5-56 4252490-Rev A

HYDROSTATIC POWER TRAIN

5

6. Disconnect hoses (4 and 5) from flushing valve

assembly (6).

7. Support flushing valve assembly (6).

8. Remove three mounting screws (3).

9. Remove flushing valve assembly (6).

Installation Notes

• Install flushing valve by reversing the order of

removal.

• Lubricate all O-rings prior to assembly.

• Make sure new O-rings are in place before installing

hoses on fittings.

• Replace hydraulic oil charge filter. (See “Hydraulic

Oil Charge Filter Assembly” on page 6-59.)

• Refill hydraulic oil tank. (Refer to “Parts and

Maintenance Manual” for correct oil specifications.)

• Start engine. Check hydraulic system for leaks.

Repair as necessary.

• Check hydraulic oil level and add if necessary.

Disassembly, Inspection, and Assembly

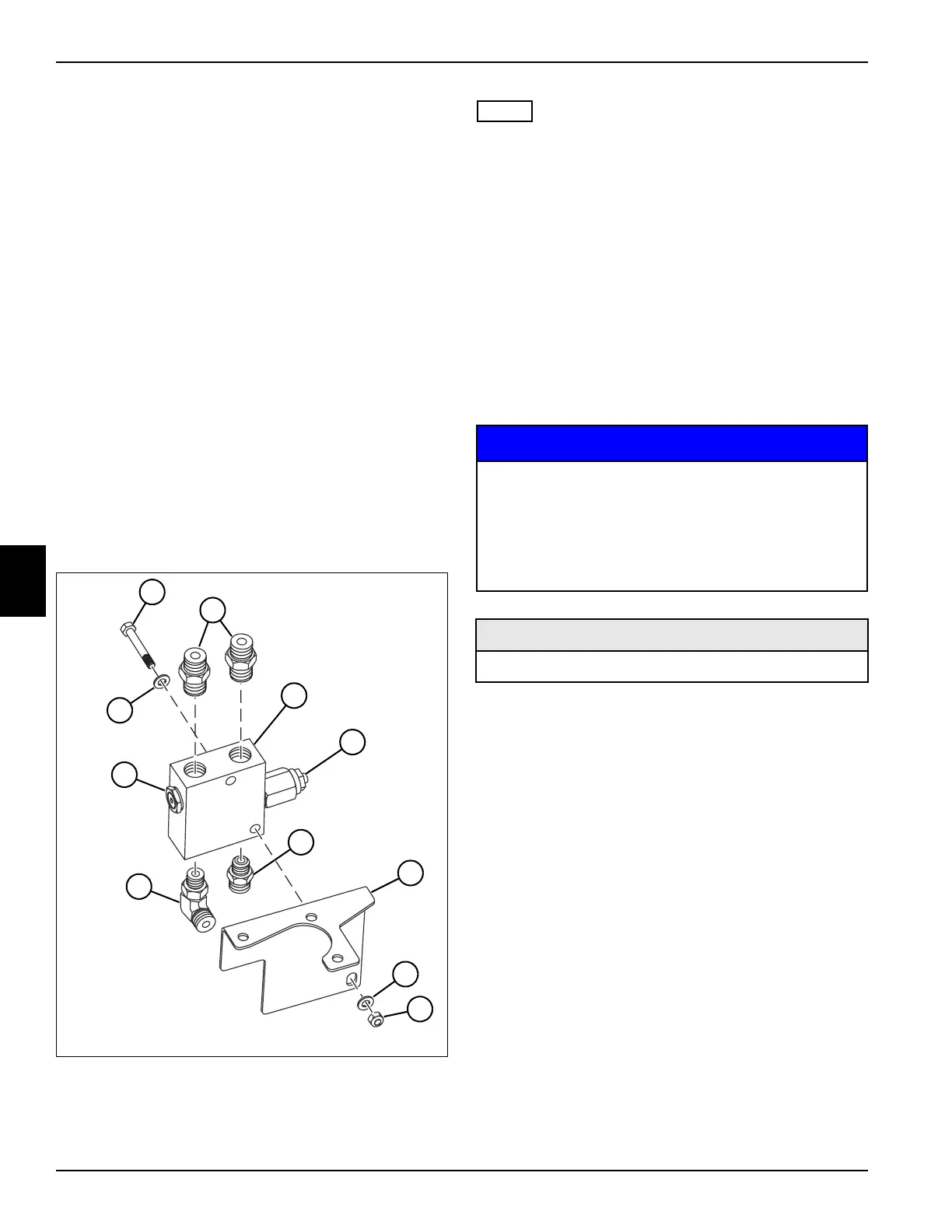

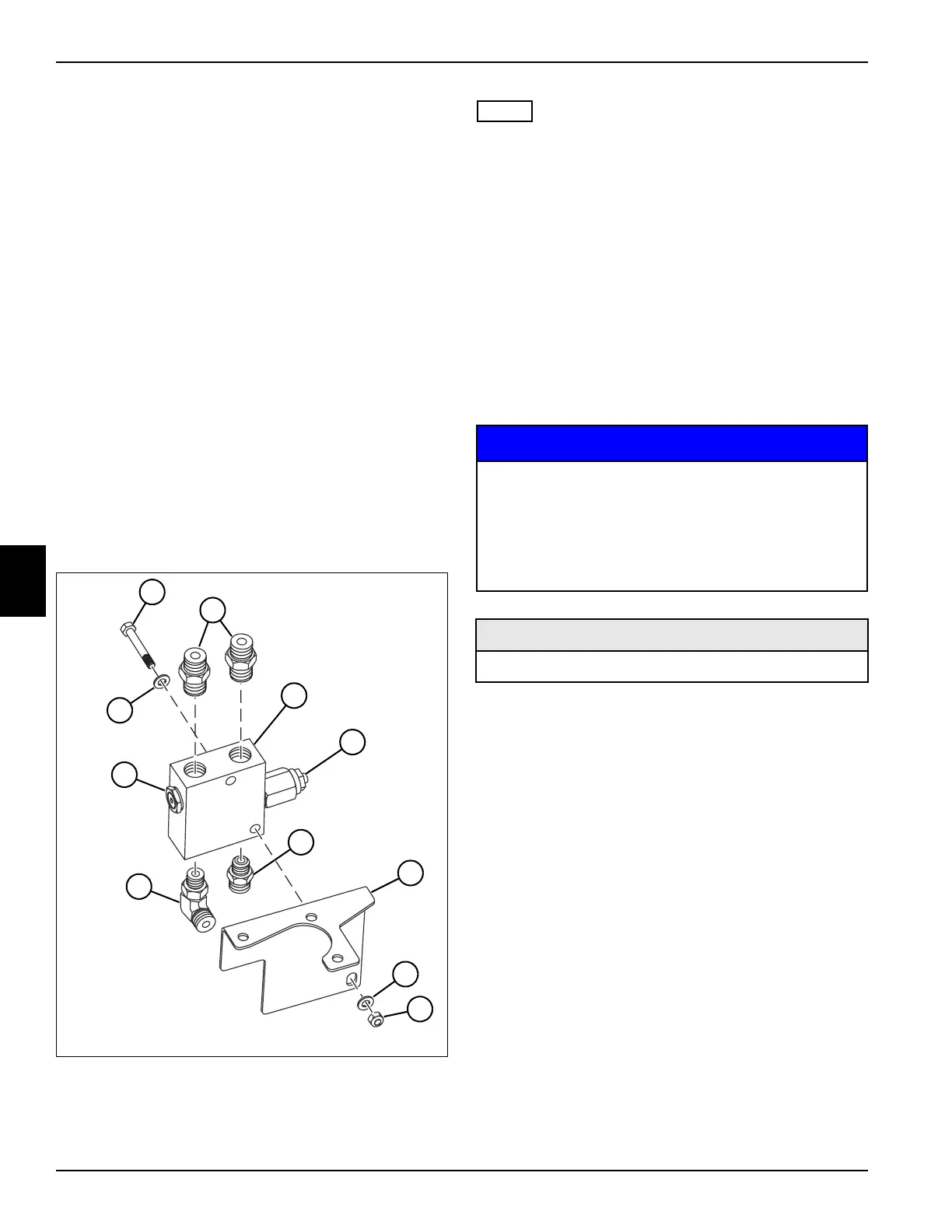

See Figure 5-56.

Figure 5-56

1. Remove two nuts (8), washers (7), washers (11), and

screws (1), and remove flushing valve (3).

NOTE

Record the location of fittings before removing to ensure

correct installation.

2. Remove, inspect, and replace fittings (2) for ports

“RW1” and “RW2” as necessary.

3. Remove, inspect, and replace fitting (5) for port “DR”

as necessary.

4. Remove, inspect, and replace fitting (9) for port “PP”

as necessary

5. Clean all parts using clean solvent, and dry using

compressed air.

6. Inspect all parts for wear or damage. Replace as

necessary.

Assembly Notes

NOTICE

• Assemble the flushing valve by reversing the order of

disassembly.

• Use a new seal kit during assembly.

• Lubricate all O-rings prior to assembly.

• Tighten relief valve (4) to 44 lb-ft (60 N·m).

• Tighten check valve (10) to 44 lb-ft (60 N·m).

• Tighten fittings (2) for ports “RW1” and “RW2” to

77 lb-ft (105 N·m).

• Tighten fitting (5) for port “DR” to 27 lb-ft (37 N·m).

• Tighten fitting (9) for port “PP” to 27 lb-ft (37 N·m).

TN3916

1

2

11

5

6

9

7

8

3

4

10

It is important that all component parts are

absolutely clean, as contamination can result in

serious damage and/or improper operation.

Never use shop towels or rags to dry parts after

cleaning, as lint may clog passages. Dry parts

using compressed air.

Required Materials

•Seal Kit

Loading...

Loading...