SECTION 3 - INDUSTRIAL APPLICATION

65

F32 SERIES

Print P2D32F005 E Base - April 2009

Oilmotor and filter replacement

Due to the several applications, the pan shape and the oil

quantity can change slightly. However, the following oper-

ations are valid for all applications.

We recommend to carry out the oil drainage when the motor

is hot.

- Place a proper container for the oil collecting under the

pan connected with the drain plug.

- Unscrew the plug and then take out the control dipsick

and the inserting plug to ease the downflow of the lubrica-

tion oil.

Warning: We recommend to wear proper protec-

tions because of high motor service temperature.

The motor oil reaches very high temperature: you

must always wear protection gloves.

The oil motor is very pollutant and harmful.

Incaseofcontactwiththeskin,washwithmuchwater

and detergent.

Protect properly skin and eyes: operate according to

safety rules.

Dispose of the residual properly following the rules.

- After the complete drainage, screw the plug and carry out

the clean oil filling.

!

Use only the recommended oil or oil having the re-

quested features for the corrrect motor functioning.

In case of topping up, don’t mix oils having different

features.

If you don’t comply with theses rules, the service war-

ranty is no more valid.

- Check the level through the dipsick until when the filling

is next to the maximum level notch indicated on the dip-

sick.

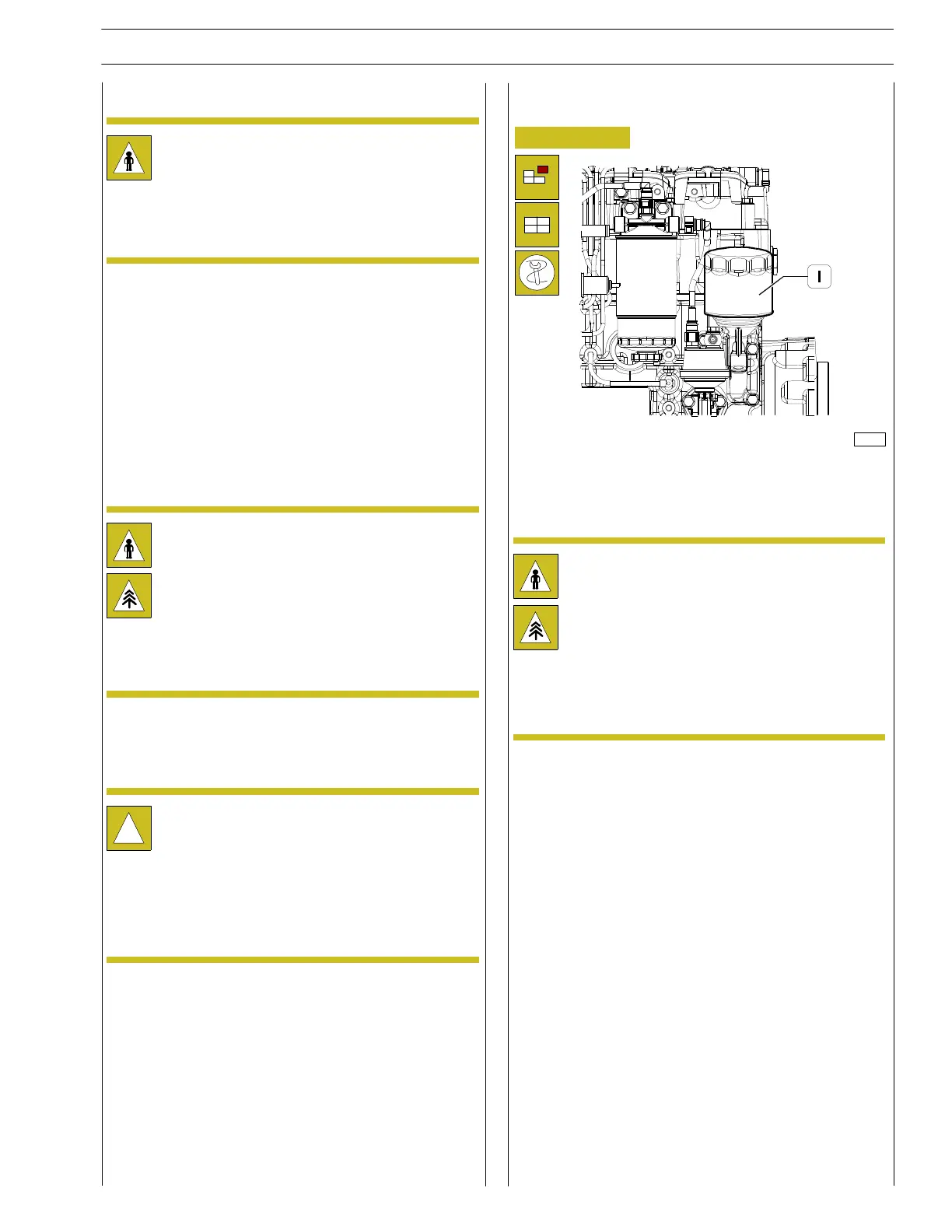

Figure 109

127700

Whereas you replace the lubrication oil, it is necessary to re-

place the filter.

- The filter is composed by a support and a filtering car-

tridge. For the cartridge replacement use the

9936076-tool.

Warning: the oil filter contains inside a quantity of oil

of about 1 kg.

Place properly a container for the liquid.

Warning: avoid the contact of skin with the motor oil:

in case of contact wash the skin with running water.

The motor oil is very pollutant: it must be disposed

of according to the rules.

- Replace the filtering cartidge (1) with a new one and

screw manually until when the gasket, previously

moistened by smearing with oil, is in contact with the sup-

port.

- Tigthen by means of the 99360076-tool and lock related

nuts at predefined torque 25 ± 2,5 Nm.

- Operate the motor for some minutes and check the level

through the dipsick again. If it is necessary, carry out a top-

ping up to compensate the quantity of oil used for the fill-

ing of the filtering cartridge.

Revi - 12.2012

Loading...

Loading...