25

V01.0| 2017/04

TBPN-L1-FDIO1-2IOL - Standard IO-Link

3 IO-Link – Data Storage

Data storage enables a user to change an IO-Link device when maintenance is required without any

configuration or parameterization.

The IO-Link master, as well as the IO-link device, sto

re the device parameters. The data storage

mechanism serves for synchronizing these different data storage buffers.

In case of a device change, the master writes the stored device parameters to the new device. The

applicatio

n can be re-started without any further intervention using a configuration tool or similar.

In the IO-Link master, the data stor

age mode can be set using the parameter "data storage mode"

(see Parameters (page 14)).

data storage mode

00 = activated ( s. page 26)

01 = overwrite ( s. page 27)

10 = read in ( s. page 28)

11 = deactivated, clear ( s. page 28).

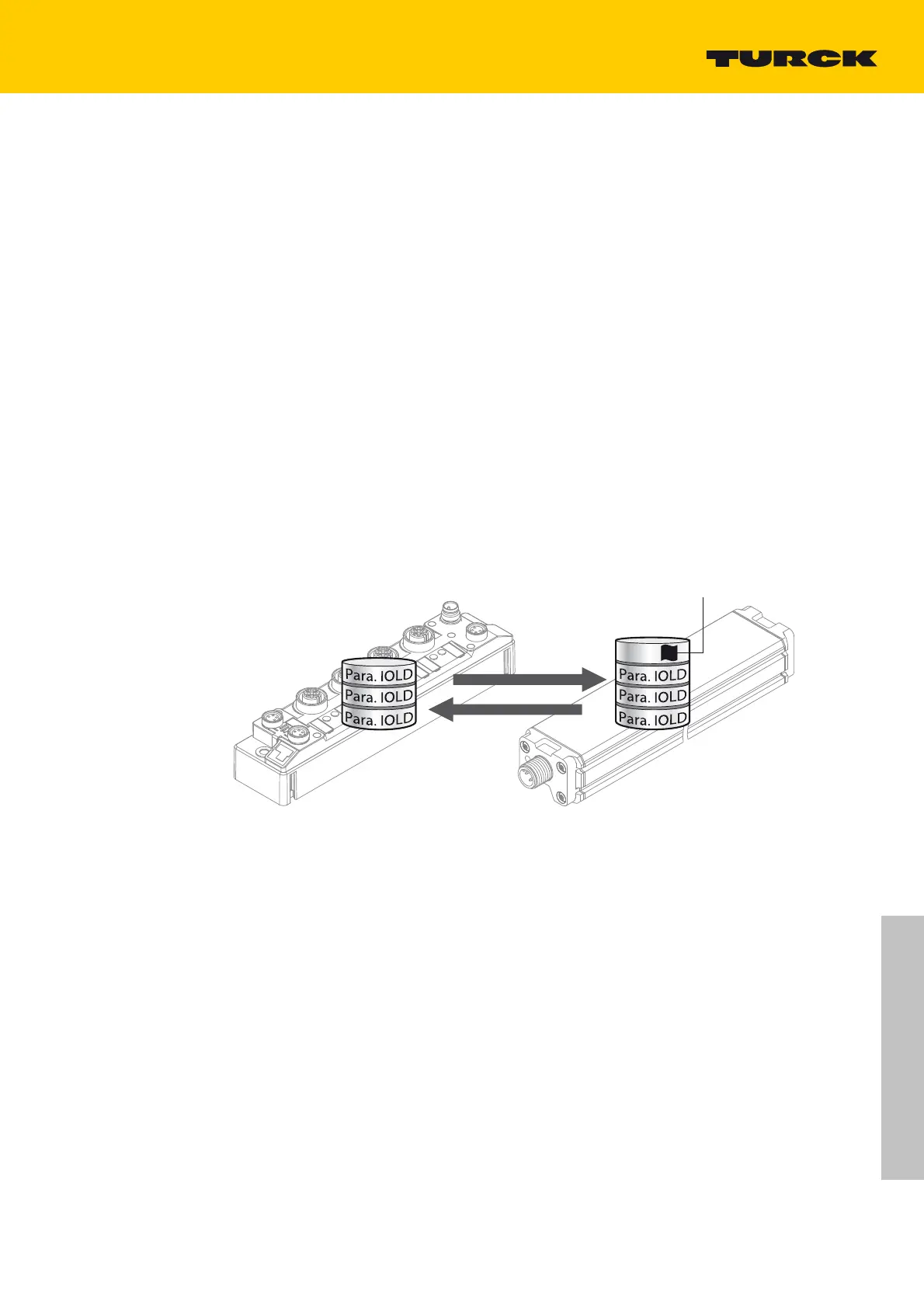

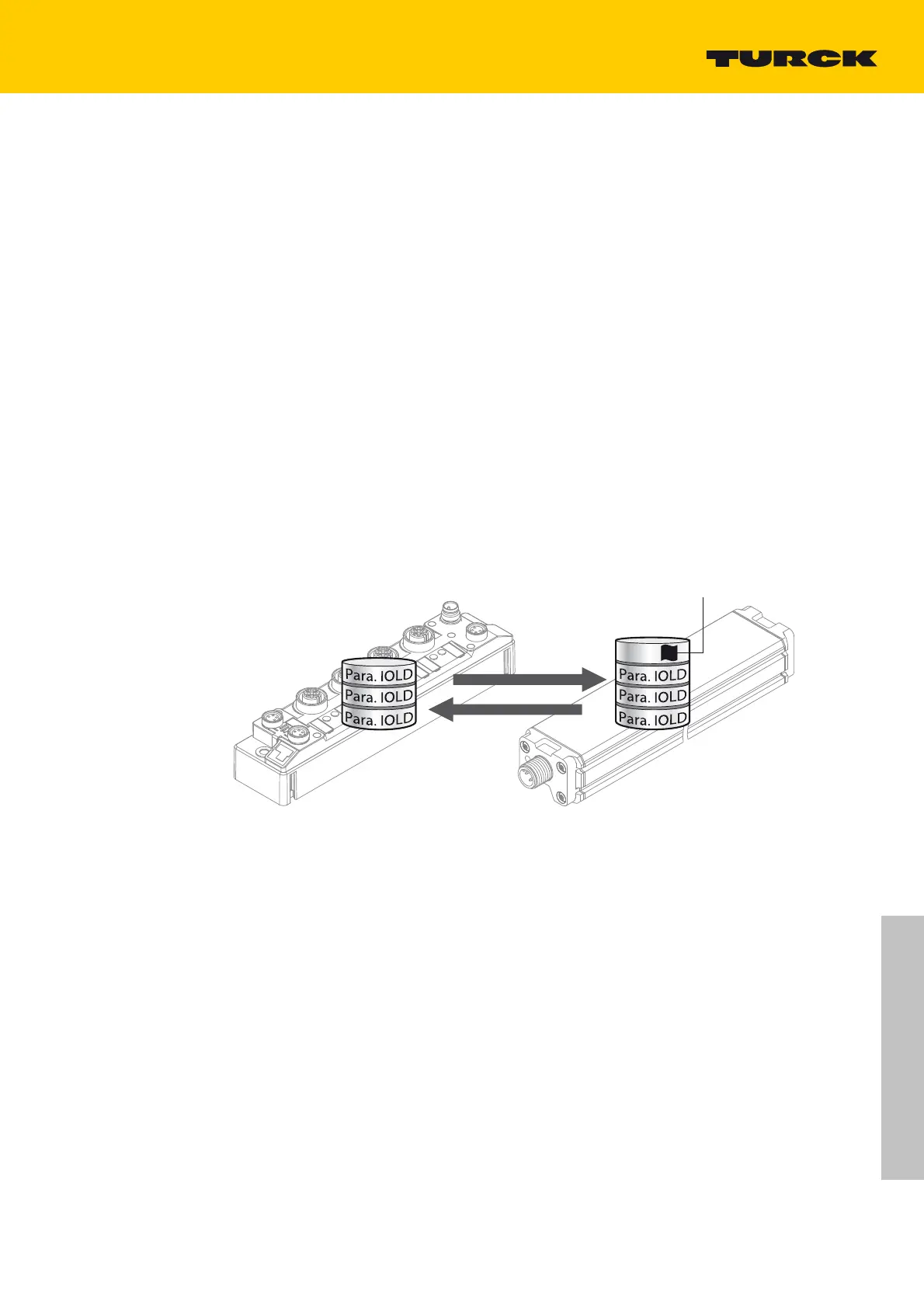

IO-Link-Master

(IOLM)

IO-Link-Device

(IOLD)

DS_UPLOAD_FLAG

Para. IOLD = parameter data of the IO-Link device

Fig. 3: General principle of the data storage mechanism

A change of parameters in the device is indica

ted by the status of the DS_UPLOAD_FLAG bit:

DS_UPLOAD_FLAG:

0 = no changes in the device's parameter

set

1 = changes in the device's parameter set (e.

g. via DTM, at the device, etc.)

Loading...

Loading...