Check of fuel system

The check must be executed both when the engine

disconnected and when it is running.

The check operation consists in examining the fuel pipelines

running from the tank to the pre-filter (if provided in the

specific equipment), to the filter, to the injection pump and to

the injectors.

Cooling system check

The check must be executed both when the engine

disconnected and when it is running.

Check the pipelines from the engine to the radiator, from the

expansion tank and vice-versa. Find out any blow-by, verify the

status of the pipes specially close to the holding strips.

Verify that the radiator is clean, the correct working of the fan

flywheels, the presence of any leakage from the connectors,

from the manifold and from the radiating unit.

Due to the high temperatures achieved by the

system, do not operate immediately after the engine’s

disconnection, but wait for the time deemed

necessary for the cooling.

Protect the eyes and the skin from any eventual high

pressure jet of cooling liquid.

Lubricating system check

The check must be executed both when the engine

disconnected and when it is running.

Verify the presence of any oil leakage or blow-by from the

head, from the engine pan of from the heat exchanger.

The engine oil is highly polluting and harmful.

In case of contact with the skin, rinse well with water

and detergent.

Adequately protect the skin and the eyes, operate in

full compliance with safety regulations.

Disposal must be carried out properly, and in full

compliance with the law and regulations in force.

Check of water presence within fuel filter or pre-filter

!

The components of the system can be damaged very

quickly in presence of water or impurity within the

fuel.

Timely proceed operating on the pre-filter (not

available on the engine block) to carry out the

drainage of the water within the feed circuit.

The density of the cooling liquid must be checked any how

every year before winter season and be replaced in any case

every two year.

In case of new filling, proceed bleeding system,

through the bleeds on the engine.

If bleeding of the system is not carried out, serious

inconvenience might be caused to the engine due to

the presence of air pockets in the engine’s head.

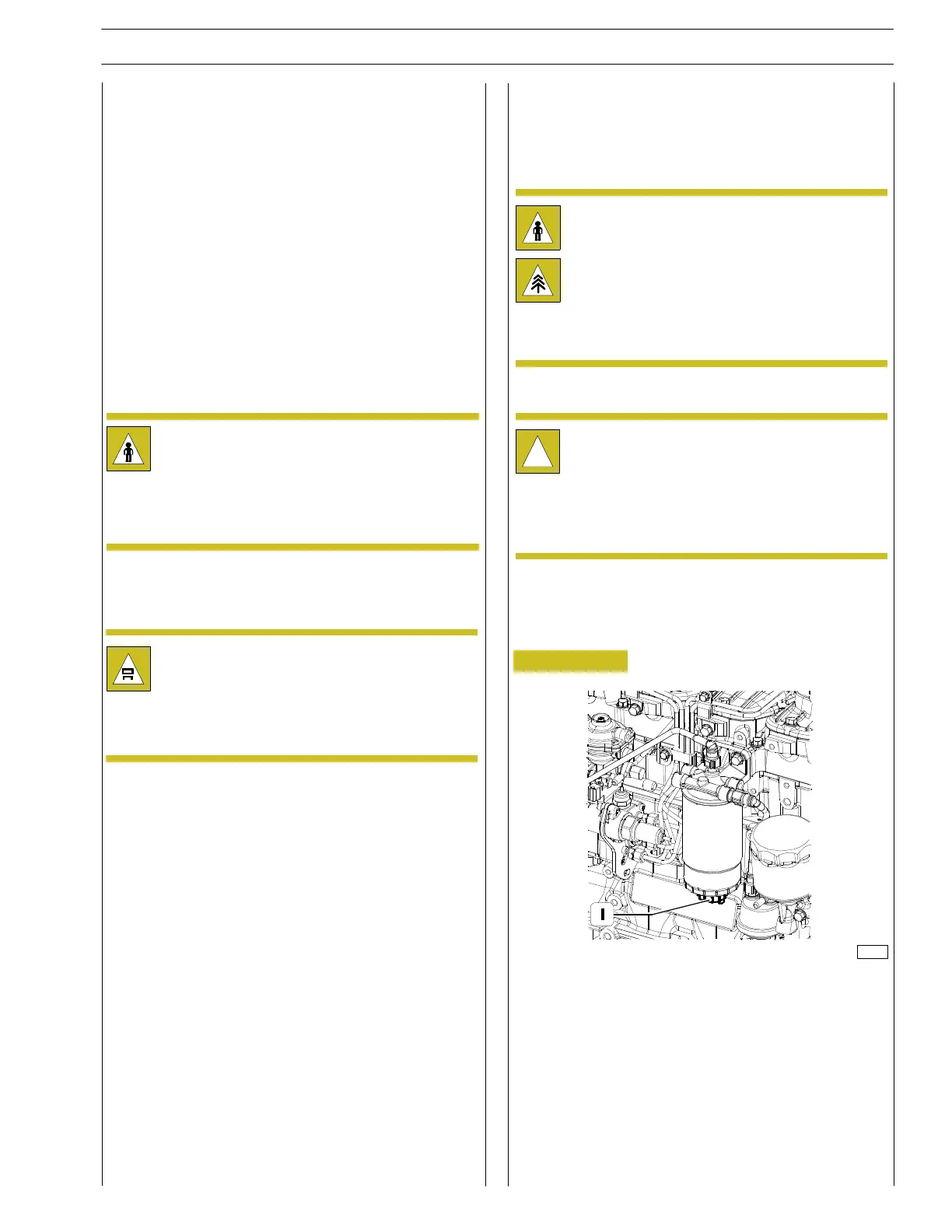

Fuel filter is equipped with pump tap-valve (1) to drain the

water eventually mixed with fuel.

Place a container underneath the filter and slightly loosen the

screw. Drain the water eventually contained in the filter’s

bottom.

Lock the tap (1) ( max 0.5 Nm locking couple) as soon as fuel

starts bleeding.

Figure 107

127699

SECTION 3 - INDUSTRIAL APPLICATION

63

F32 SERIES

Print P2D32F005 E Base - April 2009

Loading...

Loading...