112

If an increased welding circuit resistance is detected, e.g. after changing the welding torch,

this may mean that the following components are faulty:

- Torch hosepack

- Welding torch

- Grounding (earthing) connection to the workpiece

- Grounding cable

Welding circuit inductivity L [μH]

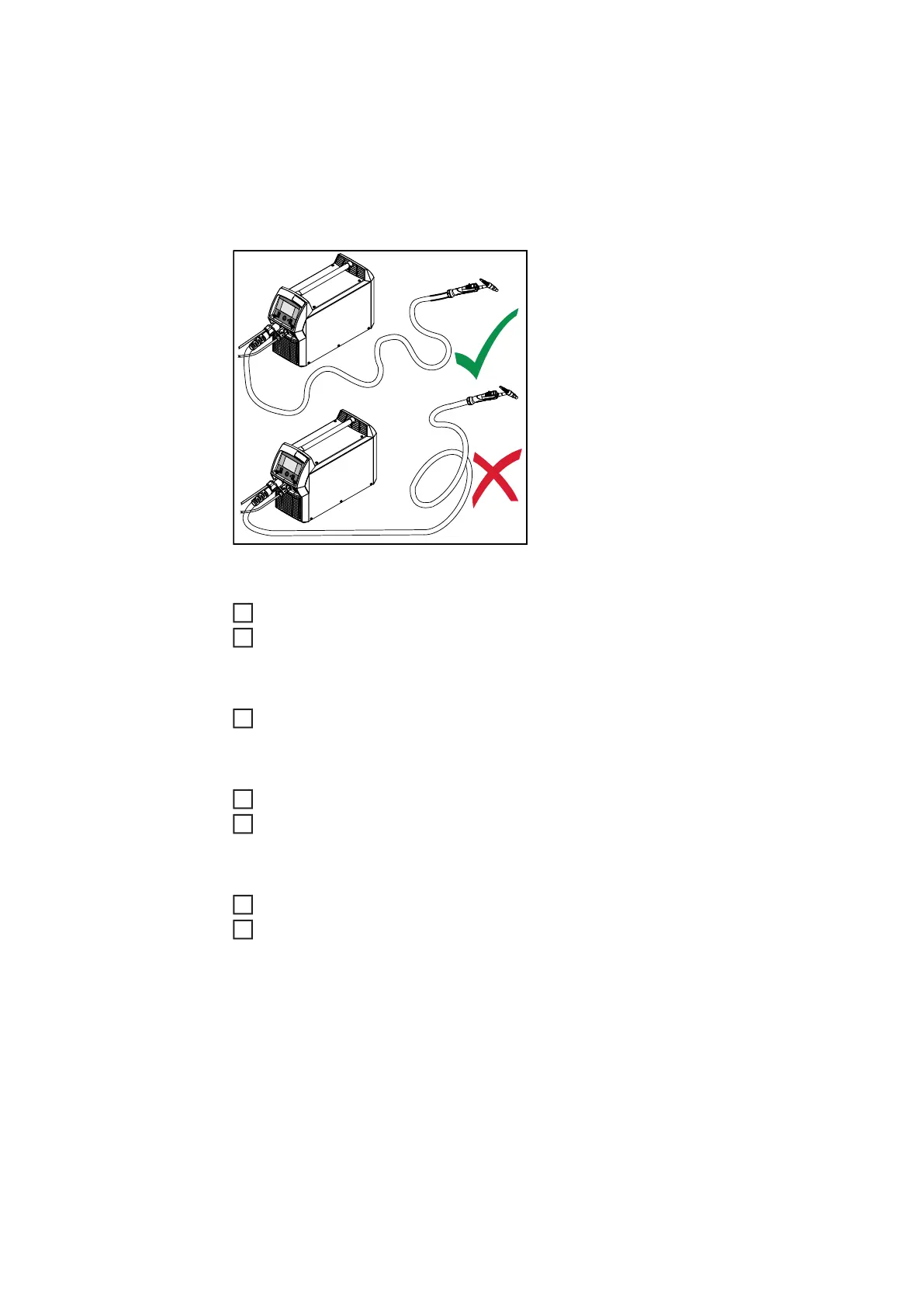

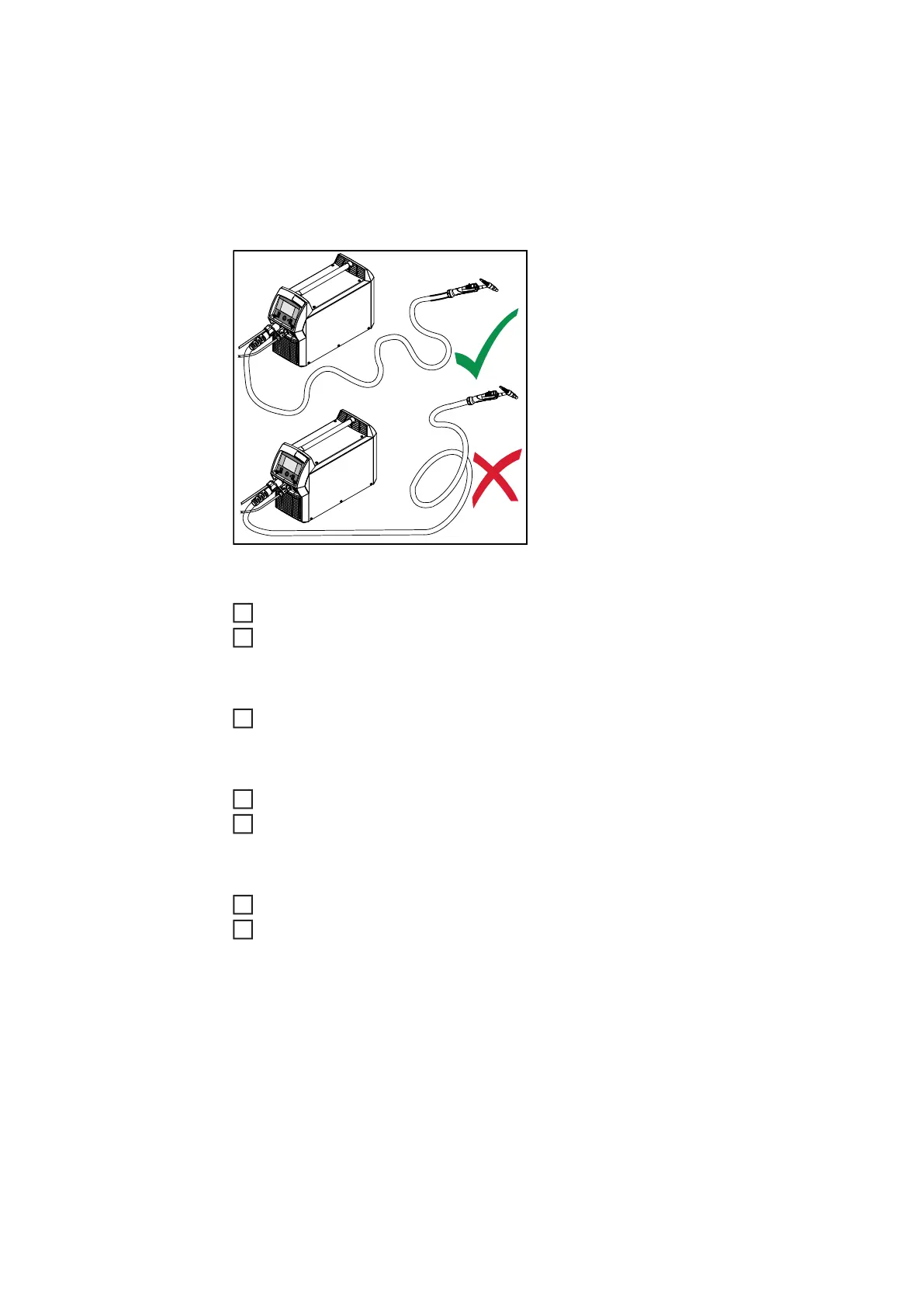

The way that the hosepack is arranged has

a very significant effect on the weld proper-

ties.

Particularly with pulsed-arc welding and AC

welding, a high welding circuit inductivity

may occur, depending on the length of the

hosepack and on the way that it is arran-

ged. The result is that the current rise is re-

stricted.

The weld results can be optimised by chan-

ging the arrangement of the torch hose-

pack.

The hosepack must be laid out as shown in

the illustration.

Performing R/L alignment

Defaults / System / Perform R/L alignment

Press the adjusting dial

The current values are displayed

Select More (turn adjusting dial and press)

The second R/L alignment screen is displayed.

Follow the instructions displayed on the screen

Select More (turn adjusting dial and press)

The third R/L alignment screen is displayed.

Follow the instructions displayed on the screen

Select "More" (turn and press adjusting dial)

The current values are calculated.

After R/L alignment has been completed, a confirmation and the current values are

displayed.

1

2

3

4

5

6

7

Loading...

Loading...