HEIDENHAIN iTNC 530 215

5.3 Tool compensation

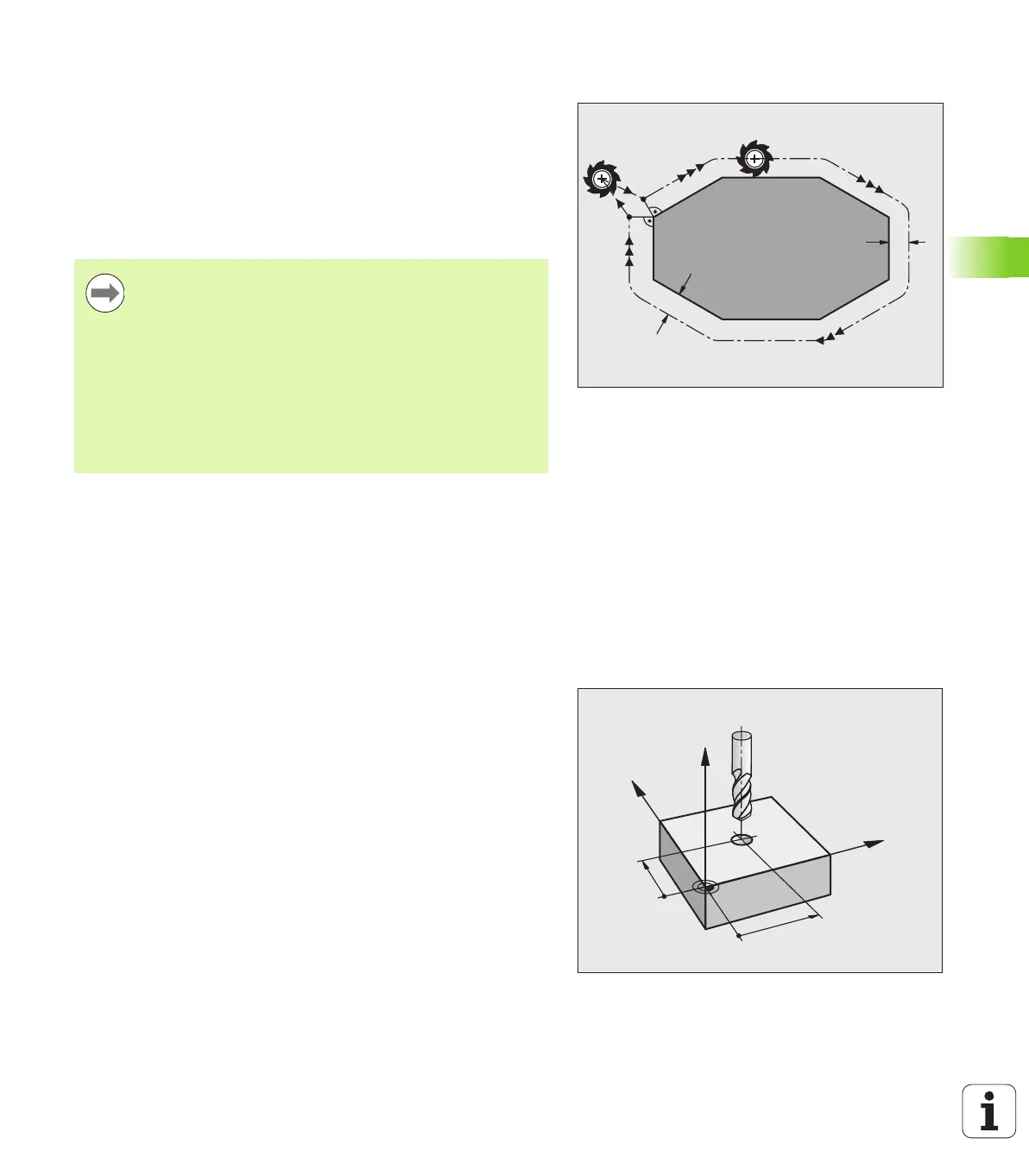

Tool radius compensation

The NC block for programming a tool movement contains:

RL or RR for radius compensation

R+ or R-, for radius compensation in single-axis movements

R0 if there is no radius compensation

Radius compensation becomes effective as soon as a tool is called

and is moved with a straight line block in the working plane with RL or

RR.

For radius compensation, the TNC takes the delta values from both the

TOOL CALL block and the tool table into account:

Compensation value = R + DR

TOOL CALL

+ DR

TAB

where

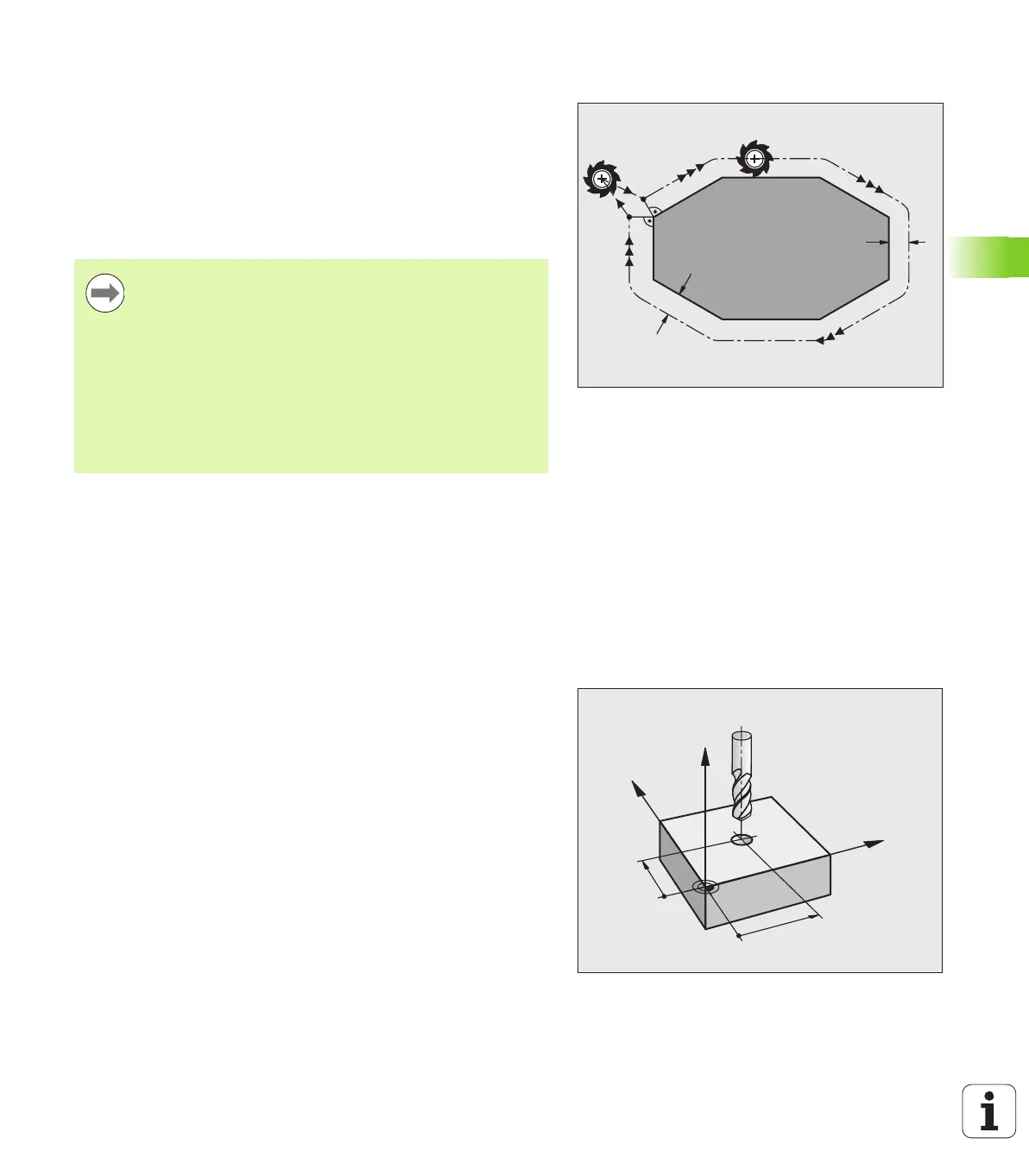

Contouring without radius compensation: R0

The tool center moves in the working plane along the programmed

path or to the programmed coordinates.

Applications: Drilling and boring, pre-positioning

The TNC automatically cancels radius compensation if

you:

program a straight line block with R0. If the straight-line

block contains only one coordinate in the tool-axis

direction, then the TNC cancels the radius

compensation but it does not necessarily move

correctly in the working plane.

depart the contour with the DEP function

program a PGM CALL

select a new program with PGM MGT

R: Tool radius R from the TOOL DEF block or tool table

DR

TOOL CALL

: Oversize for radius DR in the TOOL CALL block (not

taken into account by the position display)

DR

TAB:

Oversize for radius DR in the tool table

Loading...

Loading...