Motion Coordinator Technical Reference Manual

Trio BASIC Commands 8-37

Motion and Axis Commands

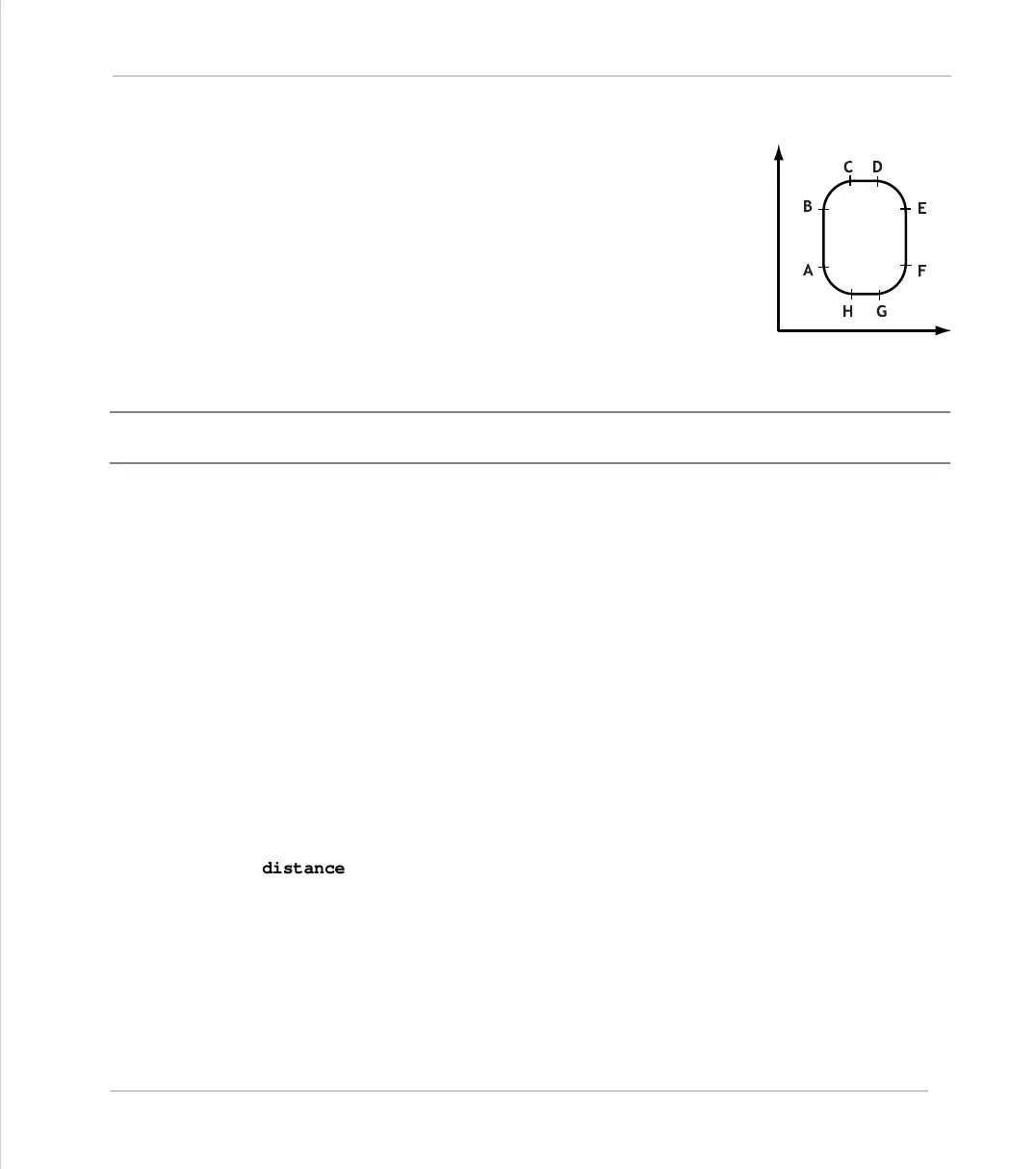

Example:

The command sequence to plot the letter ‘0’ might be:

MOVE(0,6)' move A -> B

MOVECIRC(3,3,3,0,1)' move B -> C

MOVE(2,0)' move C -> D

MOVECIRC(3,-3,0,-3,1)' move D -> E

MOVE(O,-6)' move E -> F

MOVECIRC(-3,-3,-3,0,1)' move F -> G

MOVE(-2,0)' move G -> H

MOVECIRC(-3,3,0,3,1)' move H -> A

MOVELINK

Syntax:

MOVELINK (distance, link dist, link acc, link dec, link axis[,

link options] [, link start]).

Type:

Motion Command.

Alternate Format:

ML()

Description:

The linked move command is designed for controlling movements such as:

• Synchronization to conveyors

•Flying shears

• Thread chasing, tapping etc.

•Coil winding

The motion consists of a linear movement with separately variable acceleration and

deceleration phases linked via a software gearbox to the MEASURED position (

MPOS

)

of another axis.

Parameters:

)

*

+,

-

.

/0

distance:

incremental distance in user units to be moved on the current

base axis, as a result of the measured movement on the

“input” axis which drives the move.

link dist:

positive incremental distance in user units which is required to

be measured on the “link” axis to result in the motion on the

base axis.

link acc:

positive incremental distance in user units on the input axis

over which the base axis accelerates.

Loading...

Loading...