Maintenance 6

Maintenance as required

Maintaining hydraulic equipment

WARNING

Hydraulic oils are hazardous to your health and are

under pressure during operation.

Note safety regulations for working with hydraulic

oils; see ⇒ Chapter "Hydraulic fluid", P. 3-33.

7071_003-072

1

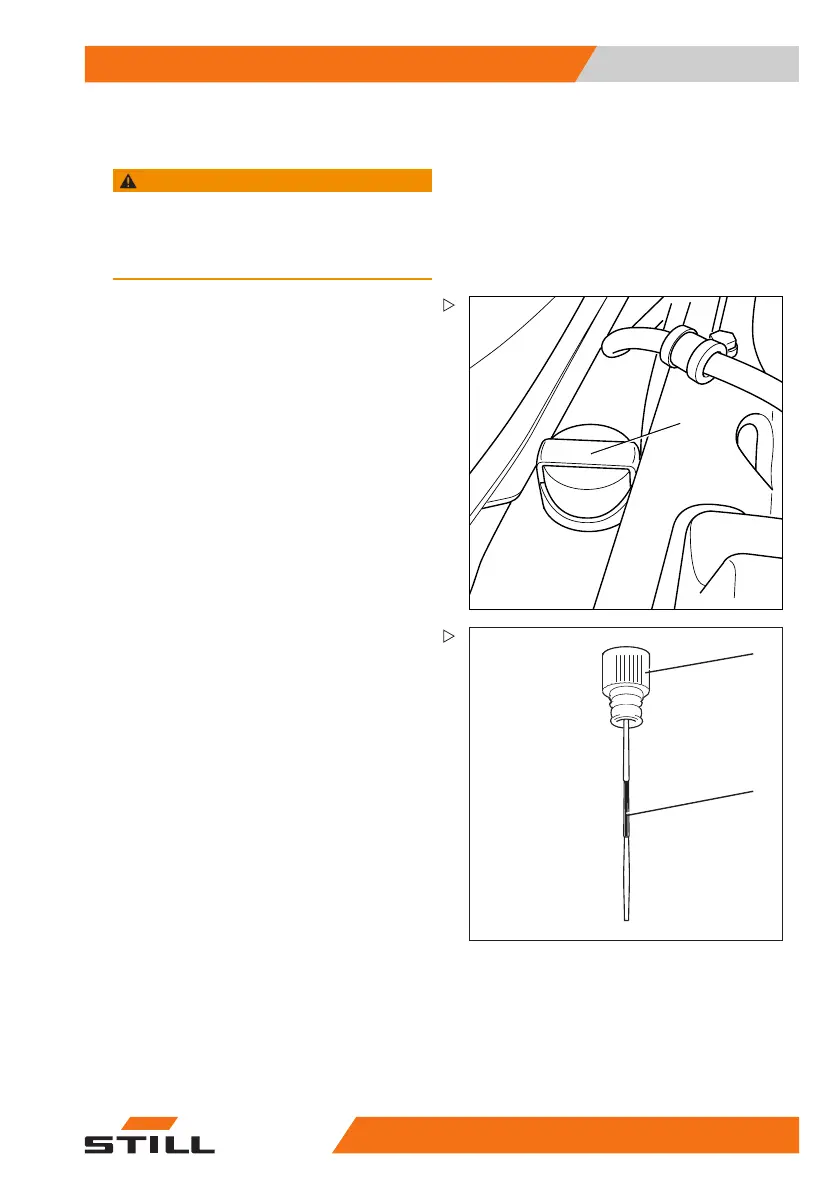

Check hydraulic oil level

– Position truck horizontally.

– Tiltliftmastforward.

– Lower forks; if there are attachments (spe-

cial equipment), retract the working cylin-

der.

– Switch off the engine.

– Open the bonnet; see ⇒ Chapter "Opening

the bonnet", P. 5-55.

– Disassemble base plate; see ⇒ Chap-

ter "Installing and removing the floor-

plate", P. 6-194.

– Unscrew (1) the dipstick and pull it out.

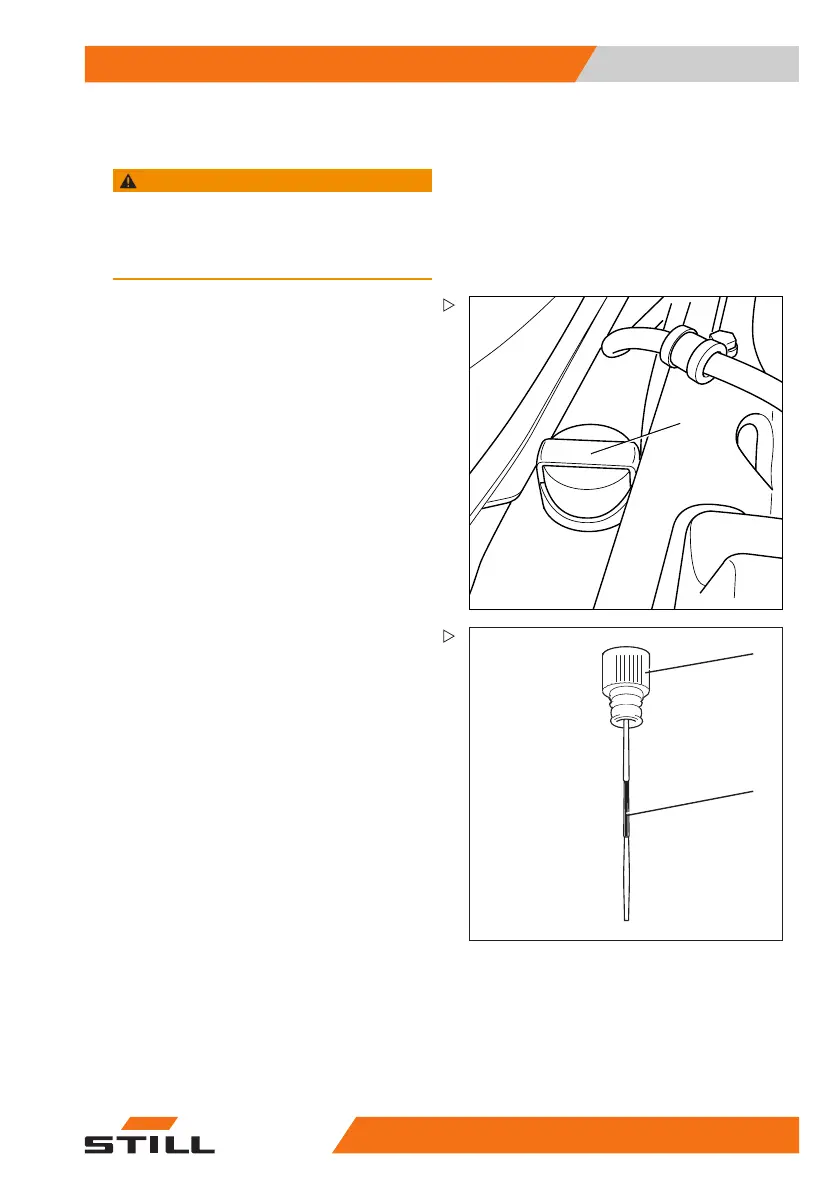

7094_700-002

1

2

– Check oil level. The oil level must be at least

up to the mark (2) on the dipstick.

– If the oil level is not up to the required level,

the hydraulic oil must be topped up ac-

cording to the maintenance data table

(see ⇒ Chapter "Maintenance data ta-

ble", P. 6-186) using the filler neck until

the mark is reached.

– Reinsert (1) the dipstick and tighten it.

Checking hydraulic equipment for leaks

– Check pipe and hose screw connections for

leaks (traces of oil).

Hose lines must replaced if:

• the outer layer is damaged or embrittled

with cracks

• they are leaking

• Unnatural deformations (e.g. bubble forma-

tion or buckling

• fitting is detached from hose

• heavy damage to or corrosion of the fitting

171673 [EN] 207

Loading...

Loading...