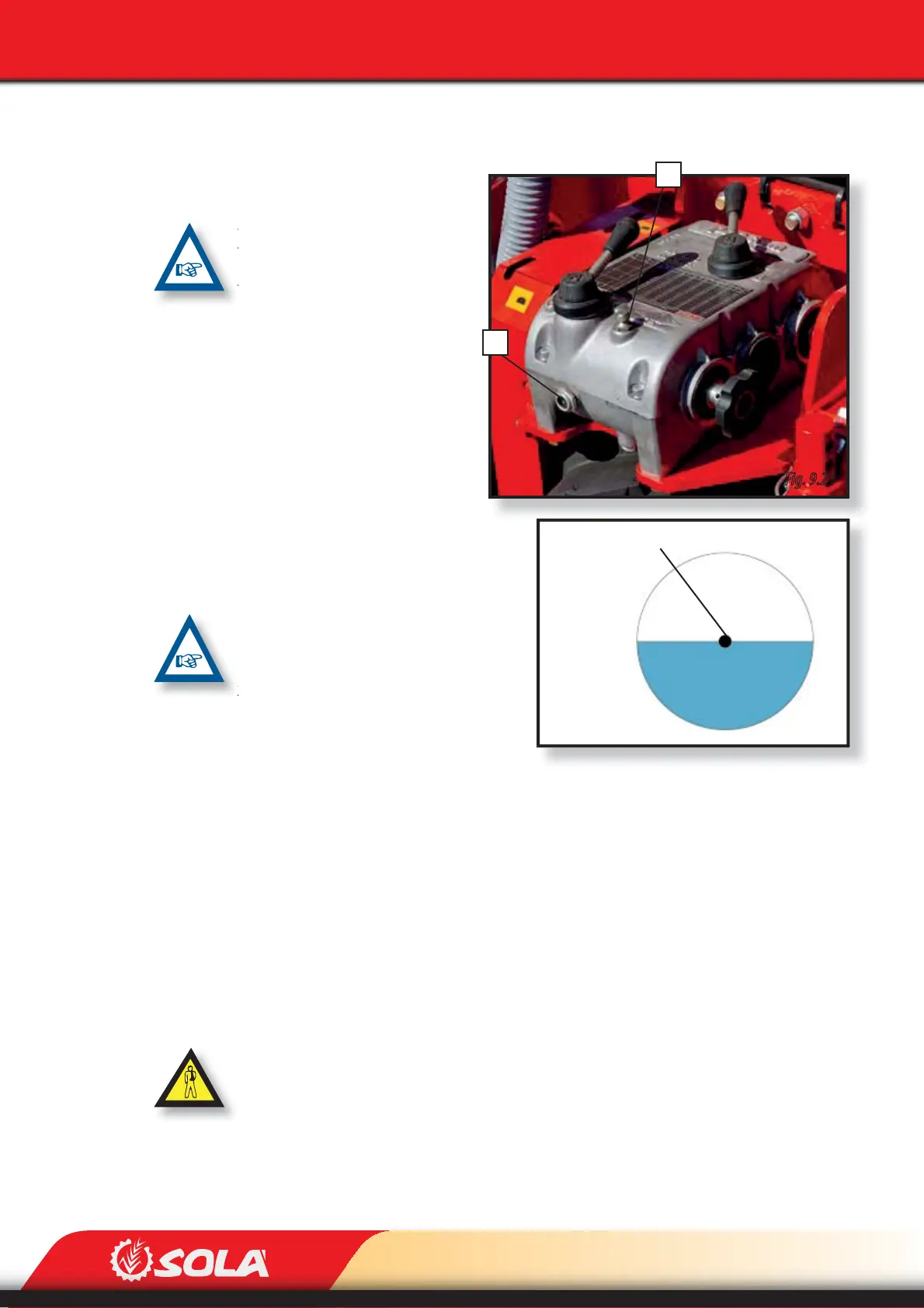

120

1

2

Fig. 9.21

MAINTENANCE

9.5 AUTOMATIC GEARBOX

Periodically check the oil level of the gearbox

using the oil sight glass (1, Fig. 9.21).

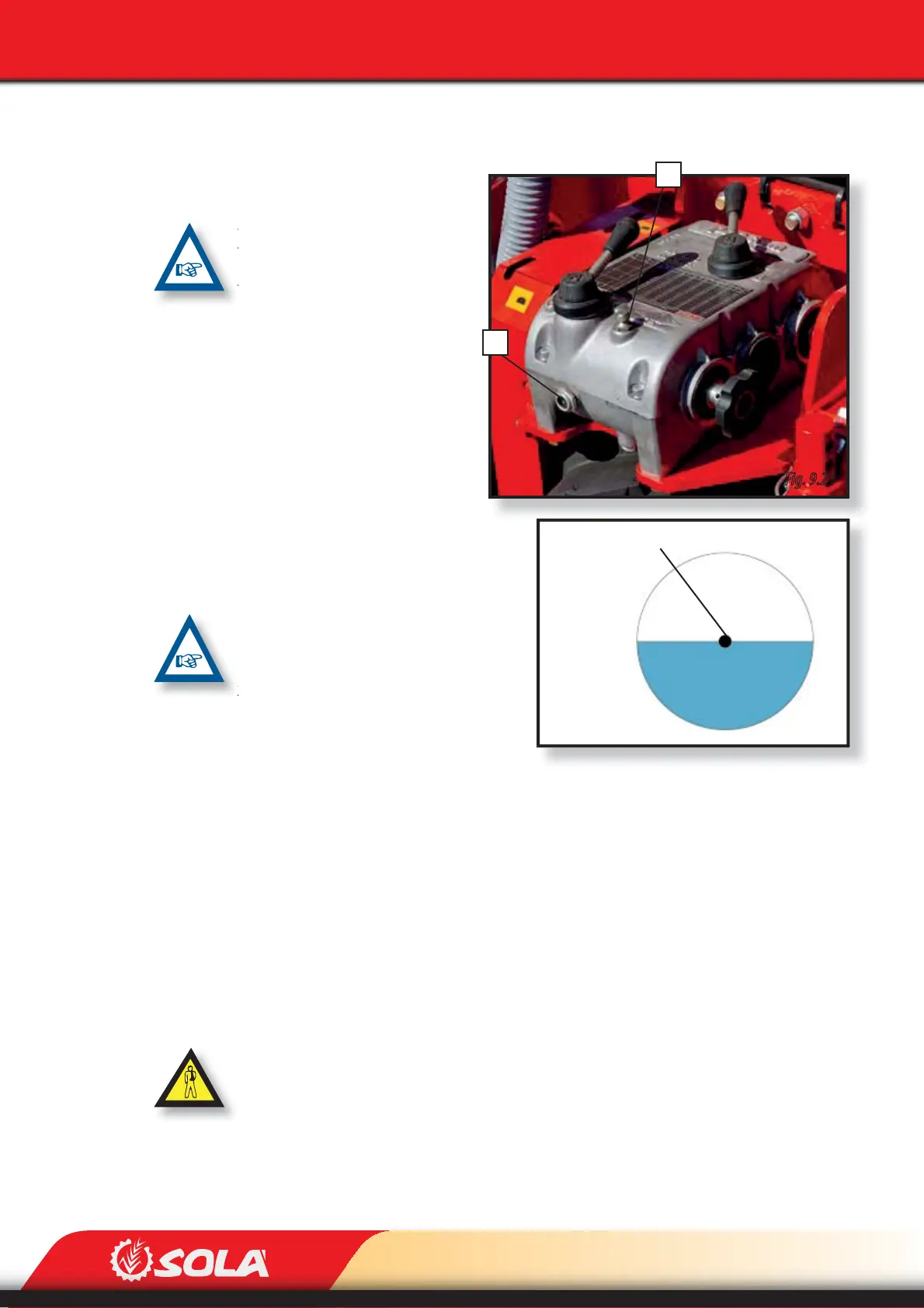

WHEN THE OIL LEVEL REACHES

THE MARK IN THE CENTRE OF THE

OIL SIGHT GLASS, THAT MEANS

THAT THE OIL LEVEL IS OPTIMAL

(Fig. 9.22).

To ll the oil tank:

1- Remove the cap (2, Fig. 9.21)

2- Fill the tank. Check the level using the oil si-

ght glass (1, Fig. 9.21).

3- Place the cap back.

IT IS RECOMMENDED TO CHANGE THE OIL

EVERY 5 YEARS, REGARDLESS OF THE USE

OF THE PLANTER. TO CHANGE THE OIL,

ALWAYS USE OIL TYPE SAE 30 (APPROXIMA-

TELY 2 LITRES).

9.6 MACHINE CLEANING

The planter should be washed using a water jet or preferably using a high-pressure cleaner. Let

the planter dry before greasing or lubricating to prevent the metallic parts from rusting.

After washing the machine, turn on the fan for some minutes in order to remove the moisture

from the metering units and the suction system.

It may be possible that, while working, some foreign bodies are stuck in some parts of the plan-

ter, such as the fertilizer’s discs and the seed discs. Check that these discs are turning properly.

Otherwise, take the component apart and remove any foreign body.

EVERY TIME THE SEED HOPPER IS CLEANED USING COMPRESSED AIR, USE PROPER PERSONAL

PROTECTIVE EQUIPMENT (PPE) (see section 9- MAINTENANCE).

Optimal level

Oil

Level mark

Fig. 9.22

Loading...

Loading...