Maintenance 6

1000-hour maintenance/annual maintenance

1000-hour maintenance/annual maintenance

Work that must also be carried out

– Carry out maintenance work as neces-

sary, see ⇒ Chapter "Maintenance as re-

quired", P. 200.

– Carry out 500-hour maintenance,

see ⇒ Chapter "500-hour mainte-

nance/semi-annual maintenance", P. 222.

Maintainance of drive axle

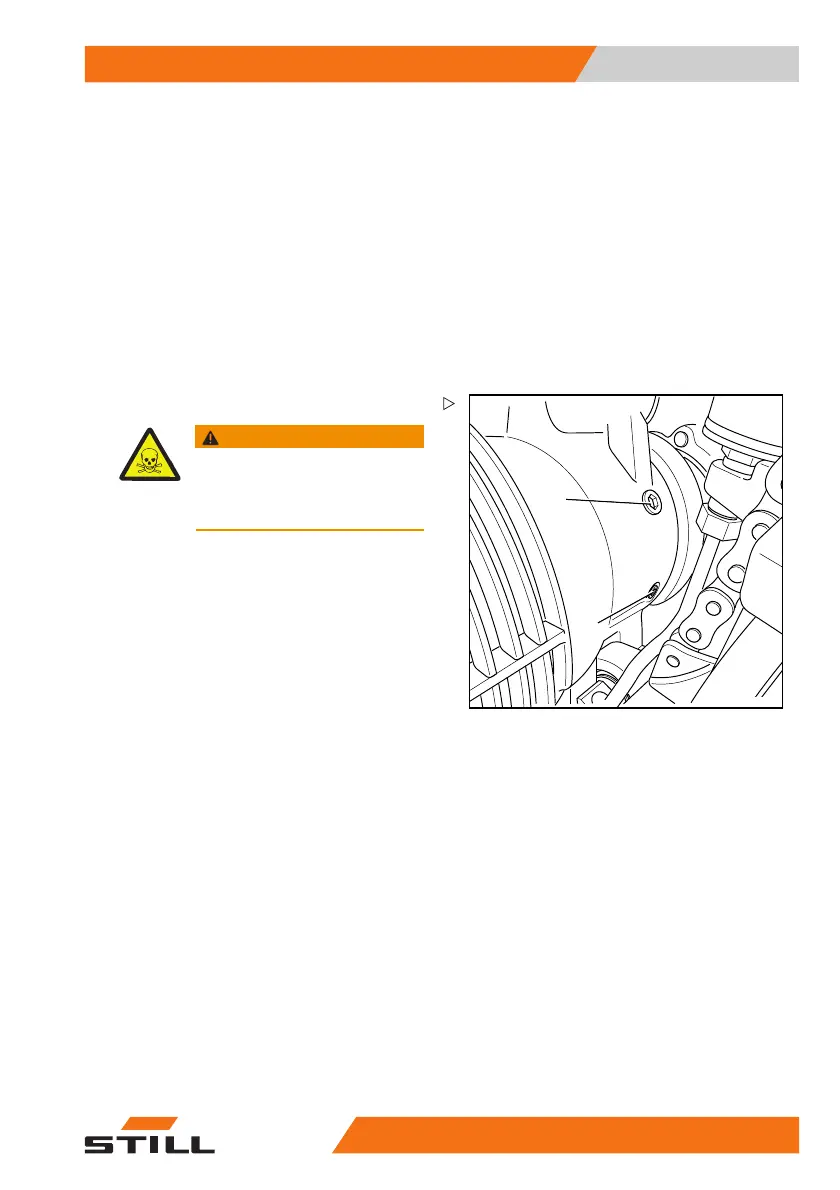

7071_003-076

1

2

Drive axle, checking oil level

WARNING

Consumables are toxic!

Observe the safety regulations for

handling brake fluid,see ⇒ Chap-

ter "Oils", P. 3-29.

– Park the forklift on a level surface.

– Unscrew the checking (1)screw.

The oil level must reach the lower edge of the

bore.

– Unscrew the filling plug, if necessary, (2)

and fill with oil as per the maintenance data

table; see ⇒ Chapter "Maintenance data

table", P. 6-186 until it escapes from the

hole for the checking screw (1).

– Renew the sealing ring on the oil drain plug

(1).

– Tighten the oil checking screw (1) with a

torque of 10 Nm.

– Renew the sealing ring on the oil drain plug

(2).

– Tighten the oil drain plug (2) with a torque of

24 Nm.

– Check the oil level at both wheel drives.

Checking the drive axle for leaks

– Inspect the power unit for leaks (traces of

oil).

171673 [EN] 223

Loading...

Loading...