Motion Coordinator Technical Reference Manual

Programming Examples 9-7

Example Programs

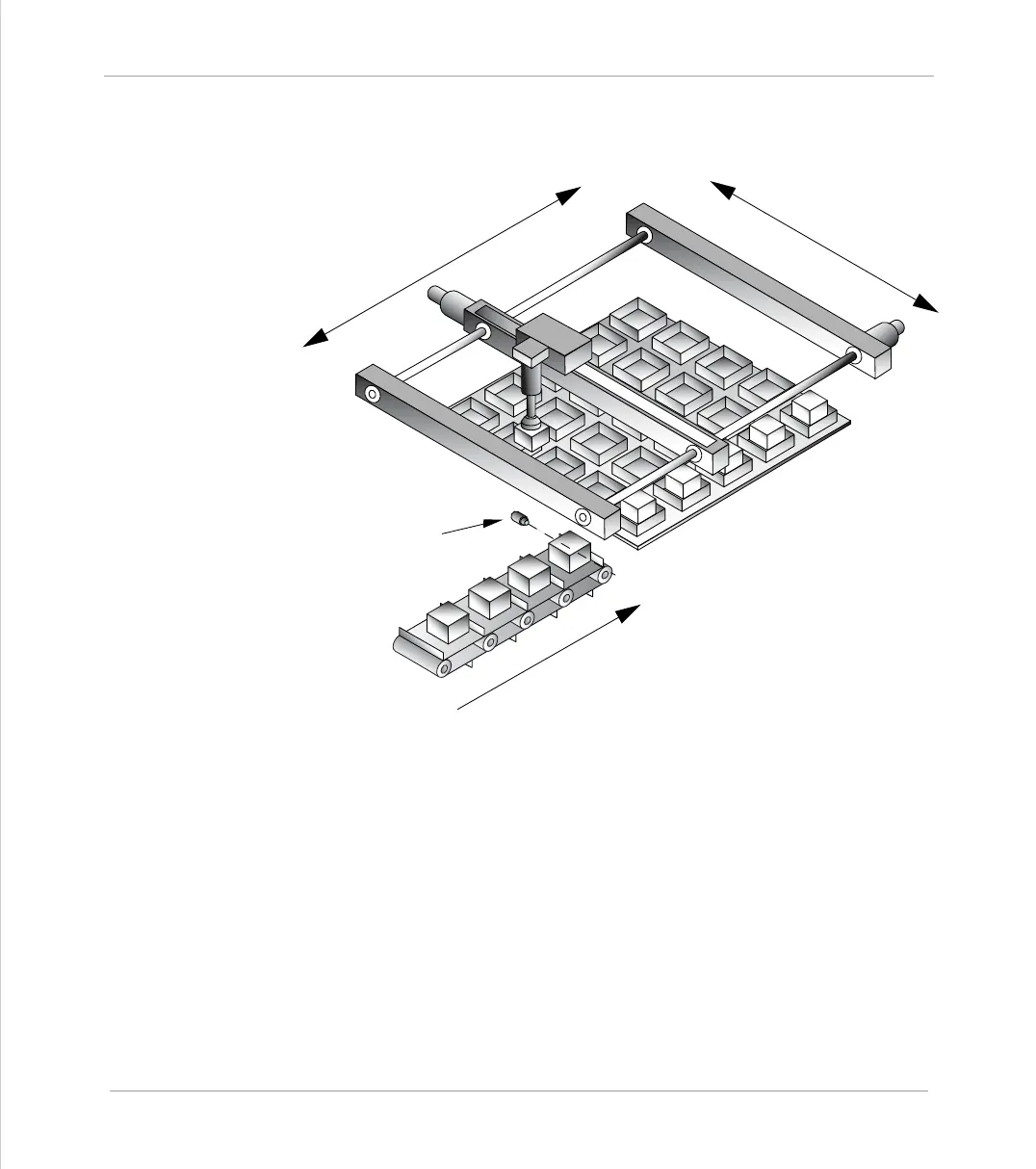

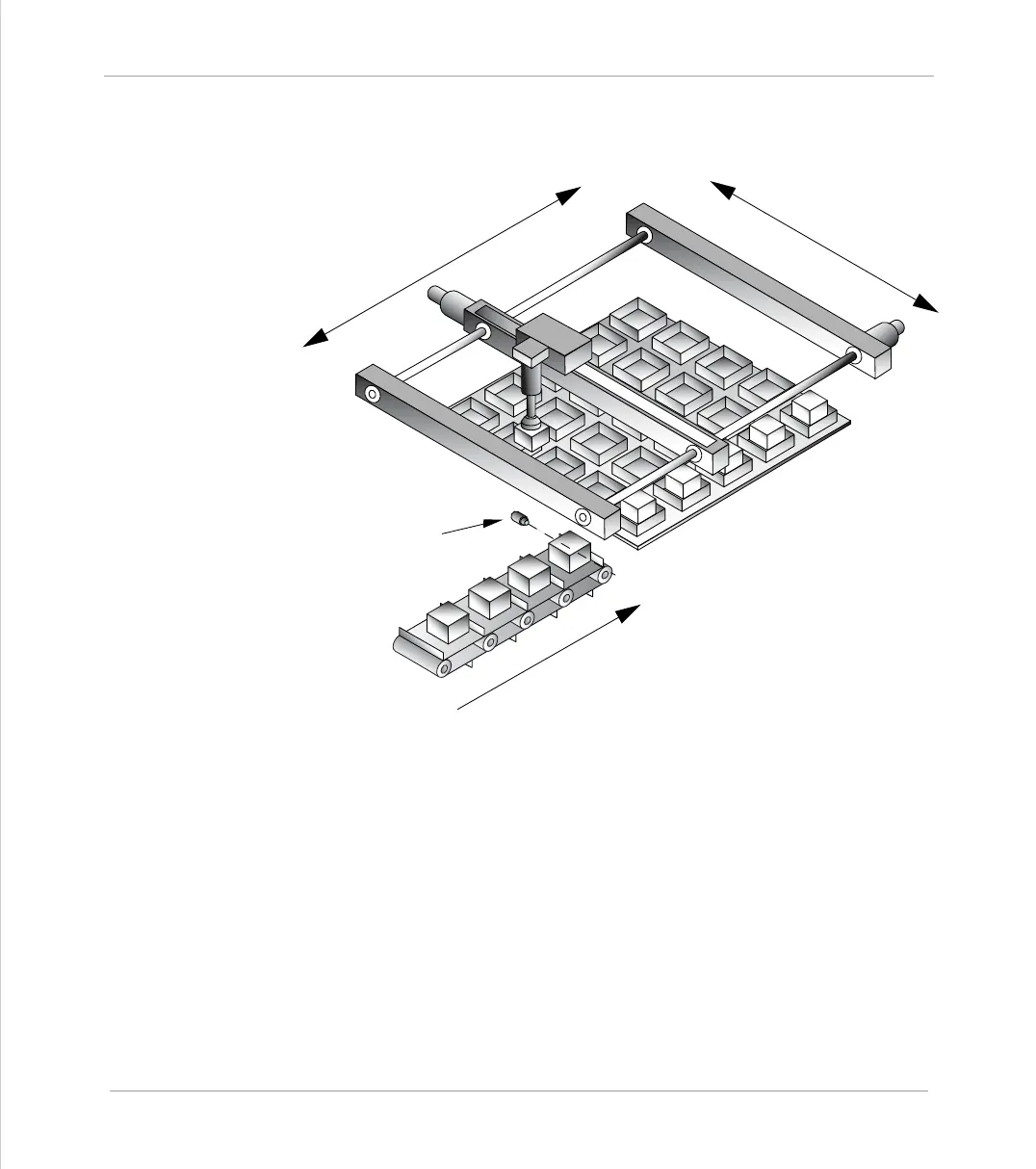

A vacuum operated pick-up mechanism collects objects from a conveyor and fills

each of the boxes in turn.

Additional Information:

Whist the palette size is fixed at the maximum size of 1.2m square, the program

should be flexible enough to allow for a user-defined number of boxes on the pal-

lette. The grid could contain up to 10 divisions in each direction and they may be

combined in any ratio, i.e. 2x4, 6x3, 1x10, 9x4 etc.

The illustration below shows a sample palette with a 6x6 grid of boxes. The num-

bers/arrows show the order in which the boxes are filled. Note that we step

through the rows (Y axis) in turn, filling each box (move along X axis) before mov-

ing onto the next row.

X

Y

Infeed

Conveyor

Product

Sensor

Loading...

Loading...