App1-14 Appendix 1 PLC2Way

Data Sampling in the PLC2 Memory

To perform data sampling in the PLC2 memory, the following settings are required.

• Temperature control network/PLC2Way table editing (Refer to page App1-10.)

• Buffering area setting

• Memory card setting (when [SRAM] or [CF Card] is selected for [Store Target] in the [Buffering

Area Setting] dialog)

• Trend sampling or data sampling setting (setting for displaying data stored in the specified buffer)

1. Buffering area setting

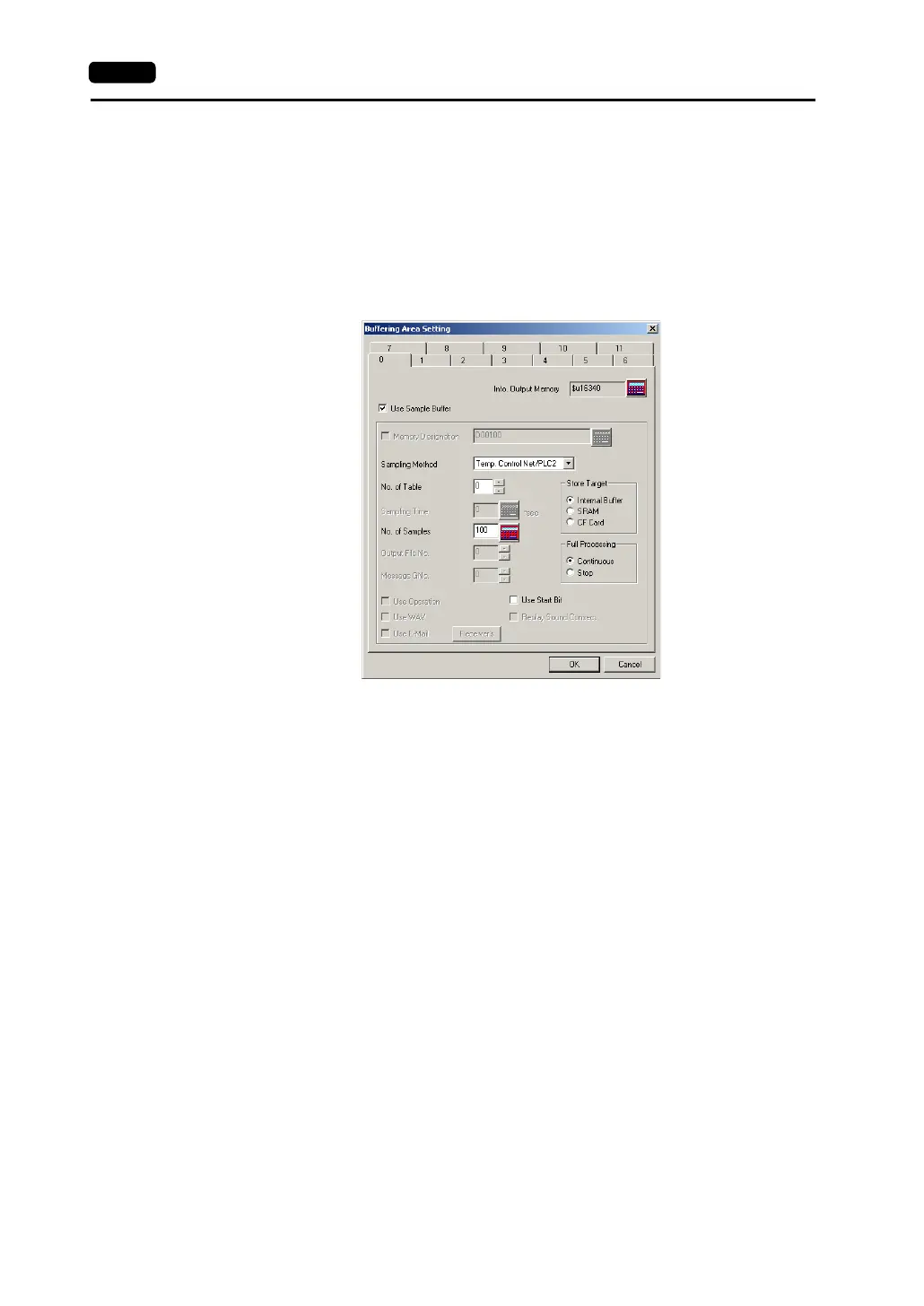

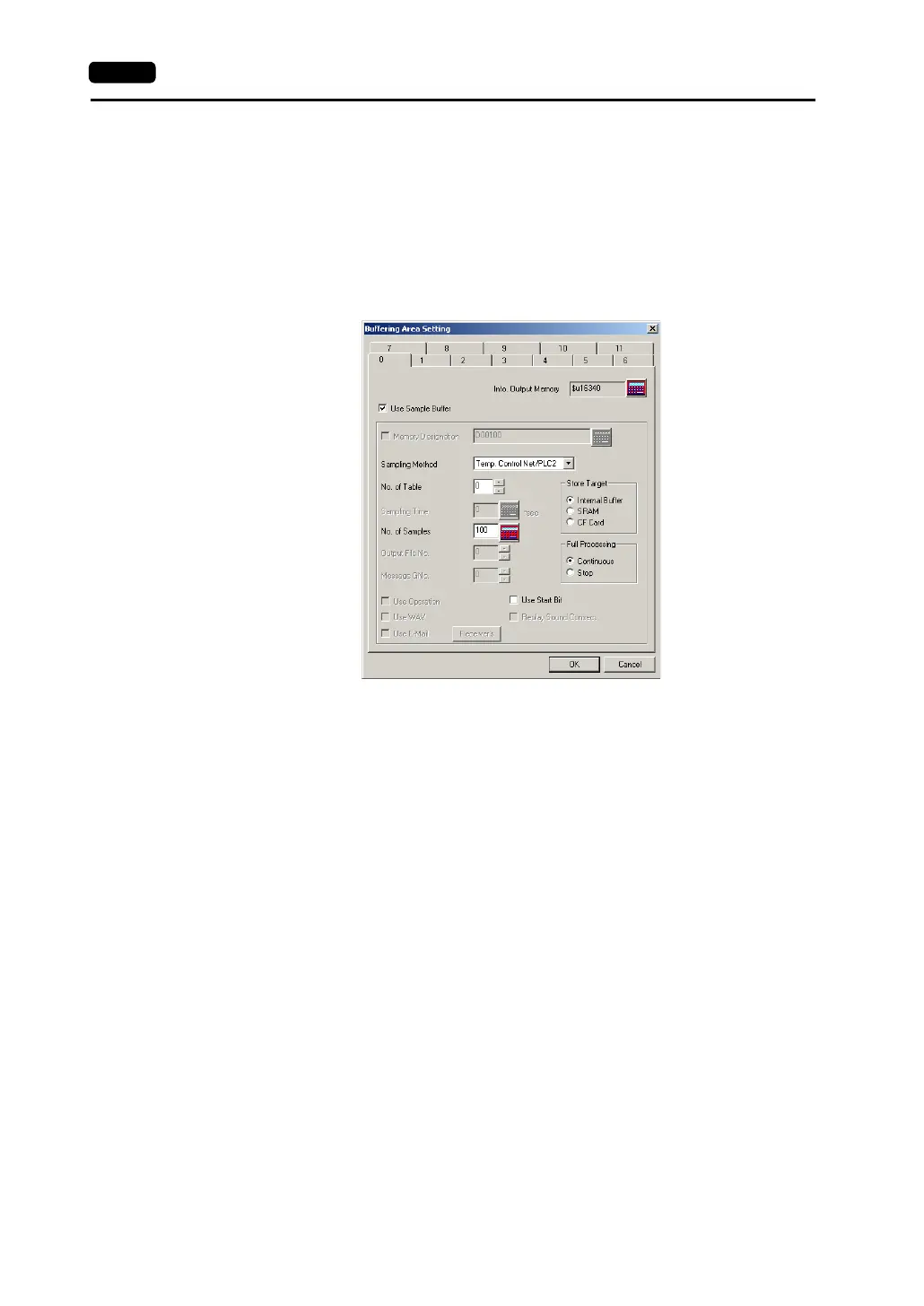

Click [System Setting] → [Buffering Area Setting]. The [Buffering Area Setting] dialog is opened.

[Sampling Method]

Temperature Control Net/PLC2

[No. of Table]

Select the temperature control network/PLC2Way table number for sampling.

[No. of Samples]

Specify the number of sampling times.

[Store Target] (Internal Buffer/SRAM/CF Card)

Choose the desired medium for storing sampling data.

- Internal Buffer: Stores data in the internal buffer of the V7 series. (RAM)

- SRAM: Stores data in the SRAM area.

(SRAM mounted on the unit, V7EM-S, REC-MCARD SRAM)

- CF Card: Stores data in the CF card.

[Full Processing] (Continuous/Stop)

Choose the desired processing when the target medium space has been used up.

- Continuous: When [No. of Samples] has been exceeded, data from the oldest is

discarded.

- Stop: When [No. of Samples] has been exceeded, sampling is stopped.

• Calculating the buffering area capacity

When [Internal Buffer] is selected for [Store Target] in the [Buffering Area Setting], the maximum

available capacity is 32k words.

When [Temp Control Net/PLC2] is selected for [Sampling Method], the required capacity can be

calculated as shown below.

1 sample = [Words*] + 2 words

Buffer size = [No. of Samples] × 1 sample

* [Words] here means the number of words in the memory addresses used in the temperature

control network/PLC2Way table that is set for [No. of Table].

Loading...

Loading...