8-1

Routine Maintenance Operator Manual P129394-176

8.1 Preventive

Maintenance Schedule

Maintenance procedures should be performed regularly at the

intervals indicated using the maintenance schedule below as a

guide. Local conditions (water quality, usage, etc.) may require more

frequent maintenance than indicated.

Important: Follow all safety procedures including Lock out/Tag out.

Inspection Frequency: The AMSCO

®

C Series Small Steam

Sterilizer must be inspected twice each year. Operator inspections

must be made on a daily or weekly basis as indicated in S

ECTION 8.2,

D

AILY MAINTENANCE PROCEDURES and SECTION 8.3, WEEKLY

MAINTENANCE PROCEDURE: FLUSH CHAMBER DRAIN.

WARNING – PERSONAL INJURY HAZARD and/or EQUIPMENT DAMAGE HAZARD: Regularly

scheduled preventive maintenance is required for safe and reliable operation of this equipment.

Contact your STERIS Service Representative to schedule preventive maintenance.

WARNING – PERSONAL INJURY HAZARD and/or EQUIPMENT DAMAGE HAZARD: The

performance of the 510k cleared AMSCO C Series Sterilizer is validated as a system including

components defined by STERIS in the Operator Manual and Service Manual for the AMSCO C

Series Sterilizer. Substitution of unauthorized components can potentially lead to personal injury,

damage or premature failure of the product and result in a unit configuration that is inconsistent

with the validated, FDA cleared product. STERIS' warranty is void if components are used that are

not approved. DO NOT USE components that are not validated as part of the AMSCO C Series

Sterilizer.

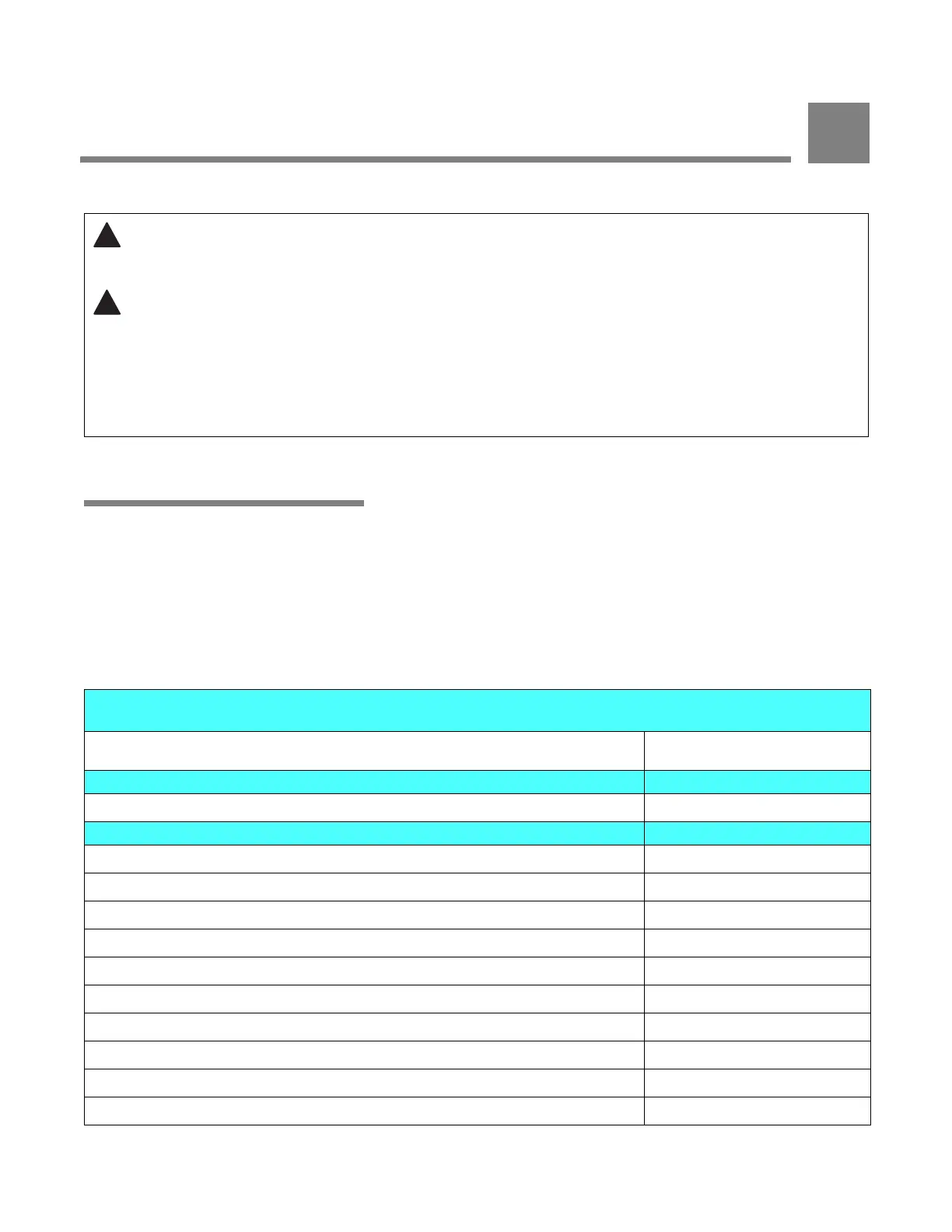

Table 8-1. Preventive Maintenance

Periodic Maintenance Schedule for AMSCO C Series Small Steam Sterilizer

Service Required

Minimum Inspection

Frequency

1.0 Administrative

2 x per year (4 x w/generator)

1.1 Discuss equipment operation with operator.

2.0 Restorative – Rebuilds and replacements

1 x per year unless noted

2.1 Rebuild steam manifold

2.2 Rebuild water manifold

2.3 Rebuild Jacket Trap

2.4 Replace safety valve

2.5 Replace air filter

2.6 Rebuild Pressure Regulator (PRV)

2.7 Replace jacket trap check valve (CK3)

2.8 Rebuild exhaust manifold

2.9 Replace check valve (CK14)

STEAM GENERATOR (If applicable)

ROUTINE MAINTENANCE

8

Loading...

Loading...