106 Programming: Fundamentals, File Management

3.1 Fundamentals

Setting the datum

A production drawing identifies a certain form element of the

workpiece, usually a corner, as the absolute datum. When setting the

datum, you first align the workpiece along the machine axes, and then

move the tool in each axis to a defined position relative to the

workpiece. Set the display of the TNC either to zero or to a known

position value for each position. This establishes the reference system

for the workpiece, which will be used for the TNC display and your part

program.

If the production drawing is dimensioned in relative coordinates,

simply use the coordinate transformation cycles (see User’s Manual

for Cycle Programming, Cycles for Coordinate Transformation).

If the production drawing is not dimensioned for NC, set the datum at

a position or corner on the workpiece from which the dimensions of

the remaining workpiece positions can be most easily measured.

The fastest, easiest and most accurate way of setting the datum is by

using a touch probe from HEIDENHAIN. See "Datum setting with

touch probes" in the Touch Probe Cycles User’s Manual.

Example

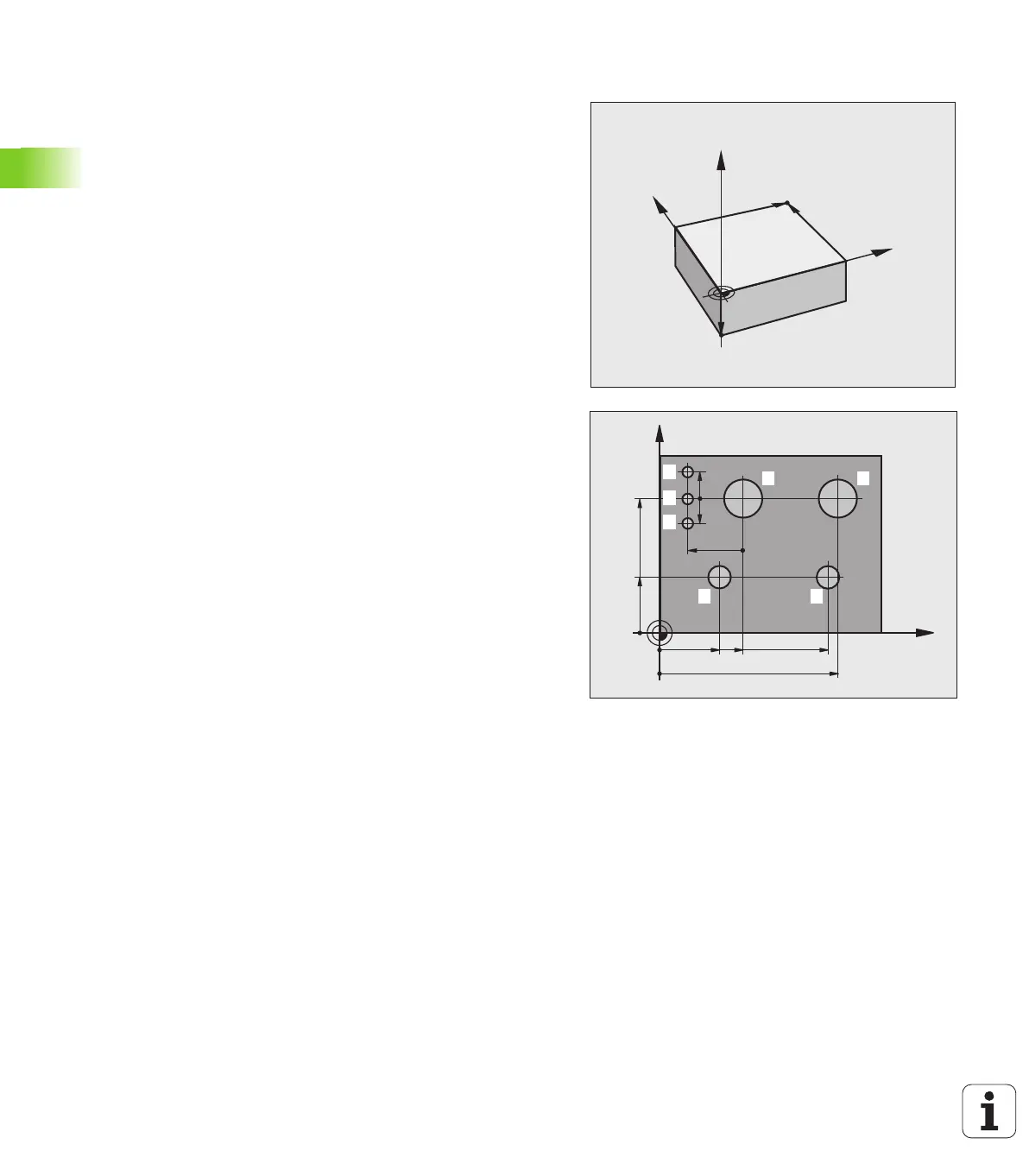

The workpiece drawing shows holes (1 to 4), whose dimensions are

shown with respect to an absolute datum with the coordinates X=0

Y=0. The coordinates of holes 5 to 7 refer to the relative datum with

the absolute coordinates X=450 Y=750. By using the DATUM SHIFT

cycle you can shift the datum temporarily to the position X=450,

Y=750 and program the holes (5 to 7) without further calculations.

X

Y

325

320

0

450 900

950

150

-150

750

0

300

±

0,1

21

3 4

7

6

5

Loading...

Loading...