

1. The selector’s position in relation to the disc’s holes. It is important to adjust the selector’s

position depending on the type of seed to be distributed (see section 6.3.1. ADJUSTING THE

SELECTOR).

2. The seed ejector’s position in relation to the disc’s holes. In order to achieve a better seed

dosing, the metering box PROSEM is provided with a seed ejector slide (see 6.3.2 ADJUSTING

THE SEED EJECTOR).

3. The suction power needs to be adjusted to the weight of the seeds to be planted (see section

6.4 SUCTION SYSTEM – FAN).

IN ORDER TO GET AN EVEN AND PRECISE SOWING, IT IS RECOMMENDED TO NOT SURPASS 9

KM/H IN MACHINES PROSEM K AND 6 KM/H IN MACHINES PROSEM P.

6.3.1 ADJUSTING THE SELECTOR

The selector’s lever can be adjusted from 0 to 10. When the lever is placed at a higher number,

the selector is being moved away from the hole and, therefore, the suction power is increased.

This causes a tendency towards the emergence of doubles. On the other side, when the lever

is placed at a lower number, the selector is being moved closer to the hole and, therefore, the

suction power is reduced. This causes a tendency towards the lack of seeds in the disc’s hole.

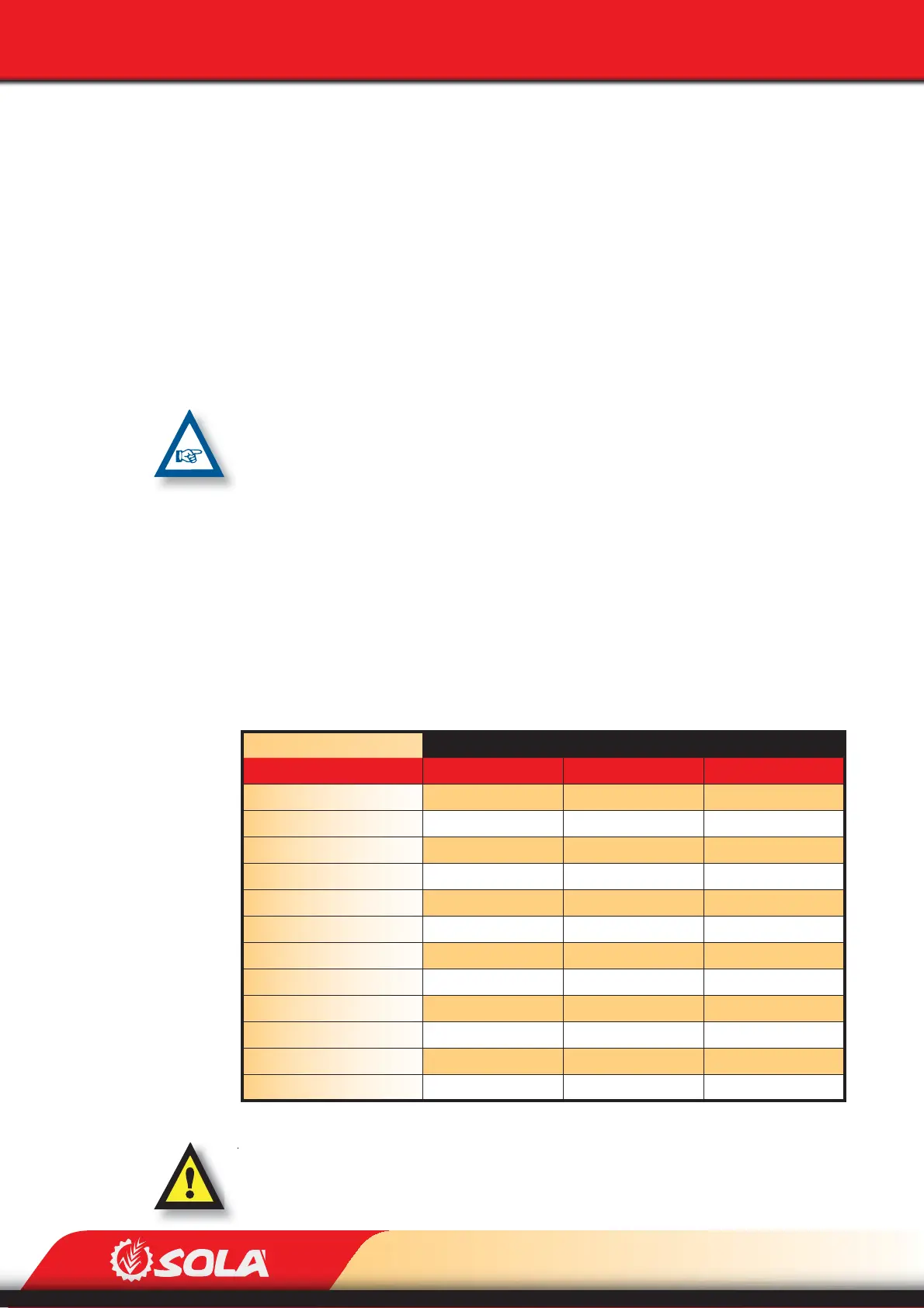

Recommended selector’s positions depending on the type of seed to be planted using stan-

dard seed discs (see section 3.6 Metering Box).

* Using a special selector.

THE SELECTOR’S POSITIONS INDICATED ABOVE ARE APROXIMATIVE; IT IS ESSENTIAL TO PER-

FORM TESTS AT THE BEGINNING AND DURING THE SOWING SEASON.

VALOR SELECTOR

TYPE OF SEED MINIMUM MAXIMUM RECOMMENDED

Sorghum 2,4 3,2 2,8

Sunower 2,4 3,2 2,8

No-pilled sugar beet 2,6 3,4 3

Rape 2,8 3,6 3,2

Corn 3,1 3,9 3,5

Small Corn 2,8 3,6 3,2

Soya / Peas 3,1 3,9 3,5

Pilled sugar beet 3,1 3,9 3,5

Cotton 4,6 5,4 5

Beans 4,6 5,4 5

Chick peas 6,6 7,4 7

Broad beans (*) 9,6 10,4 10

Loading...

Loading...