TR-Electronic GmbH 2019, All Rights Reserved Printed in the Federal Republic of Germany

Page 28 of 154 TR - ECE - BA - GB - 0139 - 02 11/21/2019

4.1.3 Device identification

Each PROFINET IO device has a device identification. It consists of a Vendor ID and a manufacturer-

specific part, the Device ID. The Vendor ID is assigned by the PNO and for TR-Electronic has the

value 0x0153, while the Device ID has the value 0x0404.

During start-up the configured device identification is checked and any configuration errors are

detected.

4.1.4 PROFINET IO data exchange

PROFINET IO communication process:

The IO controller establishes, according to its parameterization, one or more application relationships

with the IO devices. To do this it searches for the parameterized names of the IO devices in the

network and assigns an IP address to the found devices. The DCP “Discovery and Control Program”

service is used for this purpose. The IO controller then transmits the desired degree of expansion

(module/submodule) and all parameters for the parameterized IO devices during the next start-up.

The cyclical IO data, alarms, acyclical services and cross-connections are defined.

PROFINET IO allows the transmission velocity of the individual cyclical data to be set by way of a

scaling factor. After parameterization the IO data are transmitted by the IO device in a fixed cycle after

a one-time request by the IO controller. Cyclical data are not acknowledged. Alarms, on the other

hand, must always be acknowledged. Acyclical data are also acknowledged.

To protect against parameterization errors, the expected and actual configuration are compared with

regard to device type, order number and input and output data.

On successful start-up the IO devices start the data transmission automatically. The communication

relationship in PROFINET IO always follows the provider-consumer model. During cyclical

transmission of the measured value, the IO device is the provider of the data, and the IO controller

(e.g. a PLC) is the consumer. The transmitted data are always given a status (good or bad).

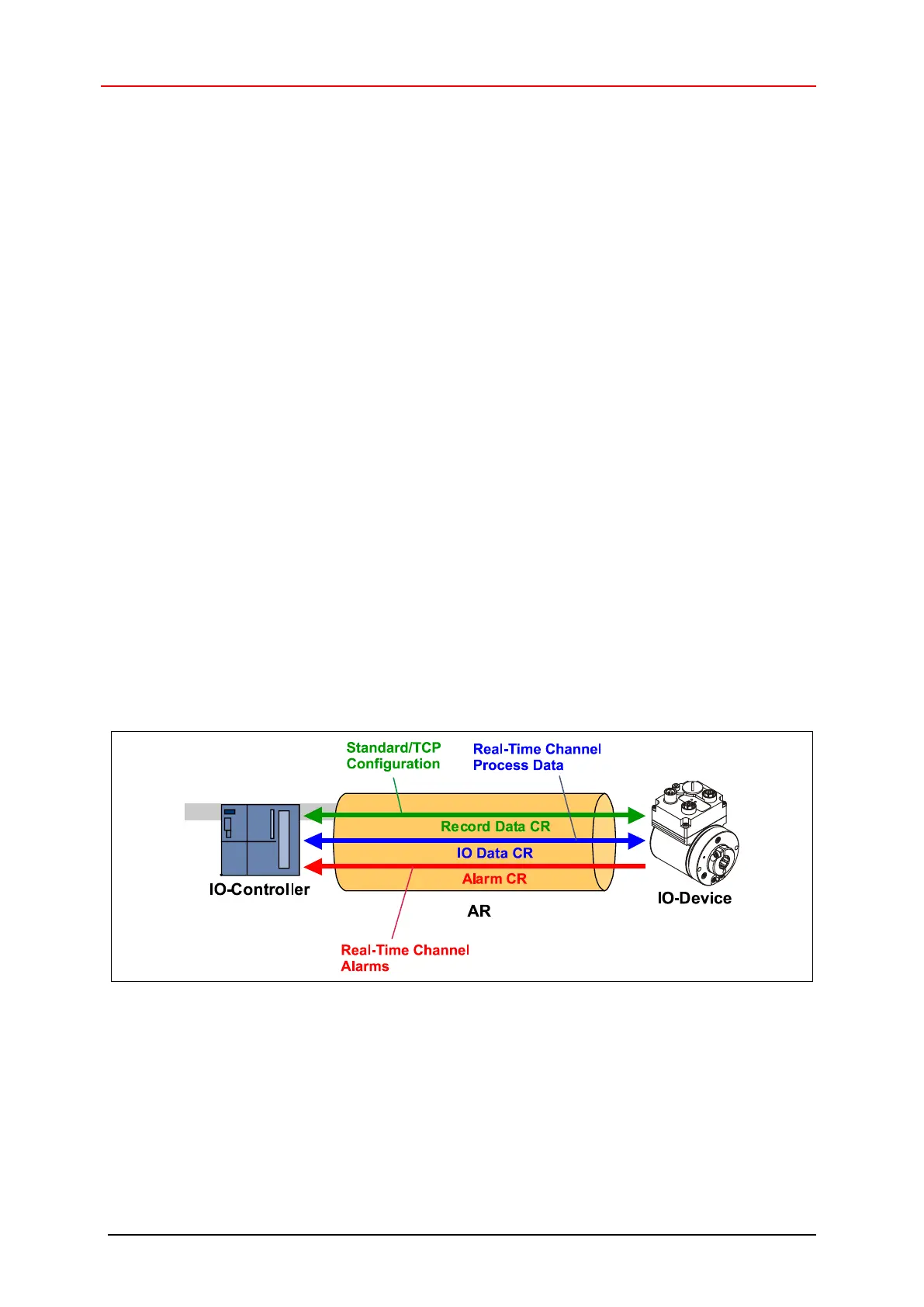

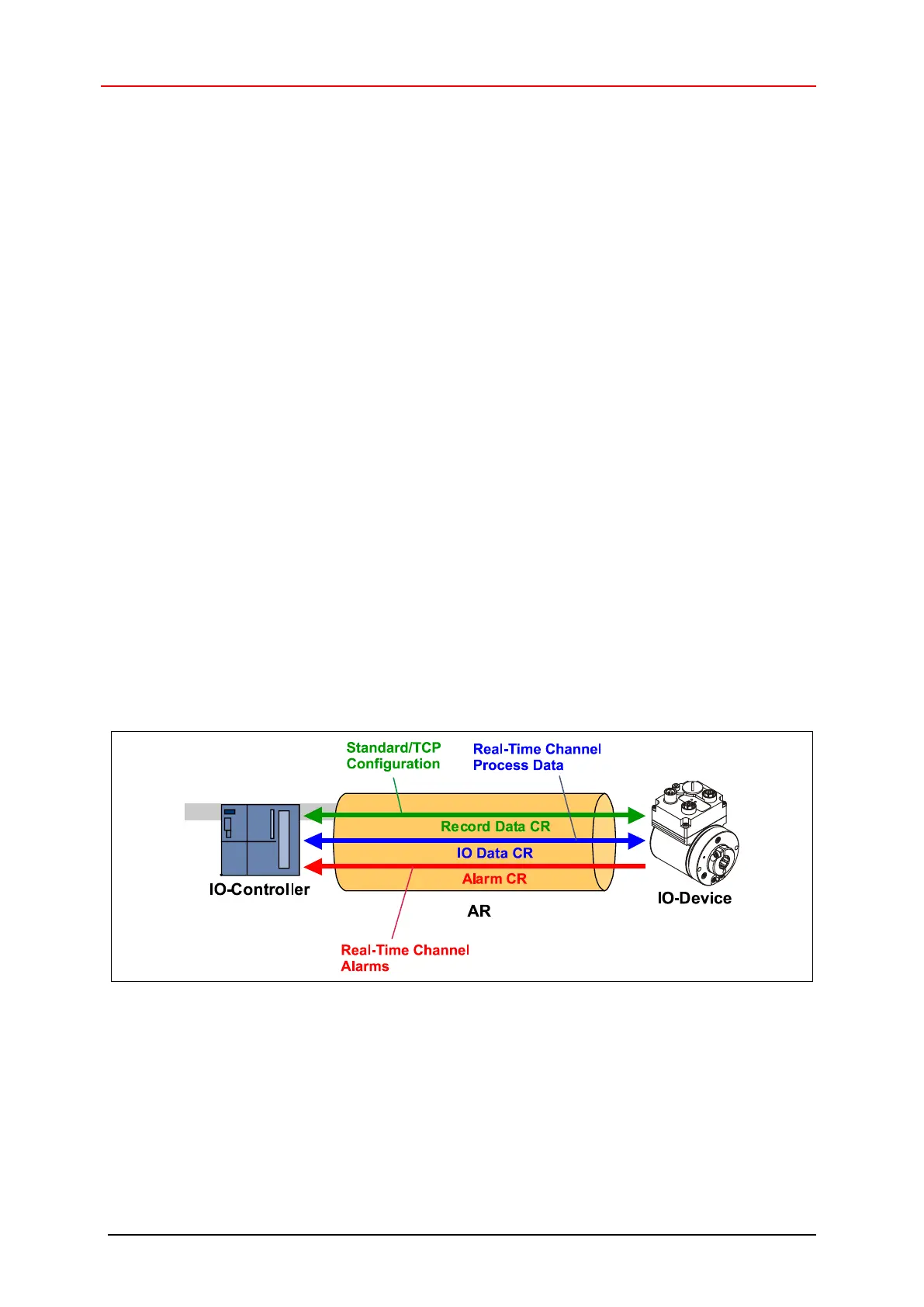

Figure 7: Device communication

AR:

Application relationship between IO controller and assigned IO devices.

CR:

Communication relationships for configuration, process data and alarms. One or more IO-CRs can be

defined within an AR. Each IO-CR can consist of several slots and subslots.

Loading...

Loading...