496 Programming: Execution of CAM Programs, Multi-axis Machining

12.3 The PLANE function: Tilting the working plane (software option 1)

Input parameters

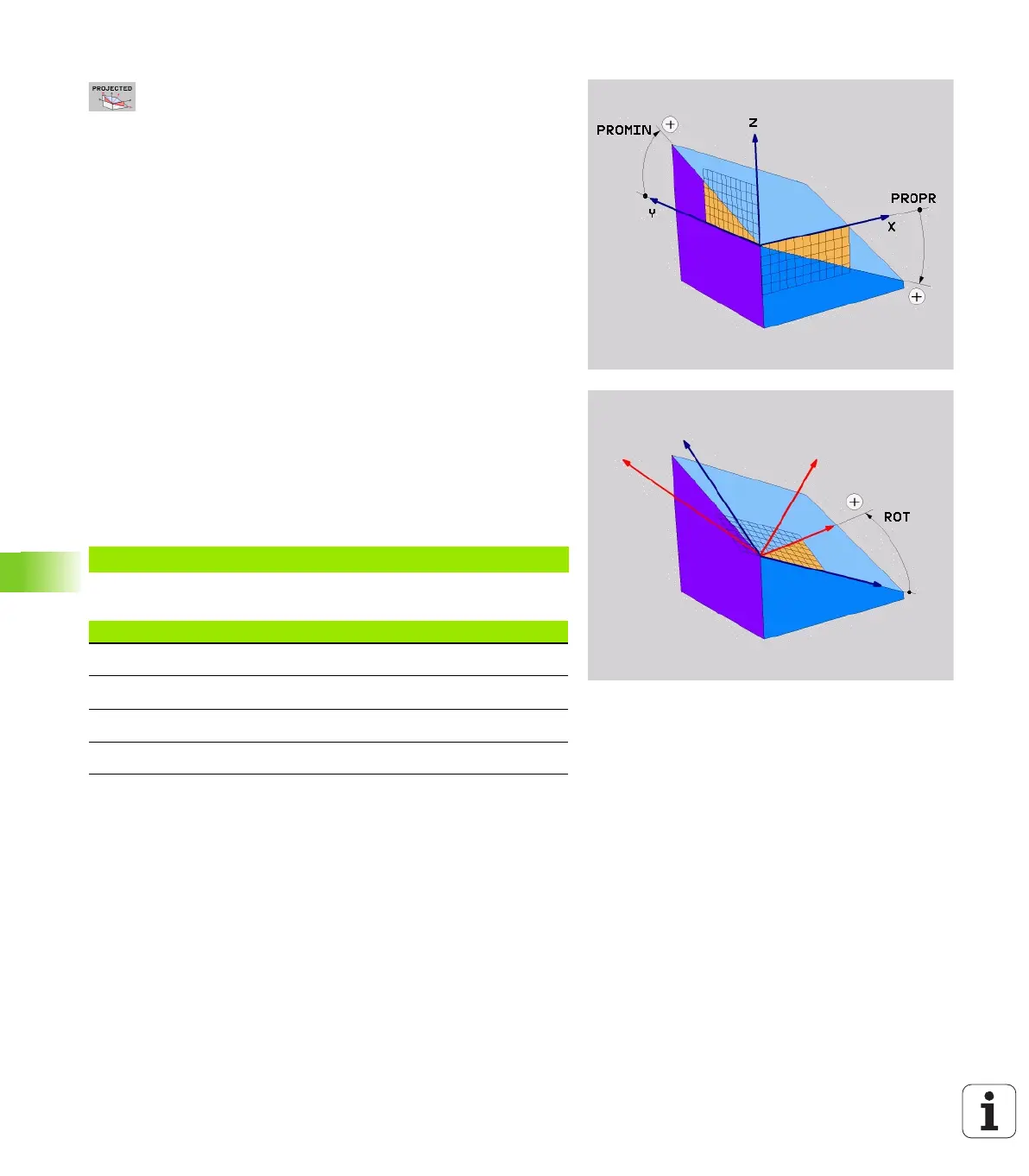

Proj. angle 1st coordinate plane?: Projected angle

of the tilted machining plane in the 1st coordinate

plane of the fixed machine coordinate system (Z/X for

tool axis Z, see figure at top right). Input range: from

-89.9999° to +89.9999°. The 0° axis is the principal

axis of the active working plane (X for tool axis Z. See

figure at top right for positive direction)

Proj. angle 2nd coordinate plane?: Projected angle

in the 2nd coordinate plane of the fixed machine

coordinate system (Y/Z for tool axis Z, see figure at

top right). Input range: from –89.9999° to +89.9999°.

The 0° axis is the minor axis of the active machining

plane (Y for tool axis Z)

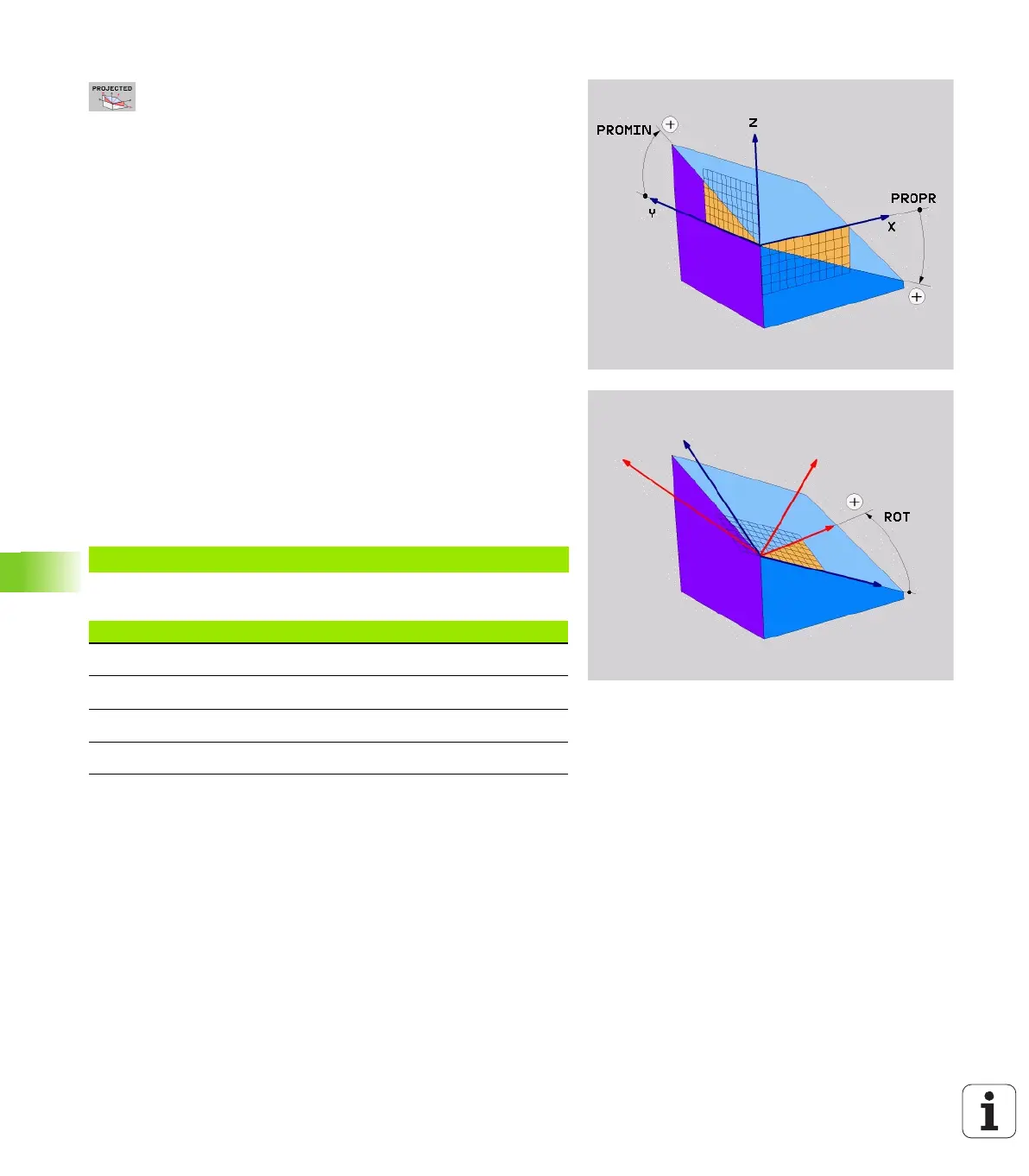

ROT angle of the tilted plane?: Rotation of the

tilted coordinate system around the tilted tool axis

(corresponds to a rotation with Cycle 10 ROTATION).

The rotation angle is used to simply specify the

direction of the principal axis of the working plane (X

for tool axis Z, Z for tool axis Y; see figure at bottom

right). Input range: from 0° to +360°.

Continue with the positioning properties (see

"Specifying the positioning behavior of the PLANE

function" on page 506)

NC block

Abbreviations used

5 PLANE PROJECTED PROPR+24 PROMIN+24 ROT+30 .....

Abbreviation Meaning

PROJECTED Projected

PROPR Principal plane

PROMIN Minor plane

ROT Rotation

Loading...

Loading...