CHAPTER 5 – Controls and use

Chap. 5

- 25/48 -

STEP ACTION DESCRIPTION

4

Activating the

command

• If a person is in danger, press the emergency stop pushbutton on any control

panel.

• The emergency stop is a safety stop and has priority over all other controls; it

is not synchronized with the forward feed of the machined product, which may

therefore become jammed in one or more points in the machine subsequent

to the stop.

5.5.2 Stop and re-start procedure after working stop - STOP

In the event of a sudden machine stop, be it intentional or accidental, correct function re-start depends

on how the machine has been stopped.

Proceed as described following.

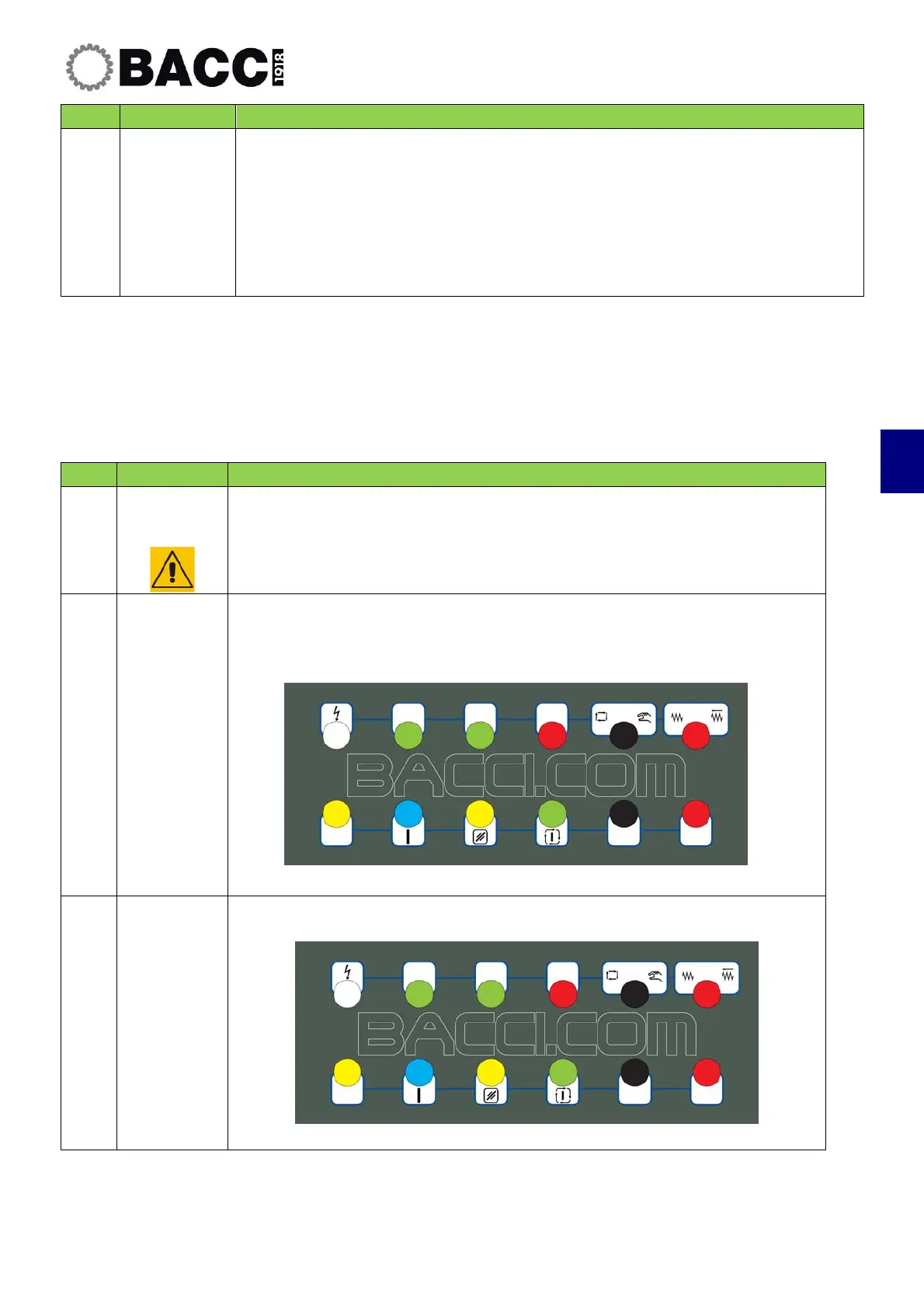

STEP ACTION DESCRIPTION

1

Press the

STOP

pushbutton

Before using the machine, all persons involved must be familiar with the

location and use of all the STOP pushbuttons on the machine shown in the

pictures.

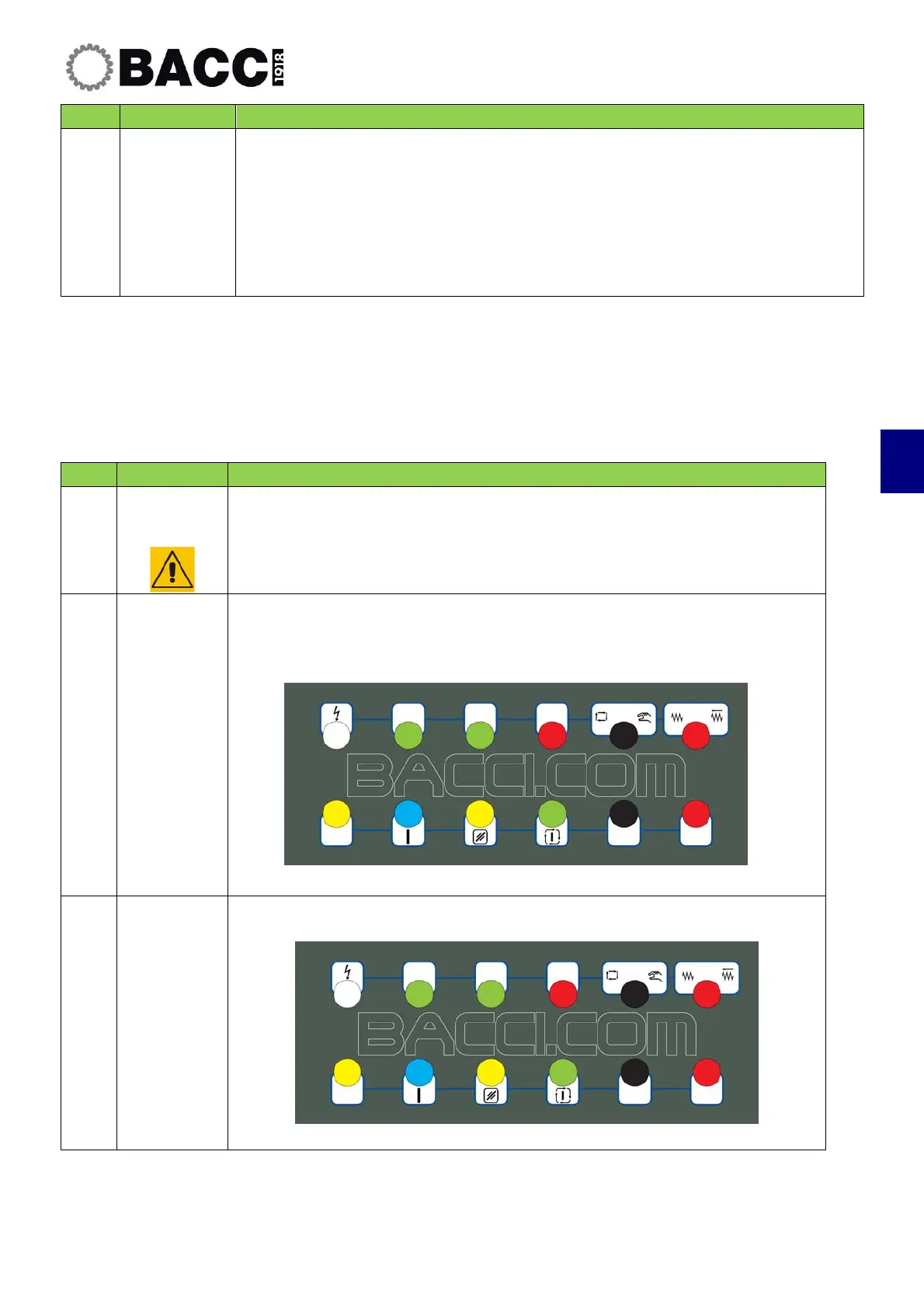

2

Re-start

procedure

To re-start the machine after a machine STOP:

• Remove the cause for the machine stop

• Press the "Reset" key (9).

3

Start cycle

Press the “Start automatic cycle” pushbutton (10)

Loading...

Loading...