6-8 System Setup and Diagnostics

Setting Servo Gains

Trio Motion Technology

Setting Servo Gains

The servo system controls the motor by constantly adjusting the voltage out-

put which gives a speed demand to the servo drive. The speed demand is

worked out by looking at the measured position of the axis from the encoder

comparing it with the demand position generated by the Motion Coordinator.

The demand position is constantly being changed by the Motion Coordinator

during a move. The difference between the demand position (Where you want

the motor to be) and the measured position (Where it actually is) is called the

following error.

The controller checks the following error typically 1000 times per second and

updates the voltage output according to the “servo function”. The Motion

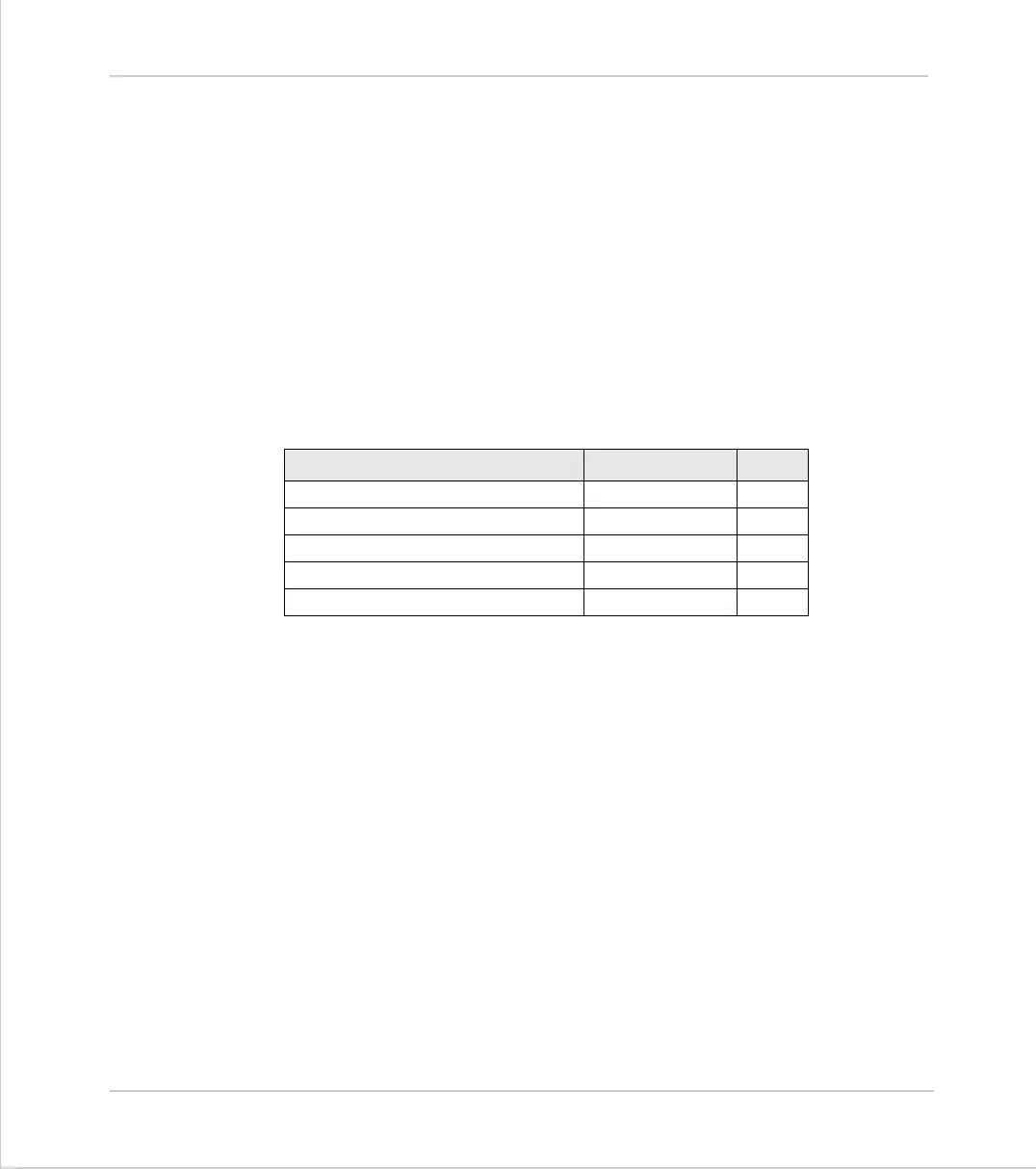

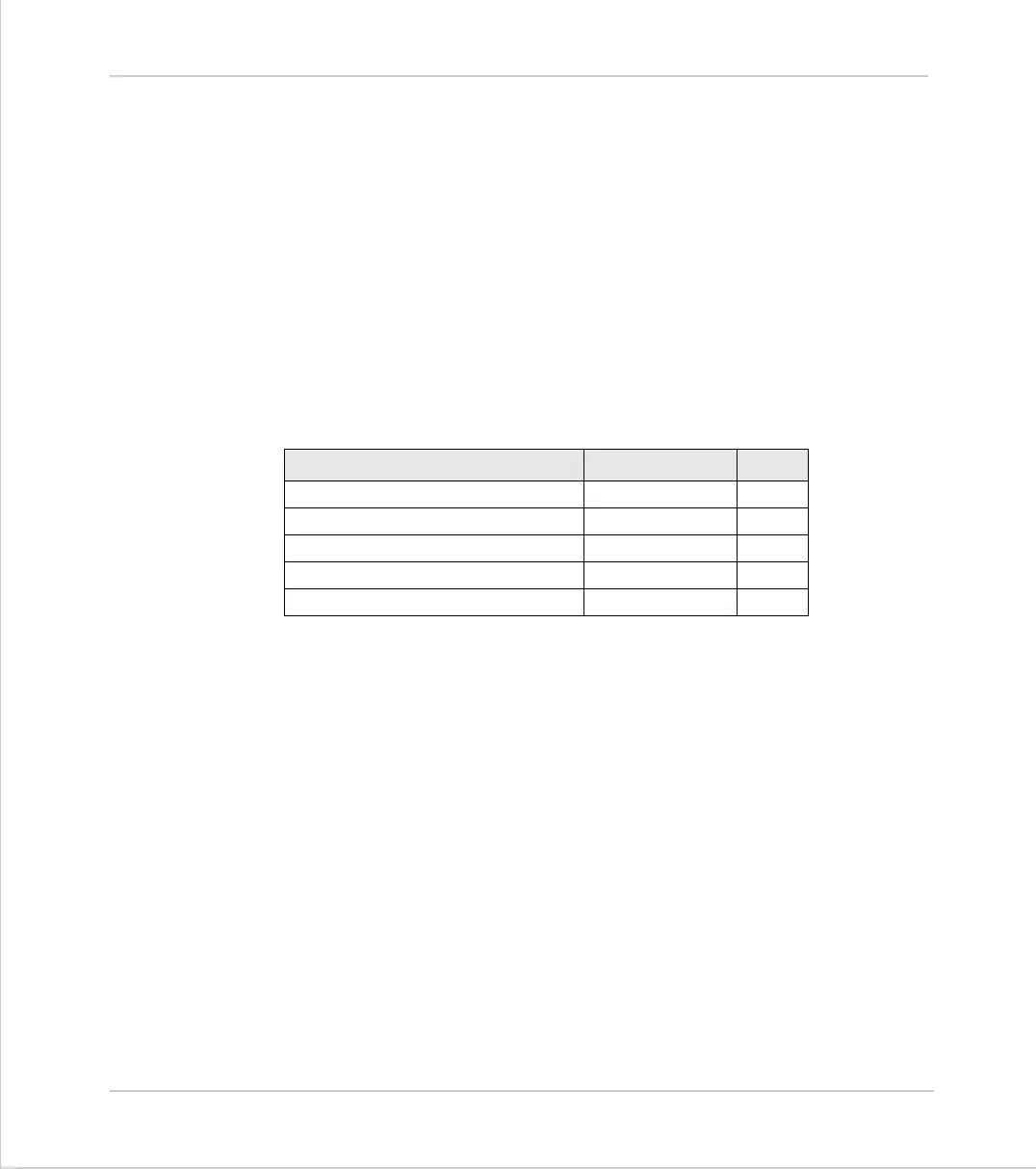

Coordinator has 5 gain values which control how the servo function generates

the voltage output from the following error.

Default Settings:

A simple test program can be used to generate movement to and fro for exam-

ination of the motion profile generated on an oscilloscope. The oscilloscope

should be connected to the tacho or velocity output from the servo drive.

Example:

PRINT "Enter Axis Number ":INPUT VR(0)

BASE(VR(0))

SPEED=20000

ACCEL=200000

DECEL=200000

loop:

MOVE(1000)

WAIT IDLE

WA(100)

MOVE(-1000)

WAIT IDLE

WA(100)

GOTO loop

Gain Parameter Name Value

Proportional Gain

P_GAIN

1.0

Integral Gain

I_GAIN

0.0

Derivative Gain

D_GAIN

0.0

Output Velocity Gain

OV_GAIN

0.0

Velocity Feedforward Gain

VFF_GAIN

0.0

Loading...

Loading...