Pag 117 / 154

Manuale Lyra 600 sx elettr eng

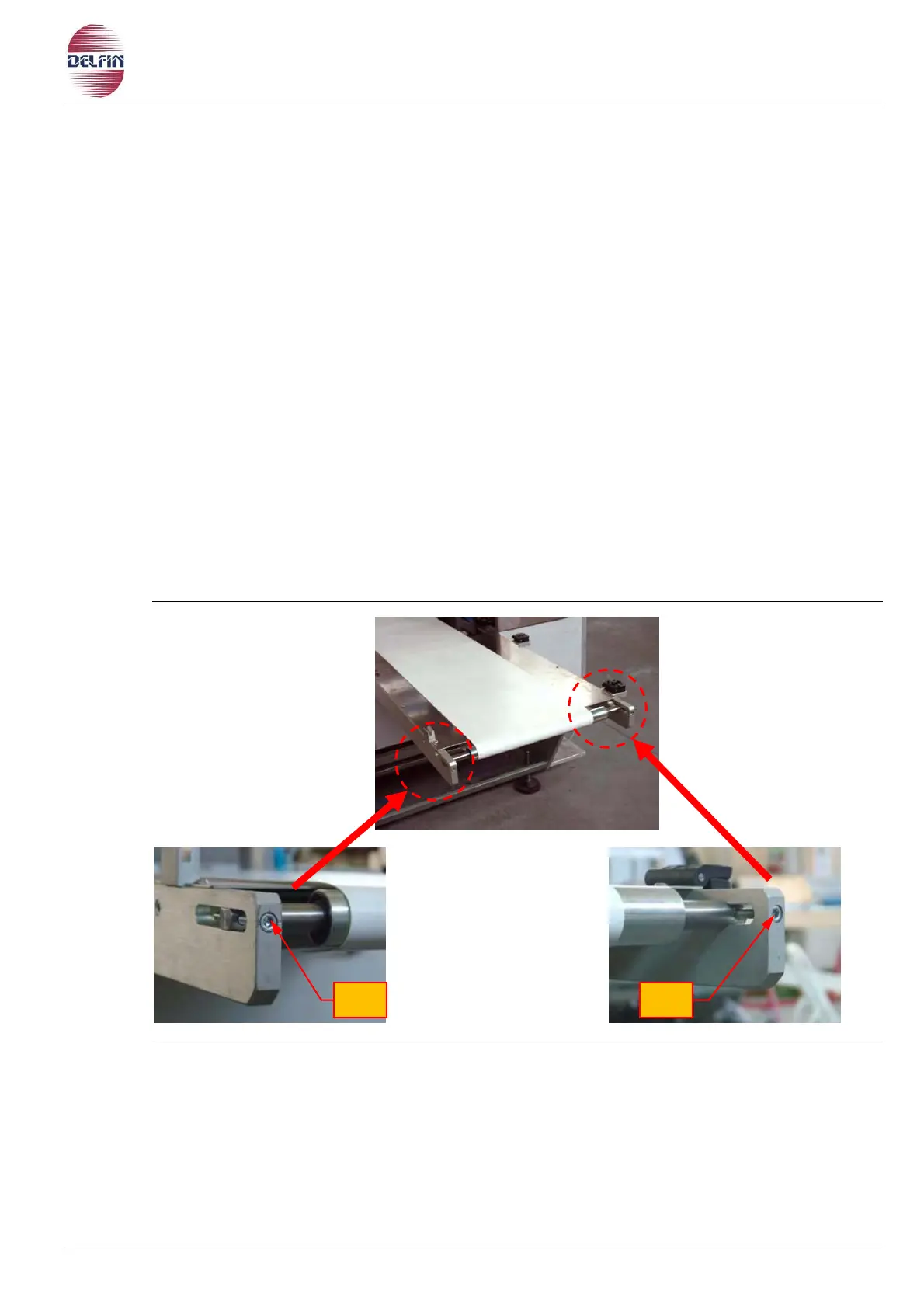

The discharge conveyor transports the product away from the sealing jaw towards the exit.

This machine type is equipped with a cantilevered outfeed conveyor with fixed pulling roller

and a product conveying top, horizontally adjustable to allow the sealing jaw to be set

closer or farther without altering the belt tension nor the driving mechanisms).

17.2 Maintenance

If the discharge conveyor is used correctly it will not require any particular maintenance,

the ball bearings are of the type "Life long lubrication".

The belt is to be cleaned every day in order to avoid the dirt from sticking and from going in

between the rollers.

The rollers are protected by a guard, the following operation is to be carried out when

inspecting them:

a) Disconnect the main electrical and pneumatic supply to the machine, by removing the

main plug to the machine.

b) Remove any empty bags and dirt from in between the rollers.

c) Switch on the main electrical supply.

Belt centering

Check that at the machine outfeed the rollers protrusion to left and to the right of the

conveyor is equal (if this condition is not fulfilled, follow the procedure described below).

Fig. 17.2 Outfeed conveyor font view

Loading...

Loading...