5-68 4252490-Rev A

HYDROSTATIC POWER TRAIN

5

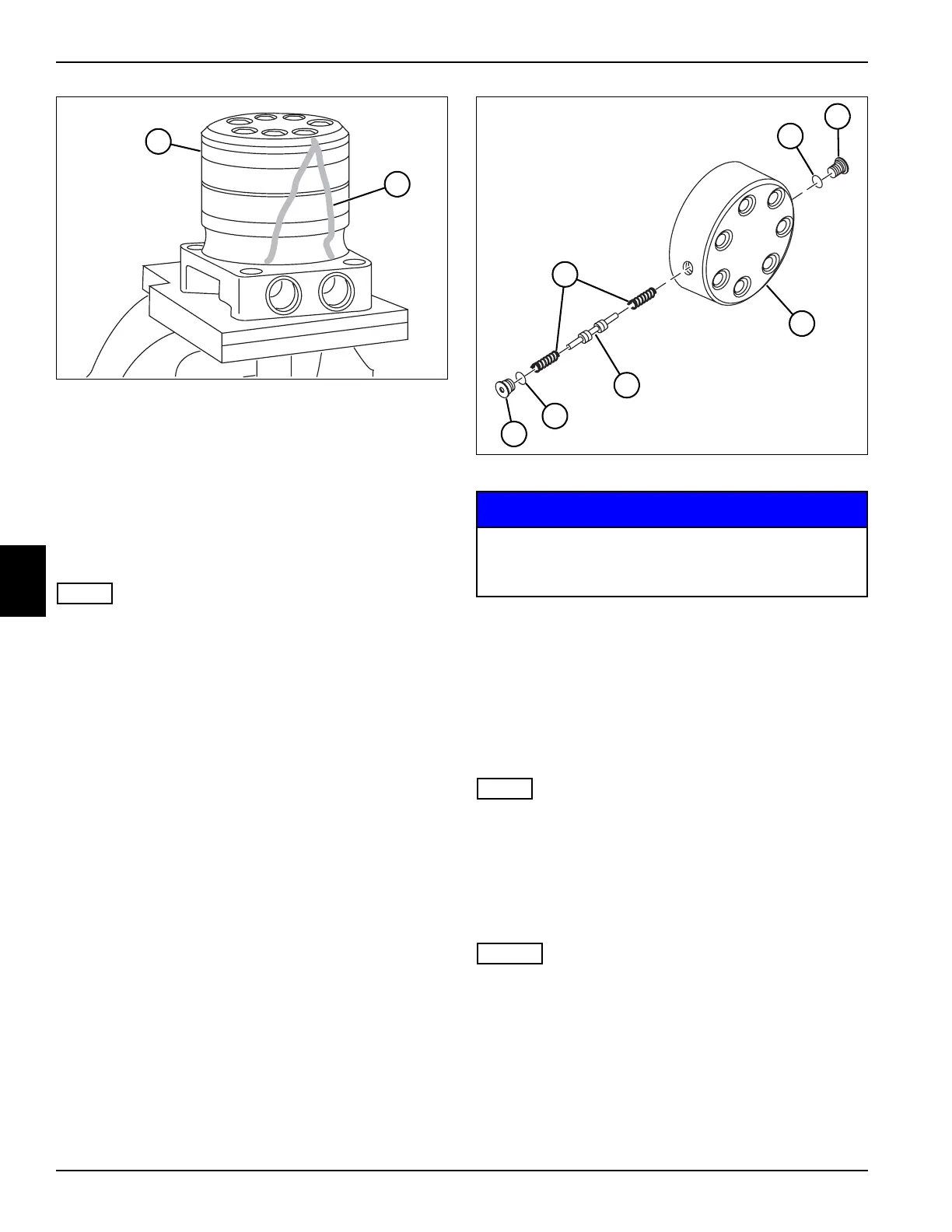

Figure 5-71

1. Place wheel motor (28) in a soft-jawed vice, with the

coupling shaft pointed down and the vise jaws firmly

clamping each side of the housing mounting flange.

2. Scribe or mark lines (29) across the side of wheel

motor sections to mark the position and orientation of

motor segments before disassembly.

3. Loosen, but do not remove, the two shuttle valve

plugs (24 and 27).

NOTE

Use caution when removing screws, as motor segments

will be free to move.

4. Remove seven screws (25) from end cover (23).

5. Inspect screws (25) and seal rings (26) for damage.

Replace as needed.

6. Remove end cover (23) and seal ring (14) from

commutator (20) and commutator ring (22).

7. Inspect the surface of the end cover that makes

contact with commutator and commutator ring. A

polished pattern (not scratches) from the commutator

is normal. Discoloration indicates excess fluid

temperature, thermal shock, or excess speed and

requires inspection of the end cover, commutator,

manifold, and rotor set. Replace as needed.

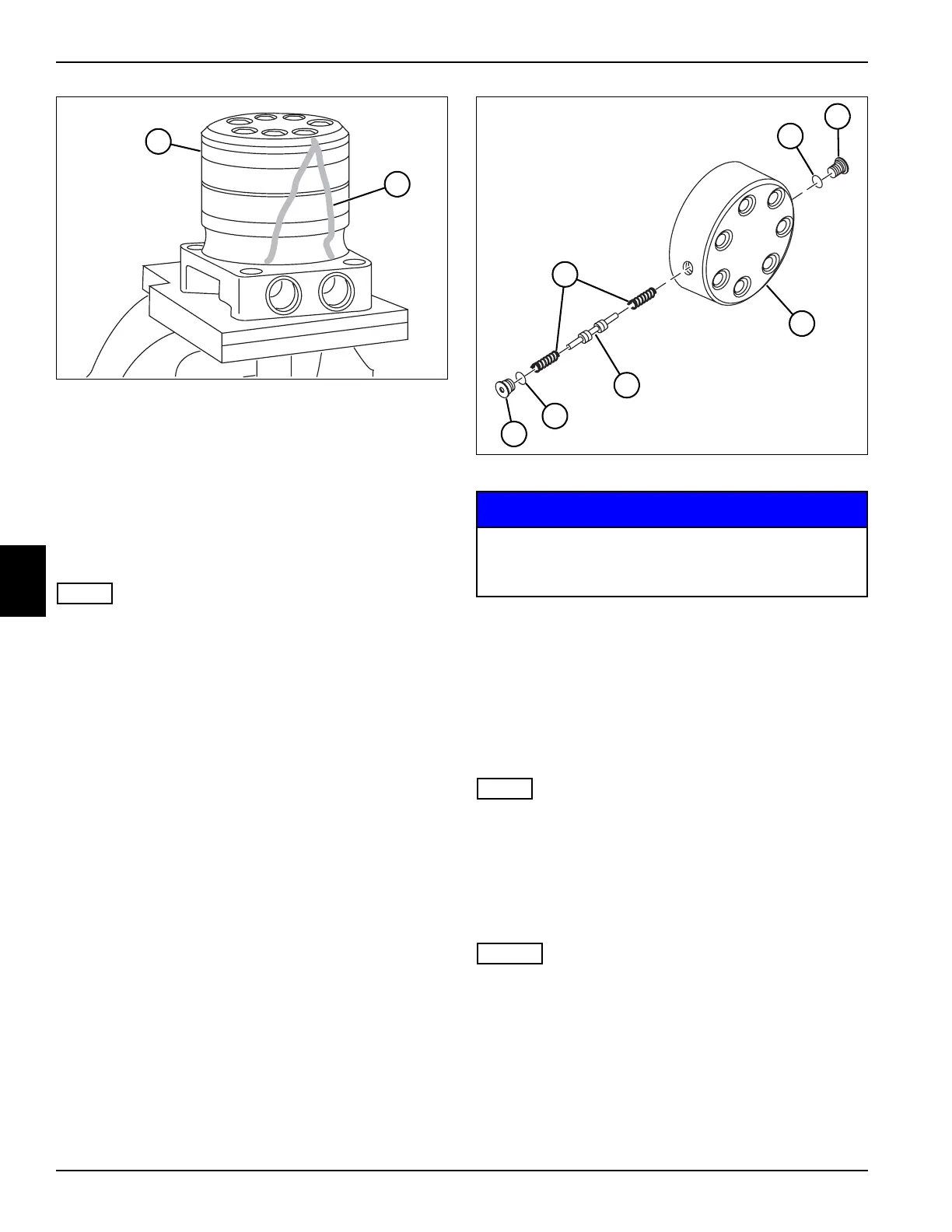

Figure 5-72

NOTICE

8. Remove two shuttle valve plugs (24 and 27) and

O-rings (30 and 32).

9. Remove shuttle valve (31) and two springs (33).

10. Remove commutator ring (22) and commutator (20).

11. Remove seal ring (21) from commutator (20) using

compressed air to blow air into the ring groove until

the seal ring is lifted out of the groove.

NOTE

If any damage or wear is noticed in the commutator or

commutator ring, both must be replaced as a matched

set.

12. Inspect commutator ring (22) for cracks or burrs.

13. Inspect commutator (20) for cracks, burrs, wear,

scoring, spalling, or brinelling.

NOTES

• The manifold is constructed of plates bonded

together to form an integral component and must not

be disassembled.

• Compare the configuration of each side of the

manifold and note which side of the manifold is

positioned against the rotor set to ensure correct

installation.

14. Remove manifold (19).

TN3890

28

29

Shuttle valve components are spring-loaded and

will fall out as the plugs are removed. Remove

plugs slowly, and be ready to catch components.

TN3898

~

30

24

3

33

31

32

27

Loading...

Loading...