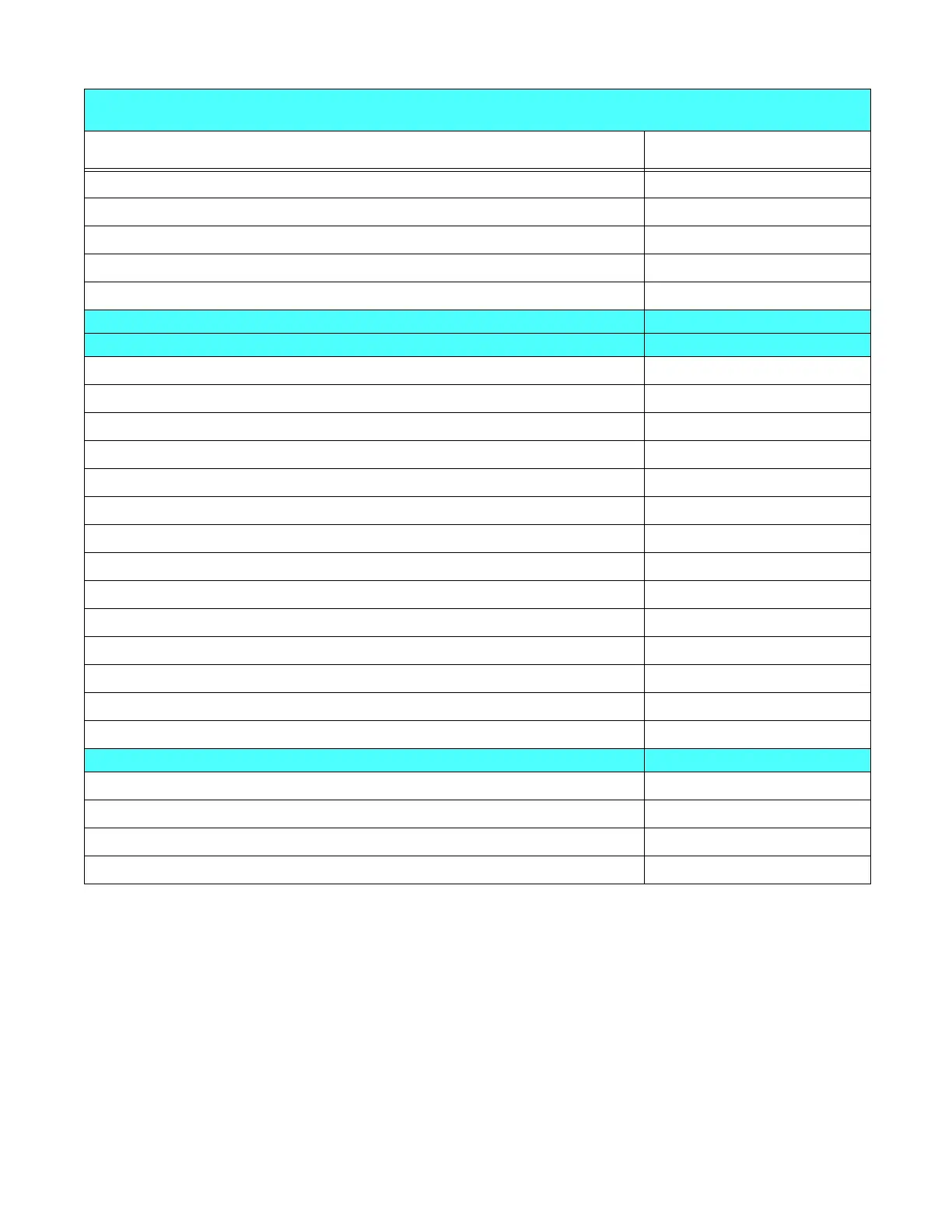

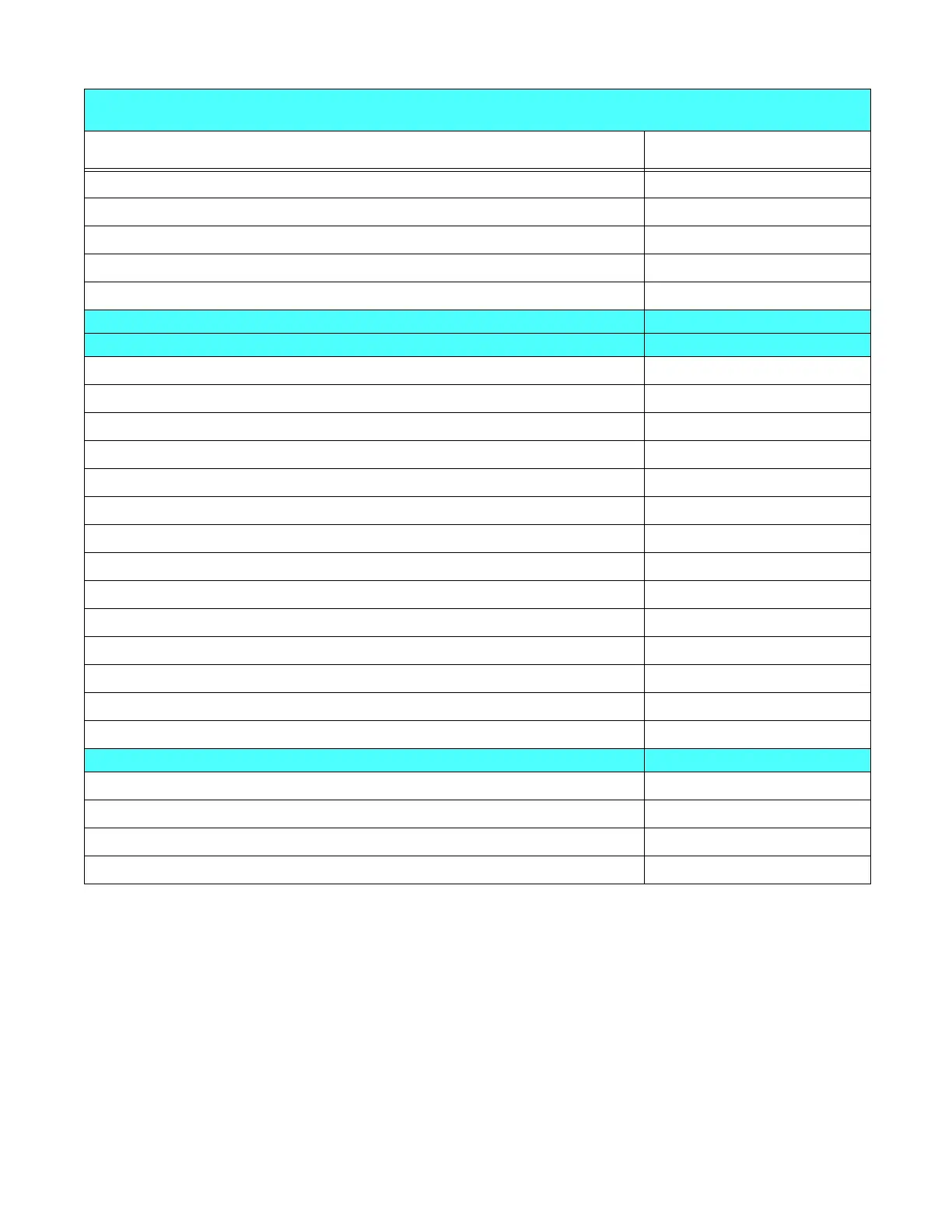

8-2

P129394-176 Operator Manual Routine Maintenance

2.10 Sight Glass & Seal replace

2 x per year

2.11 Safety valve replace

2.12 Check valve replace

2.13 Steam outlet valve rebuild

2.14 Feed water valve rebuild

3.0 Calibration – Temperature & Pressure - Annual 1 x per year

4.0 Routine Maintenance 2 x per year unless noted

4.1 Check chamber level sensor

4.2 Verify door operation

STEAM GENERATOR (If applicable)

4 x per year (4.3 - 4.12)

4.3 Check appearance for leaks and damage

4.4 Check sight glass for leaks or cracks

4.5 Check relays and contactors for arc damage or wear

4.6 Check heater wiring for cracking or damage

4.7 Flush or blow down unit per P764332-324/325

4.8 Check strainer

4.9 Check pump motor clamp

4.10 Remove and clean conductivity/float probes

4.11 Examine probe baffle tube for wear (if equipped)

4.12 De-scale per procedure P764326-931

4.13 Re-install panels, clean area and test

5.0 Final Test/Administrative

2 x per year (4 x w/generator)

5.1 Run test cycle (Vacuum Leak Test)

5.2 Check for leaks

5.3 Check Display for proper operation

5.4 Clean area and equipment as needed

Table 8-1. Preventive Maintenance

Periodic Maintenance Schedule for AMSCO C Series Small Steam Sterilizer

Service Required

Minimum Inspection

Frequency

Loading...

Loading...