8-8

P129394-176 Operator Manual Routine Maintenance

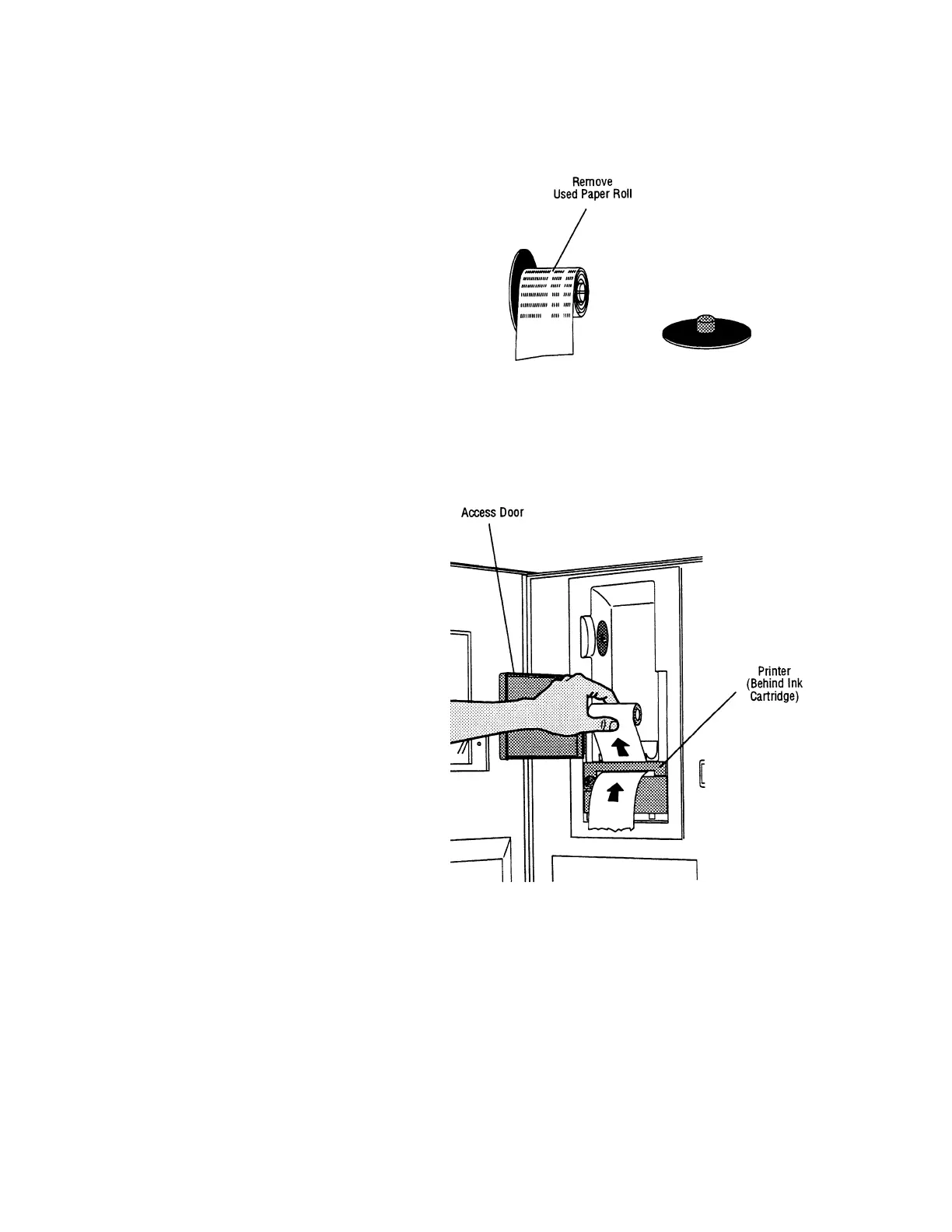

3. Pull off right end of spool and remove used paper roll from

spindle.

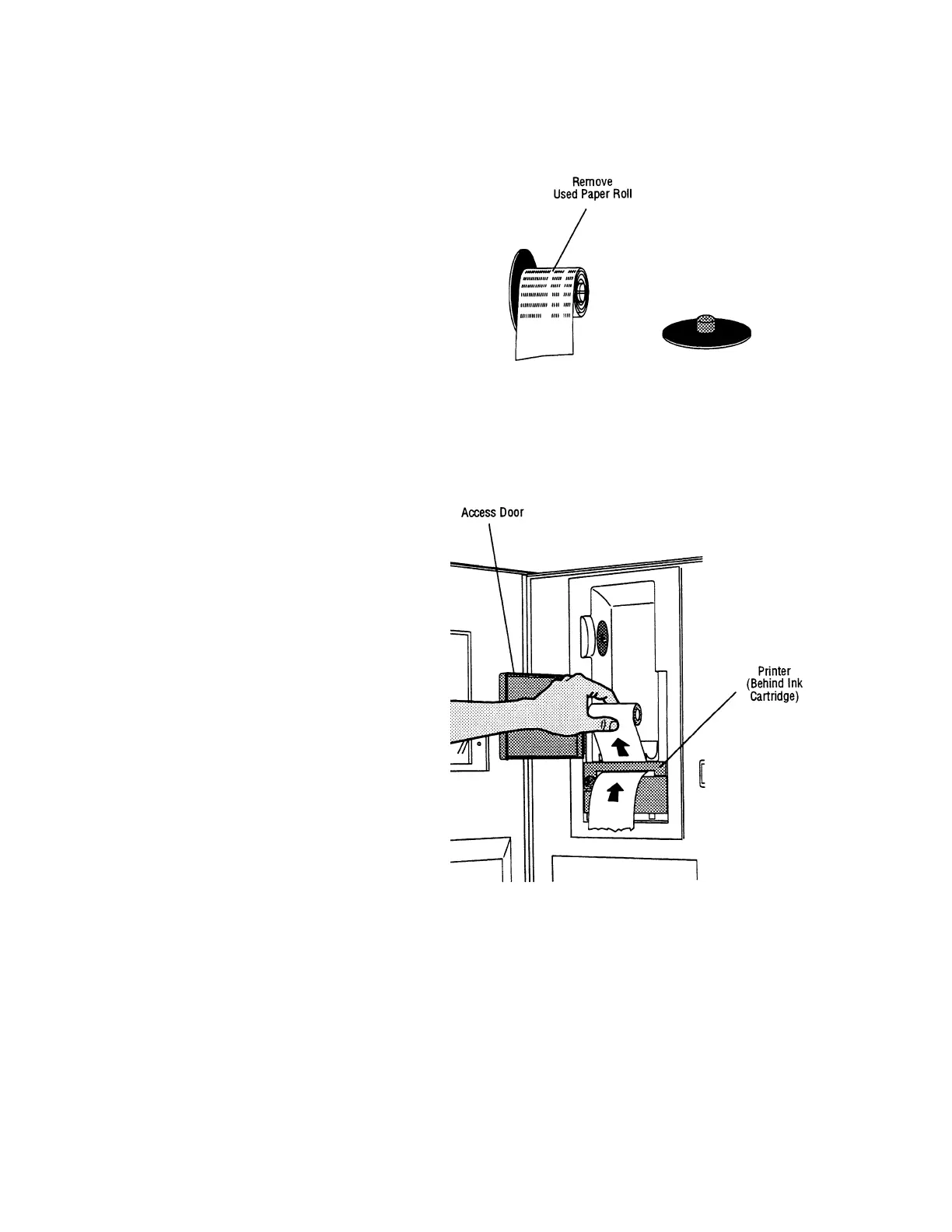

4. Open access door and remove previous paper roll, gently

pulling any remaining paper up and out of printer.

Figure 8-4. Remove Paper From Spool

Figure 8-5. Remove Remaining Previous Paper

Loading...

Loading...