118

1

1

1

1

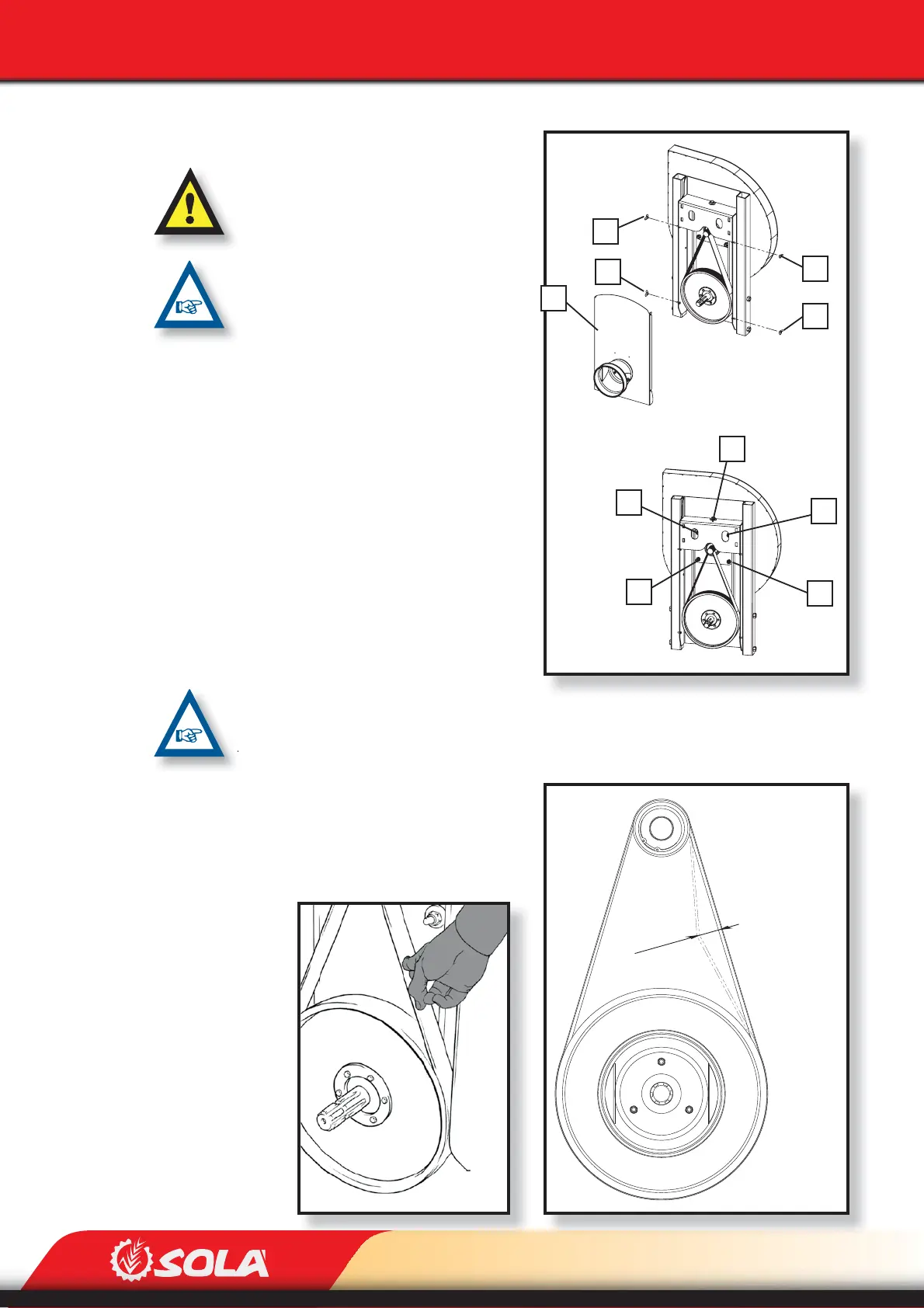

Fig. 9.14

3

3

2

4

3

3

Fig. 9.15

MAINTENANCE

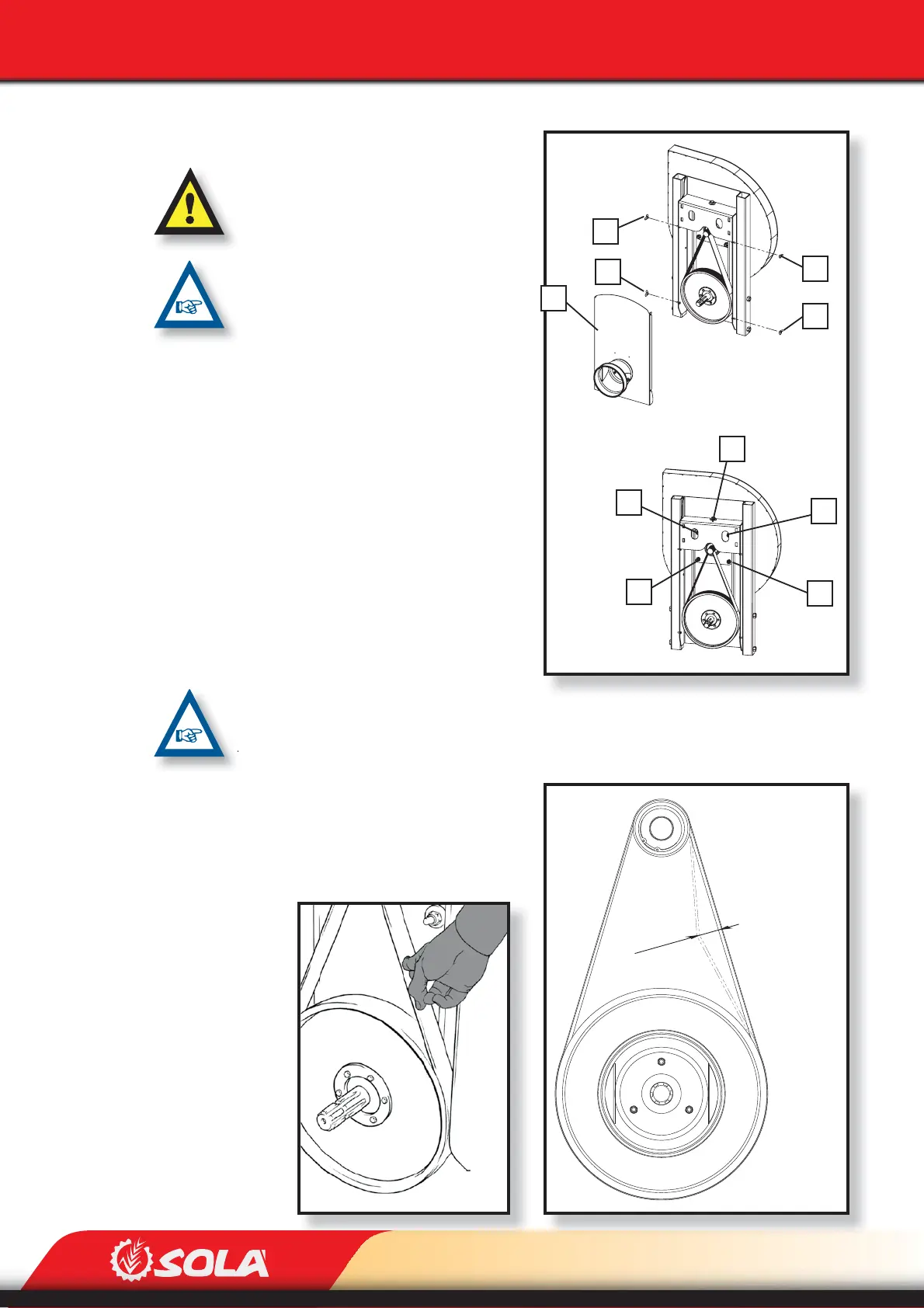

2 mm

5 kg Push force

Fig. 9.16

9.3 FANS

KEEP THE AIR OUTLETS FREE.

BEFORE STARTING THE SOWING SEASON,

CHECK THAT THE DUCTS OF THE AIR CIR-

CUIT ARE IN GOOD CONDITION.

Mechanical fans

Check the condition of the timing belts sin-

ce natural wear may cause looseness.

To extend the service life of the timing belt,

the machine is equipped with a tensioning

system. To adjust it, follow these steps:

1- Loosen the wing nuts (1, Fig. 9.14) in or-

der to remove the transmission’s lid (2,

Fig. 9.14).

2- Loosen the four nuts of the tensioner (3,

Fig. 9.14).

3- Operate on the screw (4, Fig. 9.14) to ad-

just the tension of the belt.

CHECK THE TENSION OF THE TIMING BELT

BY PRESSING ON IT (FIG. 9.15). CHECK THAT ITS TENSION IS OPTIMAL BY APPLYING A 5 KG LOAD

ON THE POINT THAT IS EQUIDISTANT FROM THE PULLEYS’ AXLES. IF THE TENSION IS OPTIMAL,

THE TIMING BELT SHOULD SHIFT 2 MILLIMETRES AS A CONSEQUENCE OF APPLYING THIS PUSH

FORCE (Fig. 9.16).

4- Tighten the nuts (3, Fig. 9.14) to lock the

pulley’s position.

5- Place the lid back and tighten the wing

nuts (1, Fig. 9.14).

Loading...

Loading...