SV-EMS-220 Installation and Configuration

SkyView System Installation Guide - Revision K 7-29

as possible to the spot where you tap into the P-lead. This minimizes the length of cable

carrying high voltage spikes. Six-cylinder Lycoming engines sometimes need more inline

resistance to prevent false readings by the SV-EMS-220. If you supply your own resistors, they

need not be exactly 30 kΩ. Additionally, both 1/4W and 1/2W resistors are acceptable to use.

If, after setting the PULS/REV R and L values as described in the Engine

Information Section, you see higher than expected RPM or unstable values, you

may need to increase the series resistance to as high as 150 kΩ.

Trigger Coil (Rotax)

The Rotax 912 engines have a 5

th

trigger coil for the purposes of electrically monitoring rev

counts. This trigger coil outputs to a two-wire harness. Connect either of the two wires to

ground; connect the other to the standard RPM Left input on the SV-EMS-220. If you observe

erratic tachometer readings or momentary “spikes” in the display - particularly at higher RPM –

a 60K resistor installed inline (in series) in this wire may help.

Alternator Wire (Jabiru)

The most common tachometer pickoff location for Jabiru 2200 and 3300 engines is one of the

alternator wires. Connect one of the two white alternator wires through a 1 amp fuse to the

standard RPM Left input on the SV-EMS-220.

Digital Ignition and Other Pickoffs

The SV-EMS-220’s standard RPM inputs can read frequency-based RPM signals, provided the

peak voltage goes at least 5.1 volts above ground, and crosses back down below 2.0V relative to

ground. If the peak voltage exceeds 50 volts, use the included 30 kΩ resistors as described in

the P-lead pickoff (Lycoming and Continental) Section above. Like the other methods above,

you must know the number of pulses per revolution for your RPM transducer.

Low Voltage RPM Inputs

If you have an RPM source that outputs frequency-based RPM signals that are smaller than 10

volts above ground—such as Light Speed ignition outputs—use the low voltage RPM inputs.

These inputs require that the peak voltage goes at least 2.1 volts above ground, and crosses

back down below 0.8V relative to ground to be counted as a pulse.

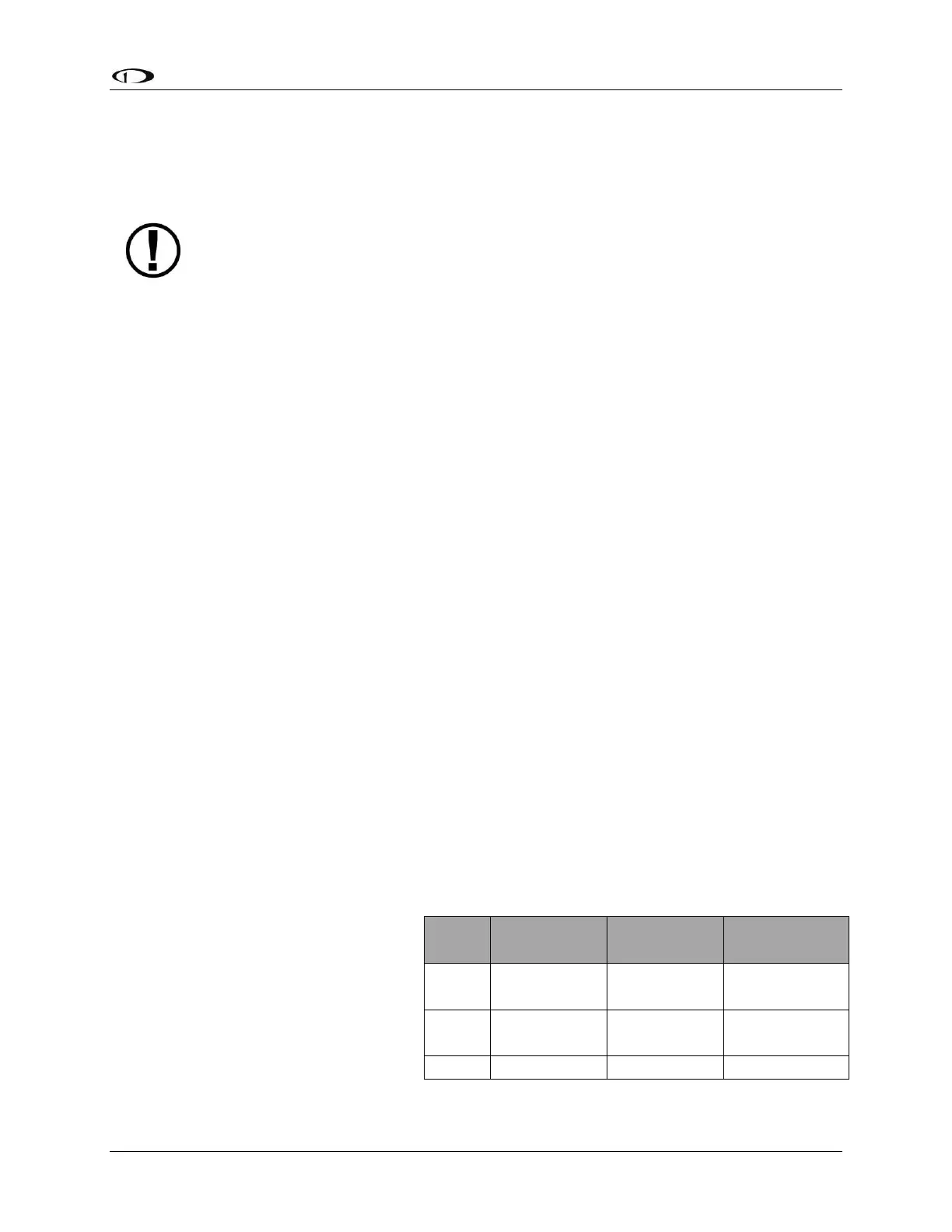

Manifold Pressure Sensor

The manifold pressure sensor is an

integral assembly consisting of three

pins, a rubber seal, and a connector

housing. Strip 3/16” insulation off the

ends of the three wires listed at right.

Slide the three rubber seals onto the

three wires and the pins onto the ends

of the wires. Crimp the 3 included pins

onto the ends of the wires, ensuring that

Table 33–Manifold Pressure Sensor Pins

Loading...

Loading...