TWIN – Use and maintenance instruction manual

Chap. 3

- 16/28 -

3.7.8 Depression table (OPTIONAL)

Made up of aluminum, variable size, 50 mm grid and equipped with lids and threaded holes, it can

be mounted directly on the TGV or its supports, to facilitate locking of flat-base pieces, and for

machining the upper side of the workpiece.

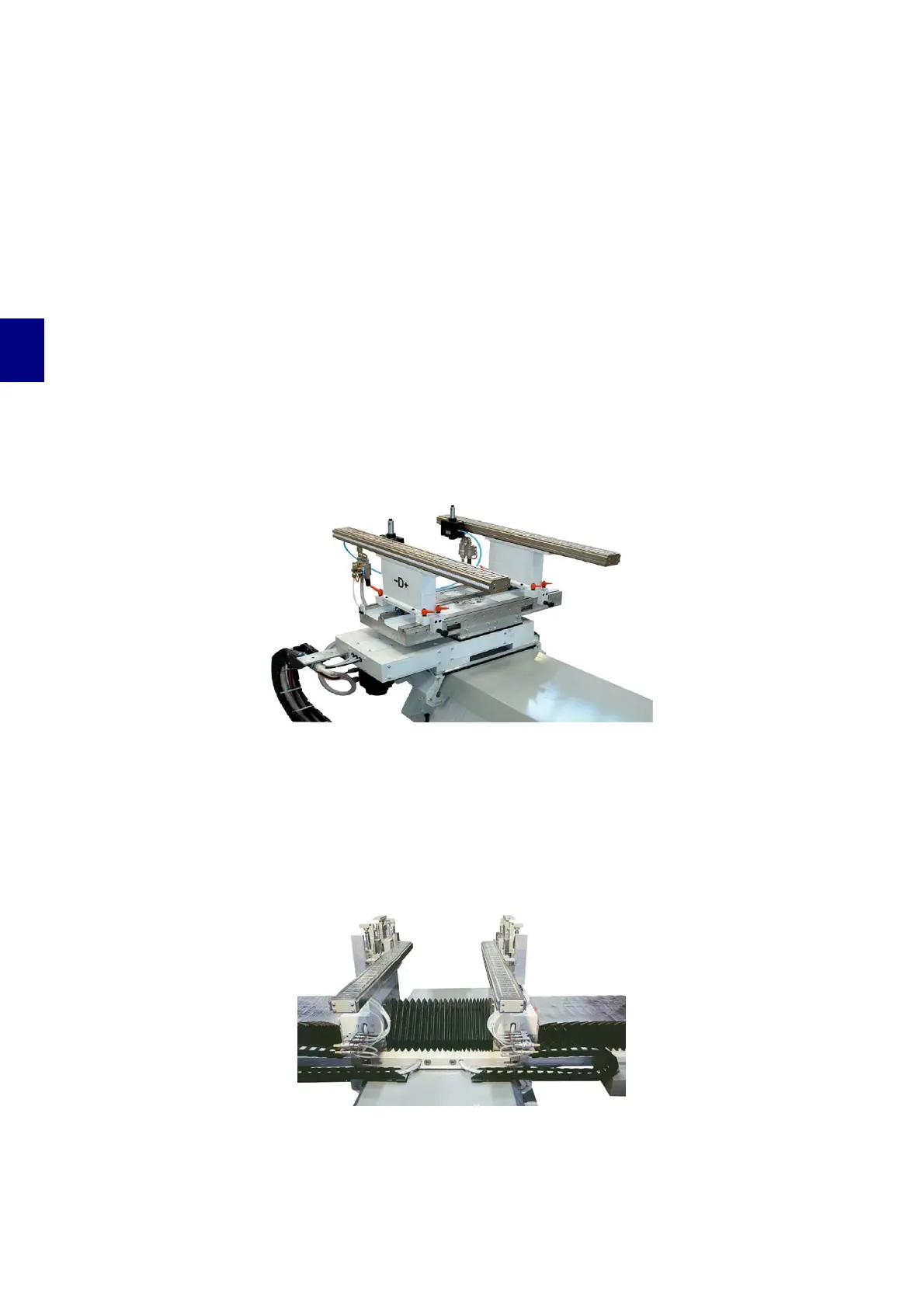

3.7.9 “TGV-TRC” - Rotating Variable Geometry Tables (OPTIONAL)

The patented “TGV” variable geometry tables described above may be mounted on continuously

rotating aluminum boards, around a vertical interpolated axis (additional “A” interpolated axis). The

max center distance of the shelves is 1170 mm and their length is 1130 mm.

Due to the rotation, all the 4 sides of the table may be turned toward the machining head;

therefore, it is not only possible the complete machining of the 5 sides of a workpiece, but also the

positioning of more details on the same counterprofile, hence reducing the setup time.

The rotating table also allows to increase the contouring dimensional capacity up to 1800 mm.

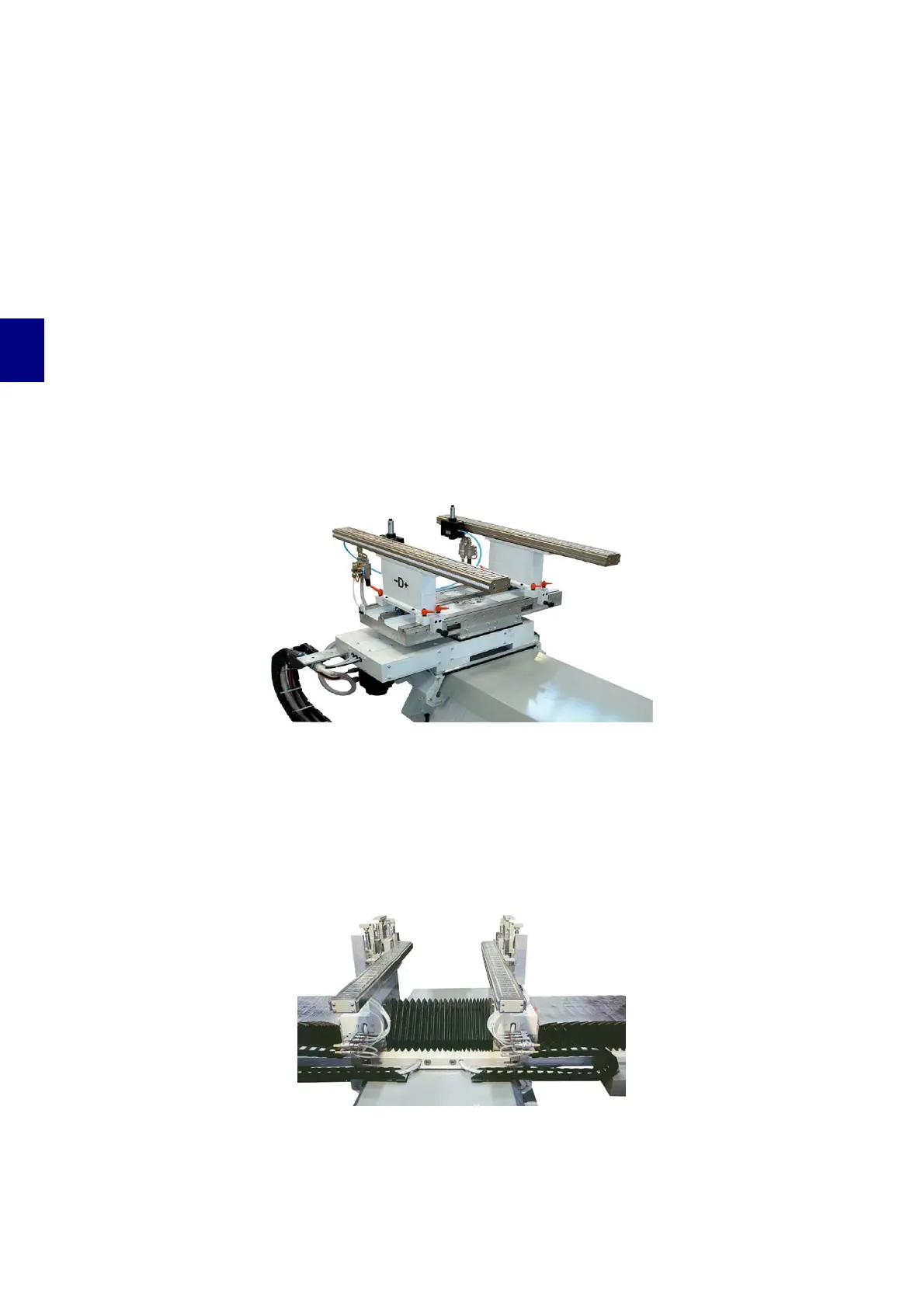

3.7.10 “TGV-CN” - Numerically Controlled Variable Geometry Tables

(OPTIONAL)

In this kind of table, the center distance of the shelves is interpolated and numerically controlled

along the “X” direction. This allows coaxial, mirrored, simultaneous machining, therefore halving

the processing time. The two shelves can be positioned by the numerical controller at a maximum

opening of 1185 mm, and remain fixed during machining.

Loading...

Loading...