No. Parameter Name Setting Range Default

C3-02 Slip Compensation Primary Delay Time 0 to 10000 ms 2000 ms

u

C4: Torque Compensation

The torque compensation function compensates for insufficient torque production at start-up or when a load is applied.

Note: Before making changes to the torque compensation gain make sure the motor parameters and V/f pattern are set properly.

n

C4-01: Torque Compensation Gain

Sets the gain for the torque compensation function.

No. Parameter Name Setting Range Default

C4-01 Torque Compensation Gain 0.00 to 2.50 1.00

The drive calculates the motor primary voltage loss using the output current and the terminal resistance value (E2-05) and

then adjusts the output voltage to compensate insufficient torque at start or when load is applied. The effect of this voltage

compensation can be increased or decreased using parameter C4-01.

Adjustment

Although

this parameter rarely needs to be adjusted, small changes in increments of 0.05 may help in the following situations:

• Increase this setting when using a long motor cable.

• Decrease this setting when motor oscillation occurs.

Adjust C4-01 so that the output current does not exceed the drive rated current.

u

C6: Carrier Frequency

n

C6-01: Drive Duty Selection

The

drive has two different duty modes from which to select based on the load characteristics. The drive rated current, overload

capacity, and carrier frequency will change depending upon the duty mode selection. Use parameter C6-01 to select Heavy

Duty (HD) or Normal Duty (ND) for the application. Refer to Specifications on page 179 for details about the rated current.

No. Parameter Name Setting Range Default

C6-01 Drive Duty Selection 0 or 1 1

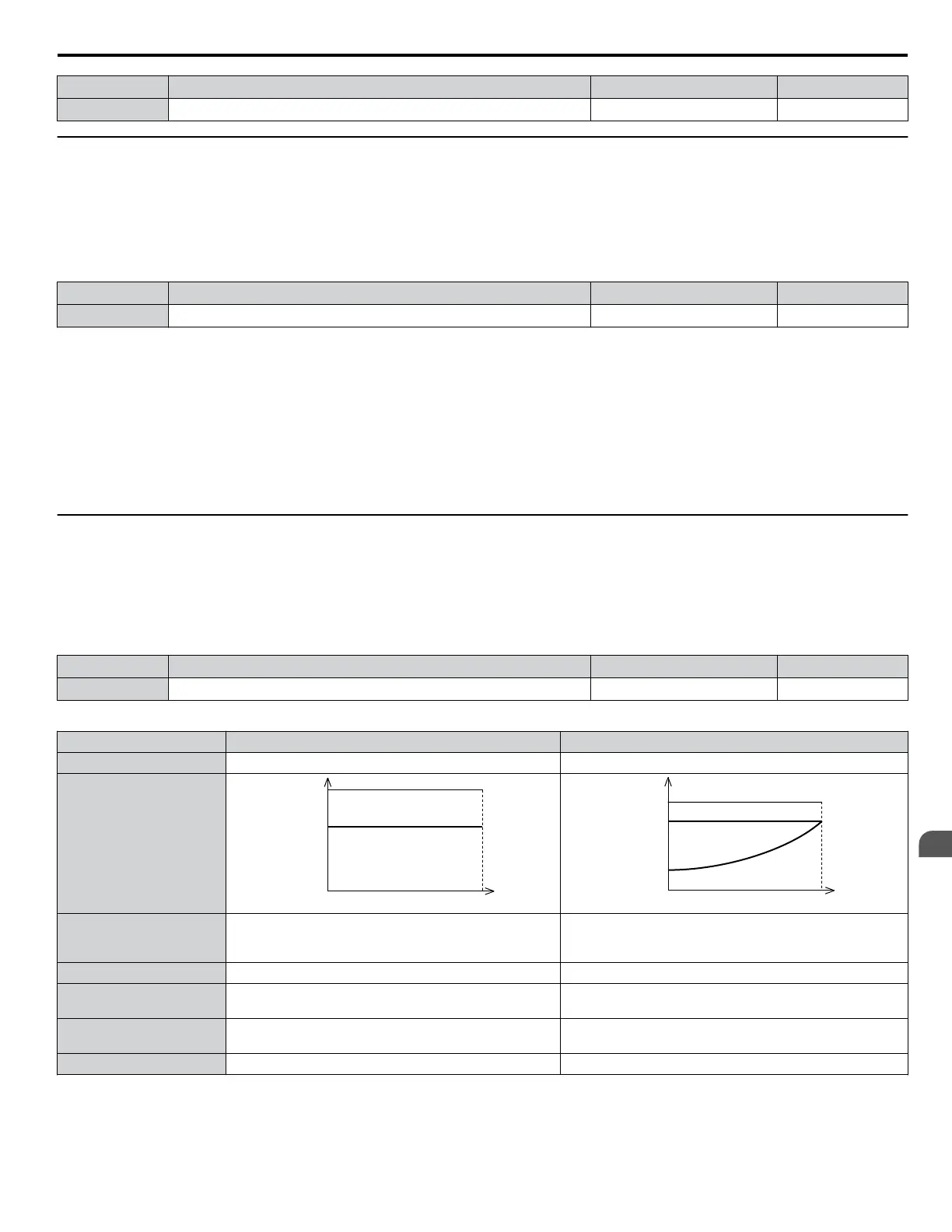

Table 5.6 Differences between Heavy and Normal Duty

Mode Heavy Duty Rating (HD) Normal Duty Rating (ND)

C6-01 0 1

Characteristics

100 %

100 %

0 Motor Speed

Rated Load

Overload

150 %

Motor Speed

0

100 %

100 %

120 %

Rated Load

Overload

Application

Use Heavy Duty Rating for applications requiring a high

overload tolerance with constant load torque. Such

applications include extruders and conveyors.

Use Normal Duty Rating for applications in which the torque

requirements drop along with the speed. Examples include

fans

or pumps where a high overload tolerance is not required.

Over load capability (oL2) 150% of drive rated Heavy Duty current for 60 s 120% of drive rated Normal Duty current for 60 s

L3-02 Stall Prevention

during Acceleration

150% 120%

L3-06 Stall Prevention

during Run

150% 120%

Default Carrier Frequency 8/10 kHz 2 kHz Swing PWM

Note:

By changing the Duty Mode the drive maximum applicable motor power changes and the E2-ooparameters are automatically set to

appropriate values.

5.3 C: Tuning

YASKAWA ELECTRIC SIEP C710606 31B YASKAWA AC Drive – J1000 Technical Manual

87

5

Parameter Details

http://nicontrols.com

Loading...

Loading...