10-5

Service Procedures Operator Manual P129394-176

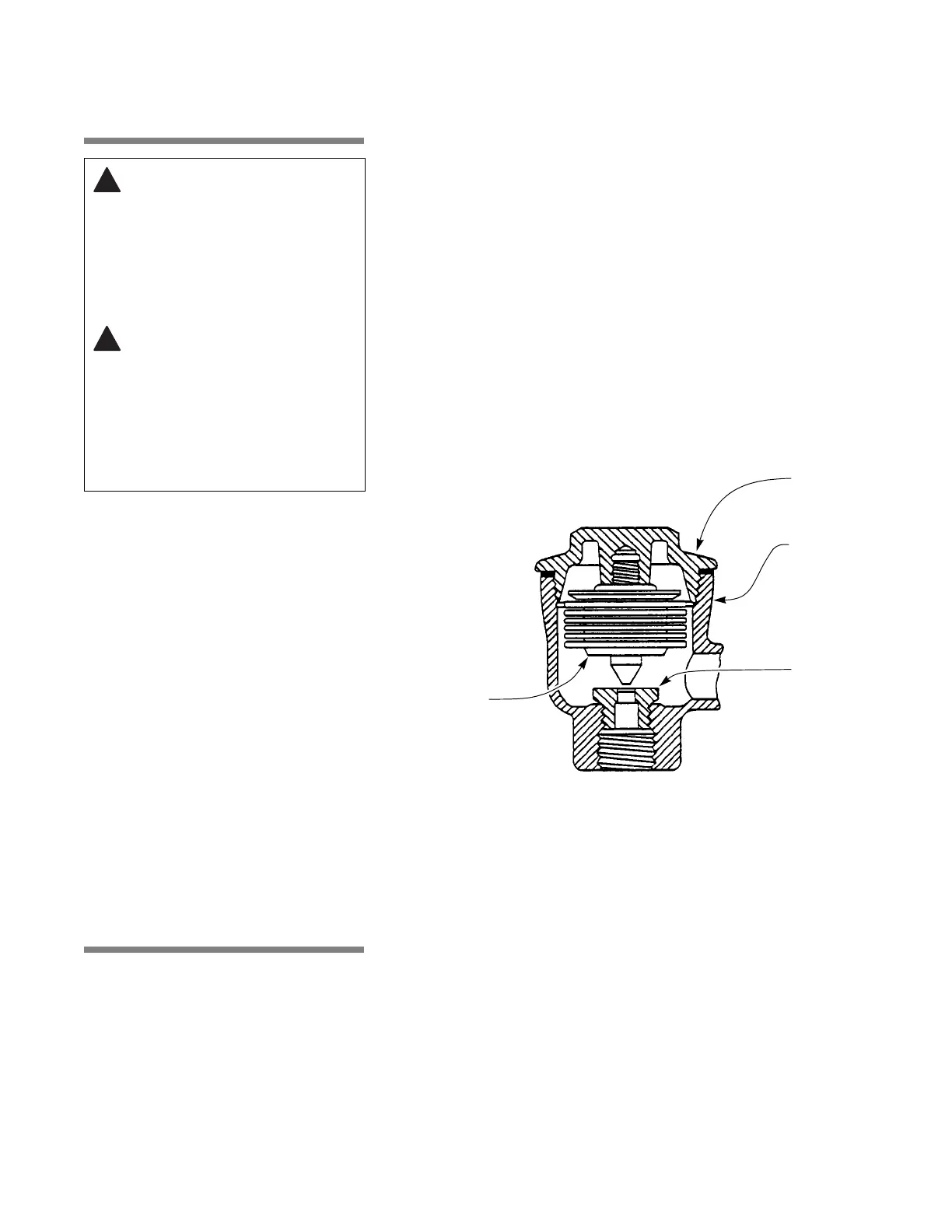

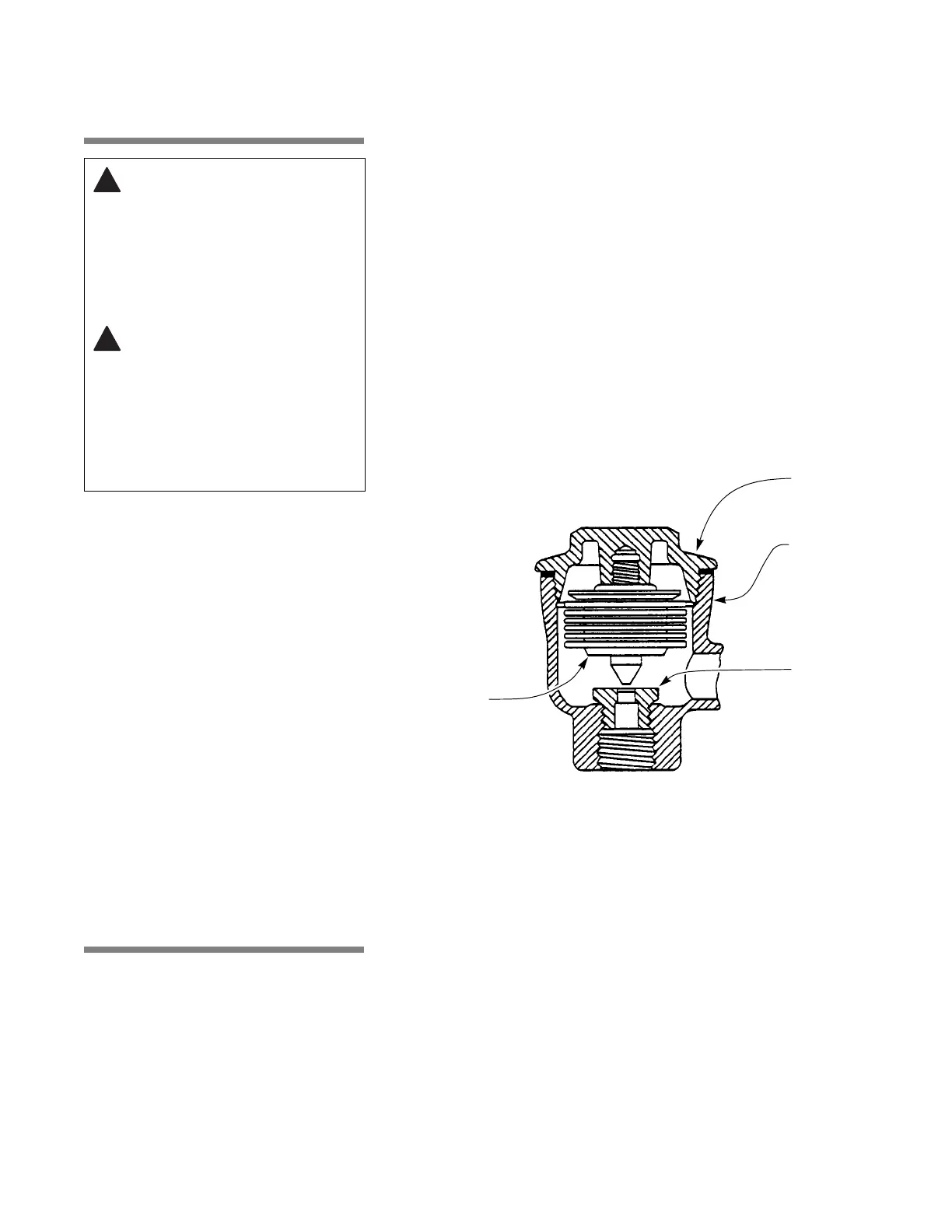

10.5 Steam Trap

Replacement

Refer to Figure 10-4.

Disassembly

1. Using a suitable wrench, unscrew and remove the cap and

bellows assembly.

2. Remove seat from body using a hex socket wrench.

3. Wipe out bowl taking care that loose material does not enter the

piping.

Reassembly

1. Screw new seat in firmly. (Use a socket head wrench to tighten.)

NOTE: Seat and bellows are a lapped pair.

2. Install new bellows.

3. Replace cap and attached bellows assembly, using a new

gasket.

4. Check for leaks.

Figure 10-4. Steam Trap

10.6 Clean or Replace

Piping Check Valves

Repair of check valve is limited to cleaning of valve seats when

foreign matter causes improper operation. When a valve becomes

defective, the entire valve must be replaced, unless the check valve

has a field repair kit. Kit consists of new seals and springs. Please

contact STERIS Corporation for correct check valve part number.

WARNING – BURN HAZARD:

• Allow sterilizer and

accessories to cool to room

temperature before performing

any cleaning.

• Jacket pressure must be at

0 psig before beginning work

on the steam trap.

CAUTION – POSSIBLE

EQUIPMENT DMAMGE

HAZARD: Allow thermostatic

traps to cool down to room

temperature before removing

cover. Since there is nothing

to limit expansion, the bellows

may rupture or fatigue if trap

is opened while hot.

Loading...

Loading...