92

The MMA menu

Parameters in the

rod electrode

menu

Starting current time

HotStart

0.0 - 2.0 s

Factory setting: 0.5 s

To obtain optimum welding results, it will sometimes be necessary to adjust the HotStart

function.

Benefits:

- Improved ignition properties, even when using electrodes with poor ignition properties

- Better fusion of the base material in the start-up phase, meaning fewer cold-shut de-

fects

- Largely prevents slag inclusions

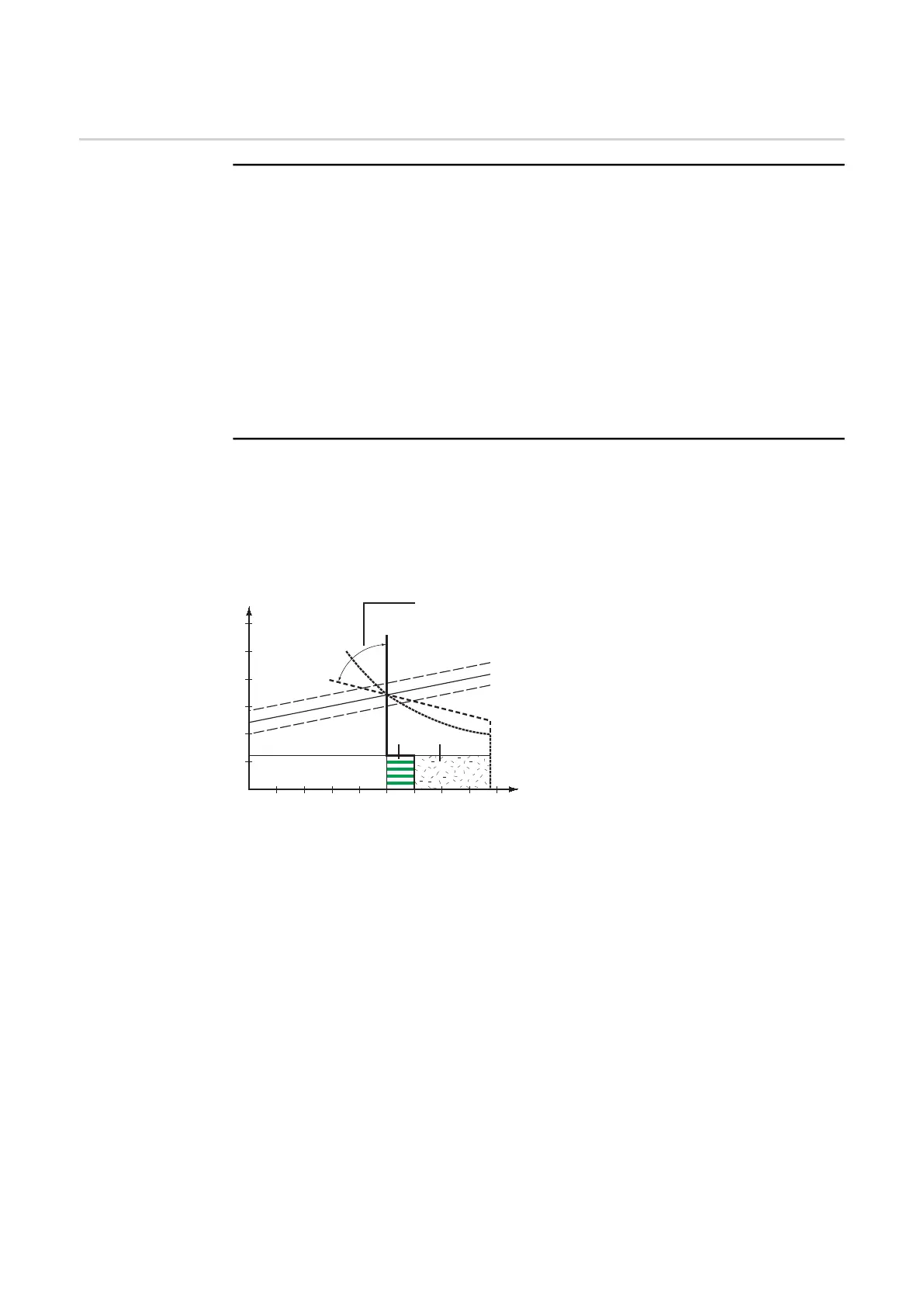

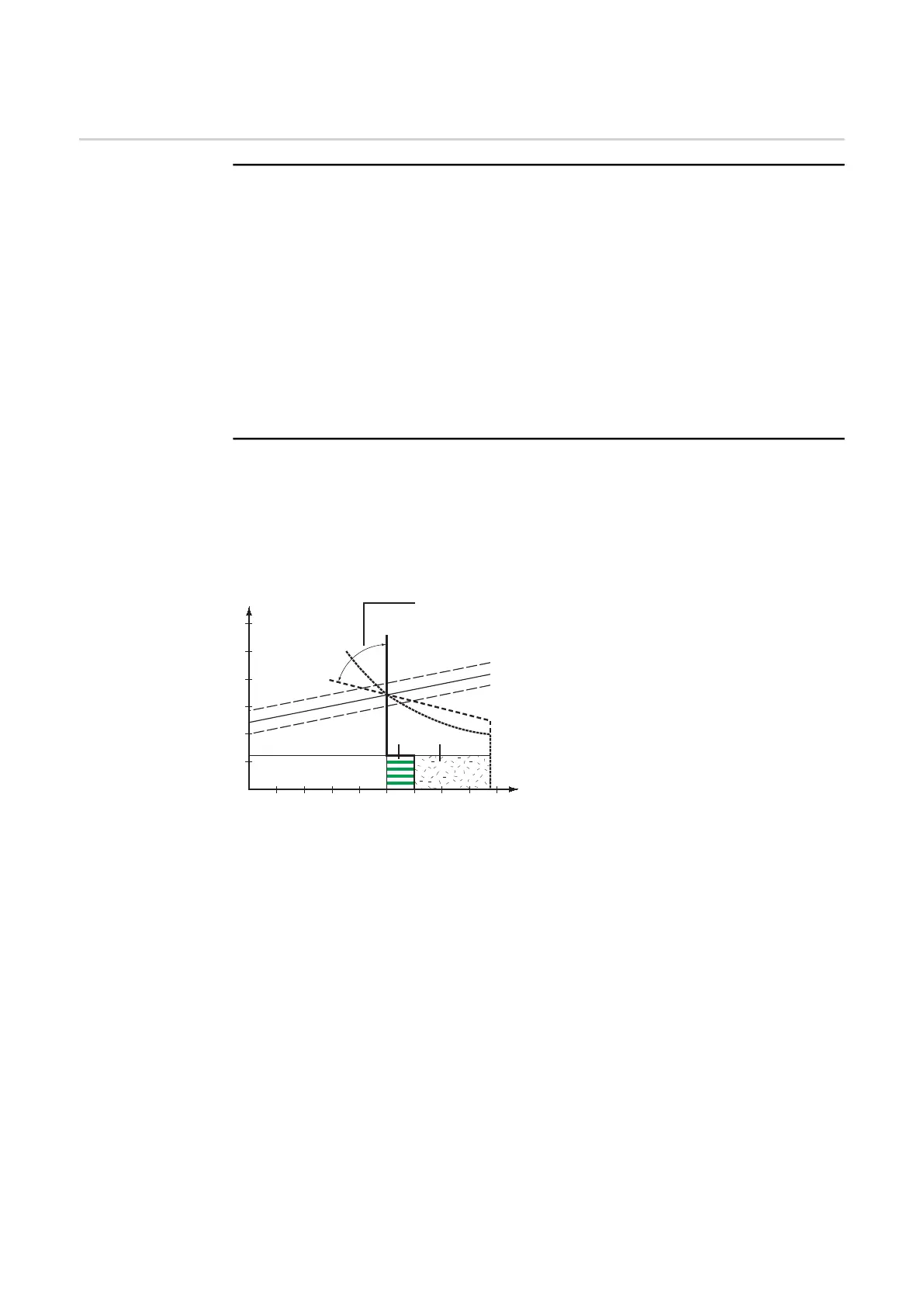

Char

To select characteristics

I-constant / 0.1 - 20.0 A/V / P-constant

Factory setting: I-constant

Adjustable characteristics

(1) Load line for rod electrode

(2) Load line for rod electrode where

arc length is increased

(3) Load line for rod electrode where

arc length is reduced

(4) Characteristic for parameter setting

I-constant (constant welding cur-

rent)

(5) Characteristic for parameter setting

0.1 - 20.0 (drooping characteristic

with adjustable slope)

(6) Characteristic for parameter setting

P-constant (constant welding pow-

er)

(7) Example of pre-set arc-force dynamic where characteristic (4) is selected

(8) Example of pre-set arc-force dynamic where characteristic (5) or (6) is selected

I-constant (constant welding current)

- If the I-constant characteristic is set, the welding current will be kept constant, irre-

spective of the welding voltage. This results in a vertical characteristic (4).

- The setting is particularly suitable for

rutile electrodes,

basic electrodes,

gouging (set the dynamic to 100 for gouging).

0.1 - 20.0 A/V (drooping characteristic with adjustable slope)

- Setting 0.1 - 20.0 is used to set a drooping characteristic (5). The setting range is from

0.1 A/V (very steep) to 20 A/V (very flat).

- Setting a flat characteristic (5) is only advisable for cellulose electrodes.

0040 200100 300 I (A)

U (V)

con - 20 A / V

(4)

(5)

(6)

(7) (8)

(1)

(2)

(3)

Loading...

Loading...