Parameter List and Menu Structure of VS 300

134

Doku-Version 2.05 - Firmware 2.10 - 15. September 2017

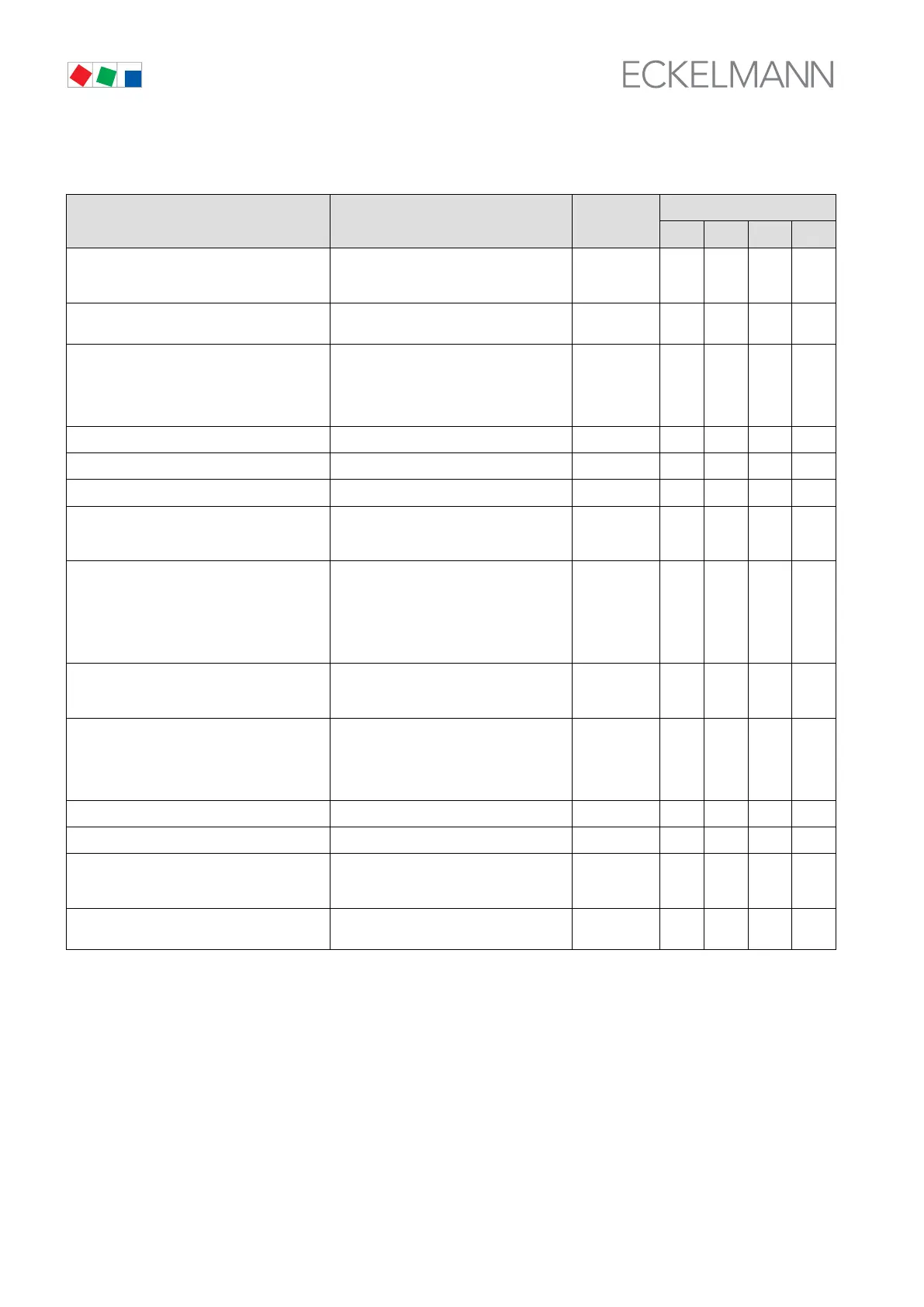

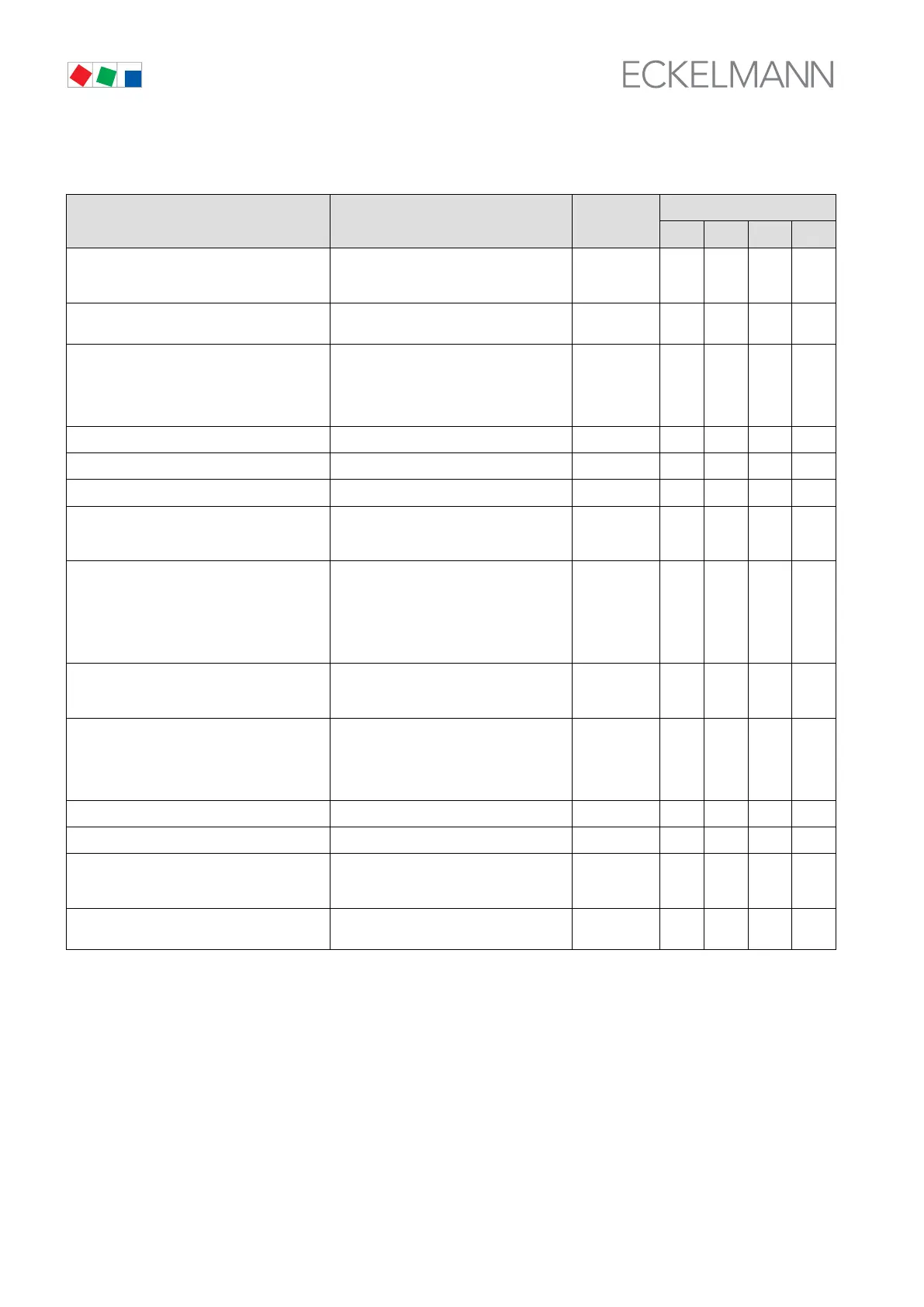

S Menu 3-4 Monitoring CL1/CL2

Monitoring POS: XXXXX Entry

Default

NT LT HP Dim.

tx-Hi Warn. CL1 XXX °C High Pressure CL1 alarm is generated if

temperature in CL1 rises above this level

1)

-30 - 55 0 -20 52 °C

tx-Hi Res. CL1 XXX °C Reset High Pressure CL1 alarm when

temperature drops below this level

1)

-35 - 48 -5 -2 45 °C

tx-Lo CL1 XXX °C Low Pressure CL1 alarm is generated if

temperature in CL1 rises above this level;

when activated, compressors of CL1 are

disabled at temperature below this level

-> only with LP control

-50 - 20 -25 -46 10 °C

Del.to-Hi CL1 XXX m High Pressure CL1 alarm delay

1)

0 - 60 10 10 10 min

Del.to-Lo CL1 XXX m Low Pressure CL1 alarm delay 0 - 60 10 10 10 min

Min Diff.toCL1 XXX K Minimum allowed difference to - tc

2)

5..15 --- --- - K

Starts/h CL1 XX Max. number of hourly compressor/fan

stage starts in CL1;

only with actuating mode by run time.

4 - 60 10 10 60 1/h

tx-Hi Warn. CL2 XXX °C High Pressure CL2 alarm is generated if

temperature in CL2 rises above this level;

when activated, compressors in CL1 can

be disabled - only with combination of LP

controller in CL1 and HP controller in

CL2.

-30 - 55 0 -20 52 °C

tx-Hi Res. CL2 XXX °C Reset High Pressure CL2 alarm when

temperature drops below this level;

reset compressor disabling CL1

-35 - 48 -5 -2 45 °C

tx-Lo CL2 XXX °C Low Pressure CL2 alarm is generated if

temperature in CL2 rises above this level;

when activated, compressors of CL2 are

disabled at temperature below this level

-> only with LP control.

-50 - 20 -25 -46 10 °C

Del.to-Hi CL2 XXX m High Pressure CL2 alarm delay

1)

0 - 60 10 10 10 min

Del.to-Lo CL2 XXX m Low Pressure CL2 alarm delay 0 - 60 10 10 10 min

Starts/h CL2 XX Max. number of hourly compressor/fan

stage starts in CL2;

only with actuating mode by run time.

4 - 60 10 10 60 1/h

Stg.tmax HP2. XX m No. of compressors running3) in CL at HP

fault in CL2.

0..

3)

- -

3)

-

1)

Only shown when control loop is configured as HP controller.

2)

Only show when Control Loop 1 is configured as LP controller and Control Loop 2 as HP controller.

3)

After changing compressor stages in CL1, this value is reset to the new default according to the table be-

low. Only shown when CL1 is configured as LP controller (NT or LT) and RK2 as HP controller:

Loading...

Loading...