64

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Base - April 2009 Print P2D32F005 E

Starting and

crankshaft

rotation

Balance

valves of

cylinder no.

Adjust

clearance of

intake and

exhaust valves of

cylinder no.

From 0.07 to 0.07 1 1

180 3 3

180 4 4

180 2 2

Revi - January 2010

On TIER 3 engines with internal EGR (F5CE9454, F5CE9484)

it is not possible to use the valve clearance adjustment

procedure in which all the valve clearances can be checked

using just 2 different crankshaft positions.

Check and setting of tappet clearance

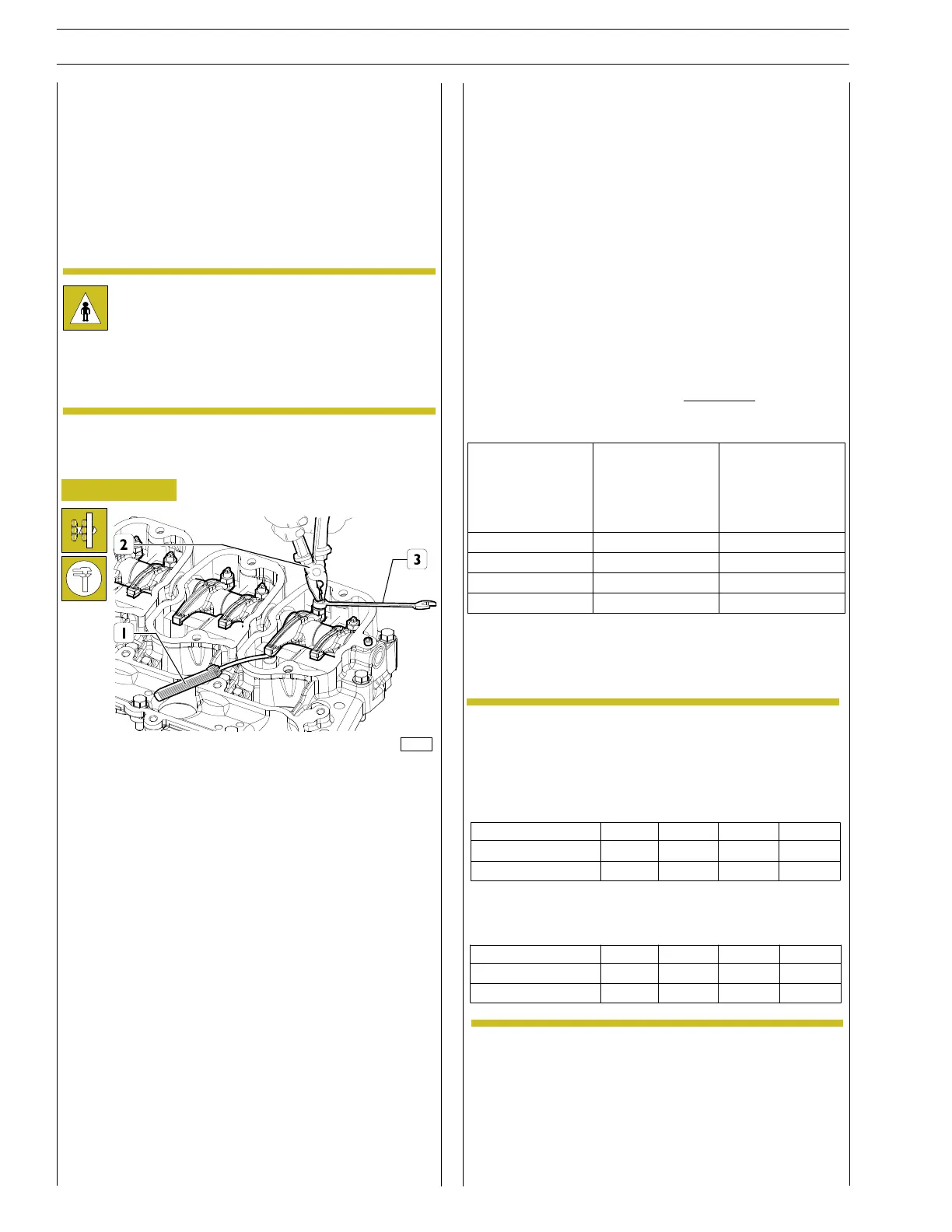

Figure 108

128138

Each cylinder must be checked by taking it to the T.D.C. (top

dead centre) at the end of compression and adjusting the

clearance of both valves on the cylinder in question.

Position the crankshaft at TDC of cylinder 1(see figures 5 and

6).

Rotate crankshaft as required (see table) and check that intake

and exhaust valves are both closed and not in a balanced

position.

For cylinder 4 it is possible to check the correct position of the

crankshaft with tool 99360612.

Adjust the clearance between the rockers and valves using a

pair of pliers (2), a wrench (3) and a feeler gauge (1).

Clearance shall be as follows:

- intake valves 0.5 ± 0.1 mm

- exhaust valves 0.50 ± 0.1 mm.

FIRINGSEQUENCE1-3-4-

2

In order carry out a quicker adjustment of the

working slack between rocker arms and valves,

proceed as following:

Rotate the engine drive shaft, balance the valves of

cylinder 1 and adjust the valves identified by star

symbol, as indicated in the following table:

Rotate the engine drive shaft., balance the valves of

cylinder 4 and adjust the valves identified by star

symbol, as indicated in the following table:

Cylinder n

Suction

Exhaust

1

234

*

*

--

-

*

-*

Cylinder n

Suction

Exhaust

1

234

*

-

*-

-

-

*

*

For F5CE5454 engines

NOTE

Check of belt’s tear and wear status

Carefully verify the belt’s surface in order to detect any sign of

incision, crack, excessive wear in correspondence of toothing;

check end and surface grinding.

Danger: if the engine is switched off but is still hot,

unexpected motion of the belt may occur.

Wait for engine temperature cooling as a precaution

in order to avoid serious danger injury.

Loading...

Loading...