connected to the VLT

®

AQUA Drive is also controlled to

provide a continuous range of system output.

Designated use

The cascade controller options are designed for pump

applications; however, it is also possible to use cascade

controllers in any application requiring multiple motors

congured in parallel.

Operating principle

The cascade controller software runs from a single

adjustable frequency drive with the cascade controller

option. It controls a set of pumps, each controlled by an

adjustable frequency drive or connected to a contactor or

a soft starter.

Additional adjustable frequency drives in the system (slave

adjustable frequency drives) do not need any cascade

controller option card. They are operated in open-loop

mode and receive their speed reference from the master

adjustable frequency drive. Pumps connected to slave

adjustable frequency drives are referred to as variable-

speed pumps.

Pumps connected to line power through a contactor or

soft starter are referred to as xed-speed pumps.

Each pump, variable-speed or xed-speed, is controlled by

a relay in the master adjustable frequency drive.

The cascade controller options can control a mix of

variable-speed and xed-speed pumps.

Built-in

1 VSP + 2 FSP

parameter group 25-** Cascade Controller

MCO 101

1 VSP + 5 FSP

parameter group 25-** Cascade Controller

MCO 102

1 VSP + 8 FSP

parameter group 25-** Cascade Controller

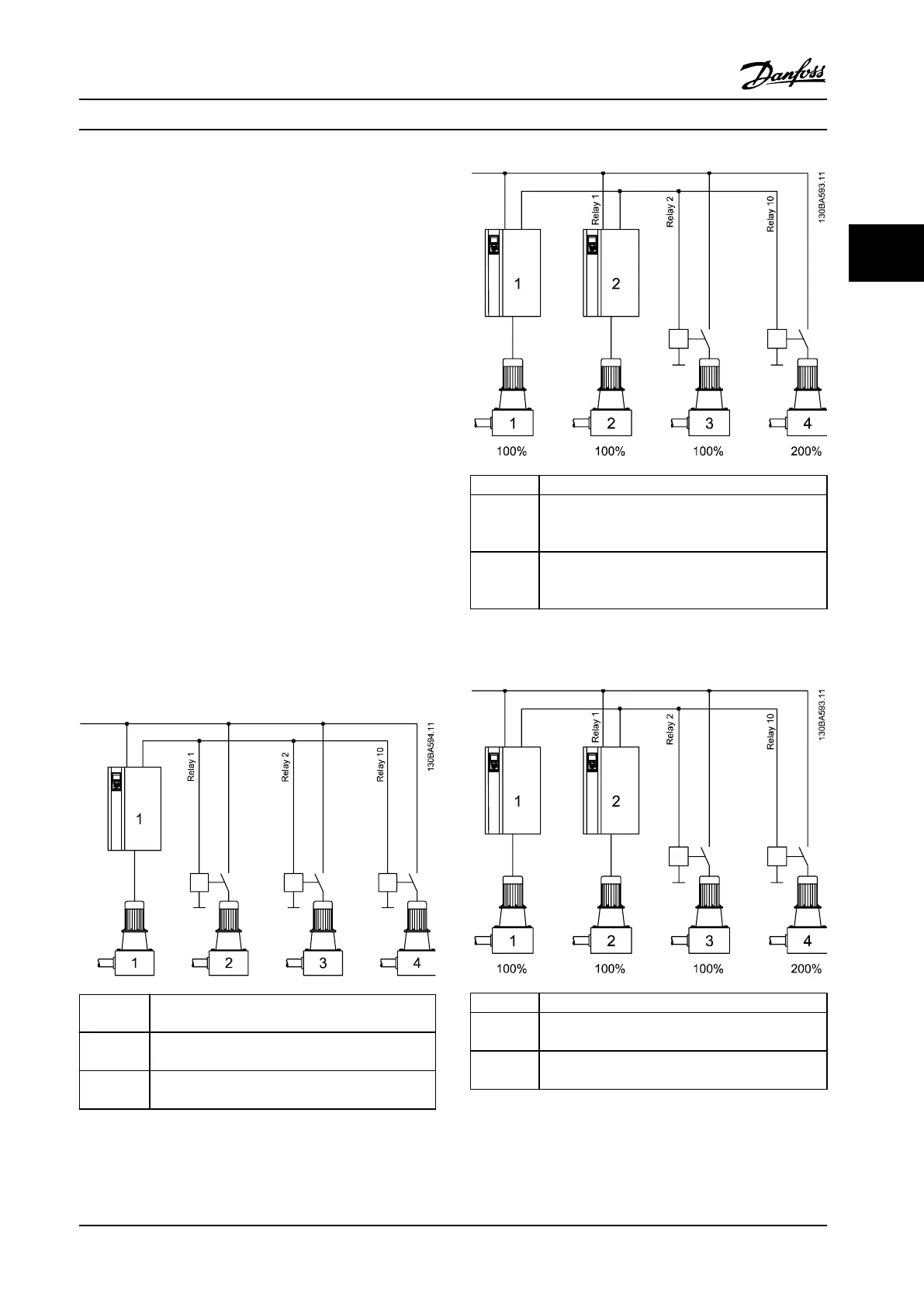

Figure 3.27 Application Overview

Built-in

-

MCO 101

1 to 6 VSP + 1 to 5 FSP

(maximum 6 pumps)

parameter group 27-** Cascade CTL Option

MCO 102

1 to 8 VSP + 1 to 7 FSP

(maximum 8 pumps)

parameter group 27-** Cascade CTL Option

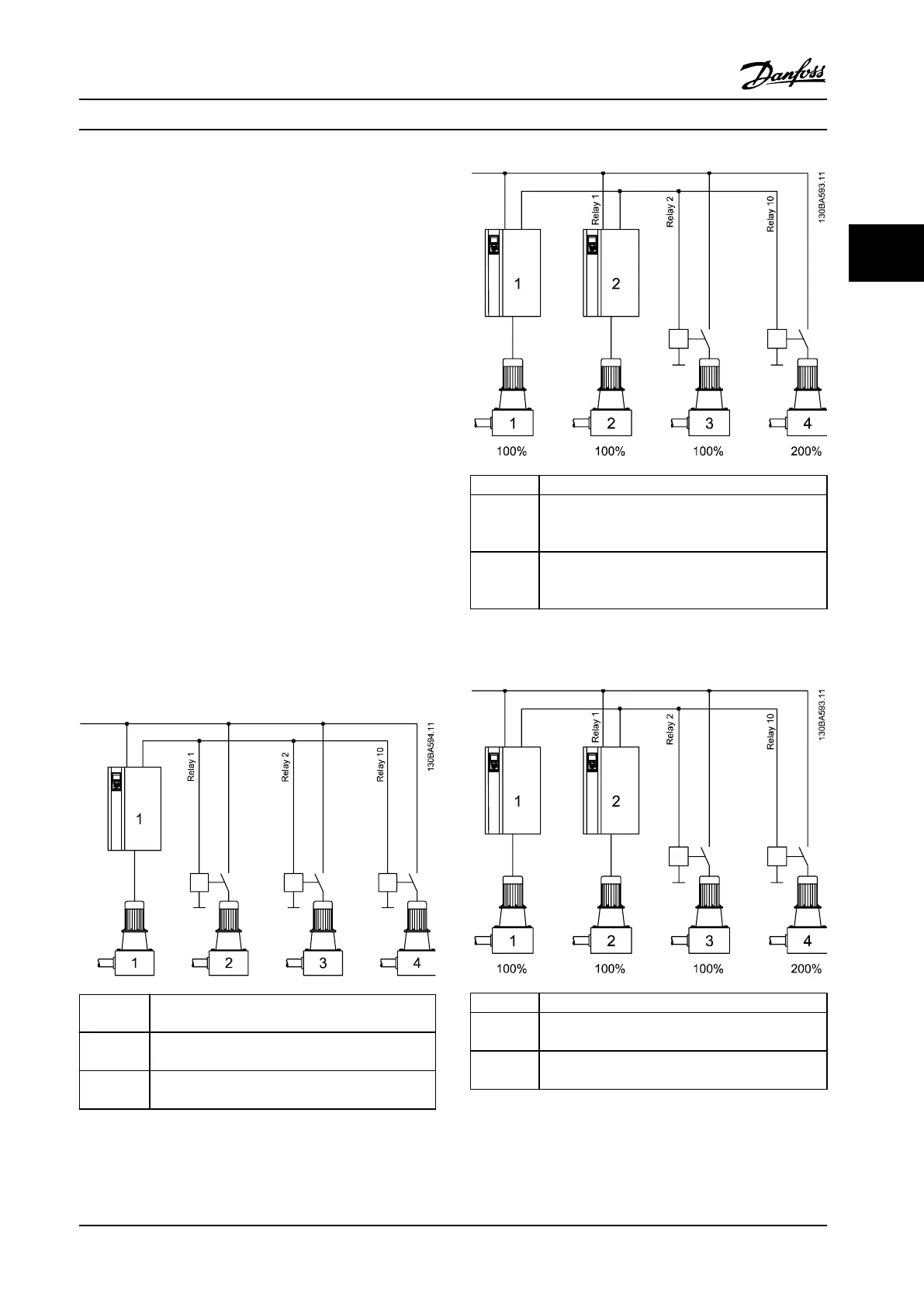

Figure 3.28 Application Overview

Built-in

-

MCO 101

6 VSP

parameter group 27-** Cascade CTL Option

MCO 102

8 VSP

parameter group 27-** Cascade CTL Option

Figure 3.29 Application Overview

System Integration Design Guide

MG20N622 Danfoss A/S © 09/2014 All rights reserved. 73

3 3

Loading...

Loading...