Operation 5

Refuelling

– Observe the safety guidelines for vehicles

powered by LPG and the safety instructions

posted at the filling station.

The LPG tank may only be filled by trained

personnel.

The LPG tank can only be filled at LPG filling

stations that do not require authorisation.

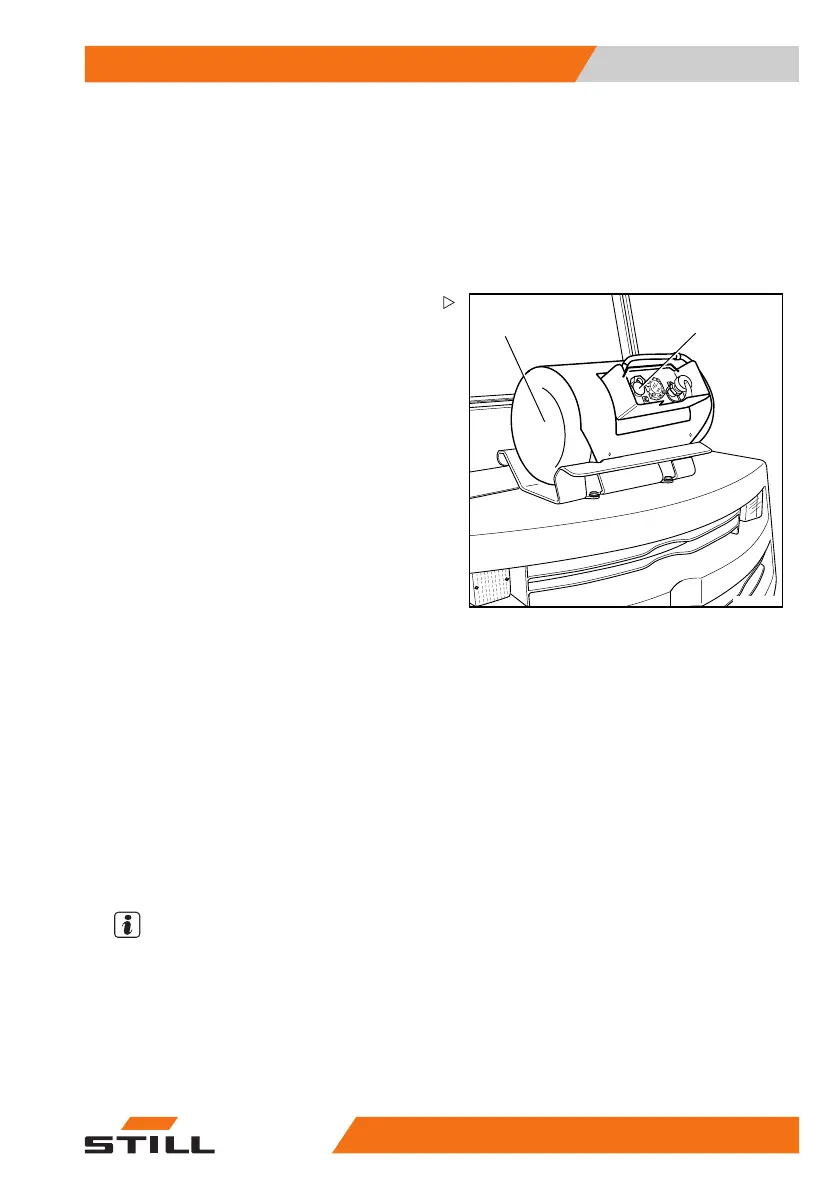

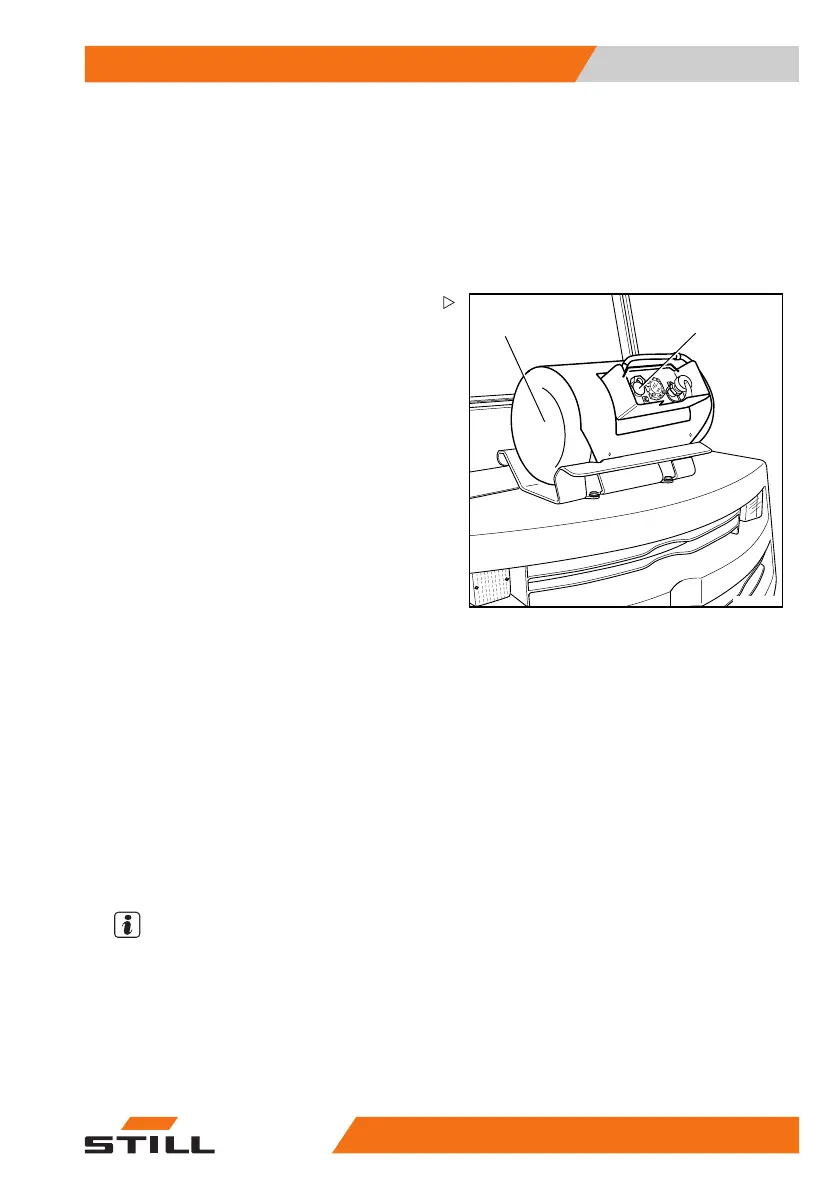

7081_003-028

1

2

– Before connecting the filler nozzle, check

whether the LPG tank (1) or fittings (2) show

any defects and that the inspection interval

given on the container has not expired.

Inspection intervals required in the Pressure

Vessels Regulations must be complied with.

The most recent inspection date marked on

the container is the applicable date. Contain-

ers with an expired inspection date should not

be used. Follow the national regulations for

your country.

Filling may not be carried out if defects are

observed or if the inspection interval has been

exceeded.

Pipework and its accessories for gas in the

liquid phase and LPG containers must not be

exposed to an impermissible level of heat.

Explosions involving gas cylinders or LPG

systems must be immediately reported to the

employers’ liability insurance association and

the industrial inspectorate responsible, even

where no accident occurs (applies to Ger-

many). Damaged parts must be kept until

conclusion of the investigation. Follow the na-

tional regulations for your country.

Removable LPG containers may only be

changed in storage rooms when there is no

possibility of a hazardous explosive atmos-

phere being produced.

NOTE

We recommend that you refuel before starting

work if the machine is still cold. If there is a

major difference in temperature between the

storage tank out in the open and the tank on

the truck, the delivery pressure of the pump

may no longer be sufficient for proper filling.

– Switch off the engine and heater.

171673 [EN] 169

Loading...

Loading...