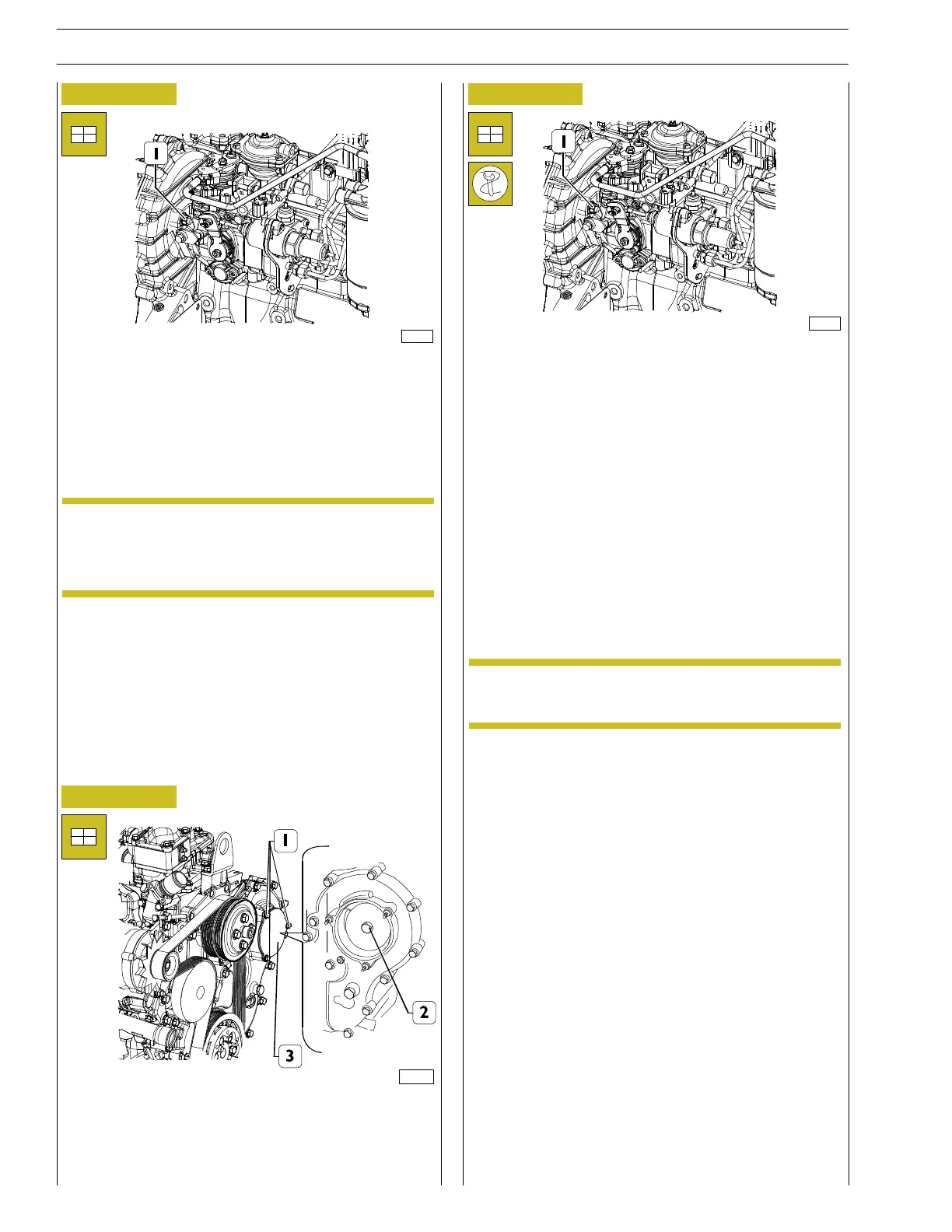

Figure 85

- Assemble the pump pre-set in its hou sing on the engine,

fitting the shaft into the gear port (not provided with

wrench).

- Tighten the fixing nuts (1) locking the pump flange in the

slot c ent re.

- On the timing side, throughout the specially appointed

port, fit the washer and screw up the fixing nut (2) to the

pump shaft. Lock the nut to the prescribed pair.

Figure 86

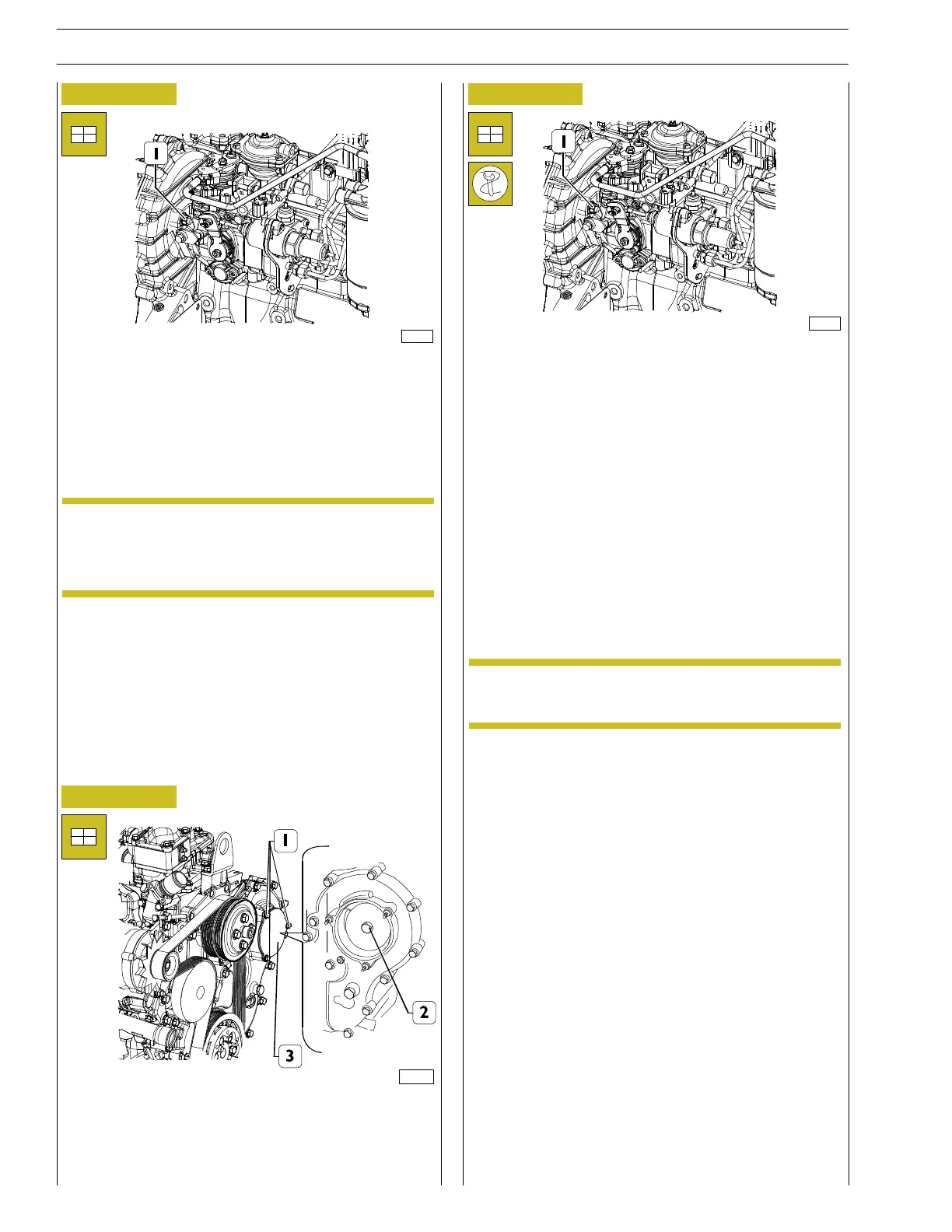

Figure 87

- Loosen screw (1) that prevents pump shaft rotation and

insert spacer (2). Tighten screw (1)so that it locks spacer

(2): in th is way the supply pump shaft will be able to

rotate freely.

- Assemble the cover (3, Figure 86) including gasket and

tighten the screws (1, Figure 86).

- Tighten the previously loosened plate screws.

- Connect all pipelines (from pumping elements to injectors,

bleeding recovery pipes from injectors to pump, LDA

pipeline and feed provided by priming pump).

- Connect electrical connections to electro-magnets on the

hydraulic head and on KSB.

The gasket removed during pump disassembly shall

not be utilised again .

Always use original spare parts.

If the pump has been removed with the engine

mounted, connect the accelerator cable, if present

in the application.

NOTE

NOTE

128132

124487

128132

32

SECTION 3 - INDUSTRIAL APPLICATION

F32 SERIES

Base - April 2009 Prin t P2D 32F005 E

Loading...

Loading...