5-15

5.9 Nozzle Orifice Cleaning

1) Detergent to use for an ultrasonic cleaning 2)Procedures of the cleaning

The ultrasonic cleaning with the

Weak-Alkali Detergent is effective for

the foreign objects of the nozzle orifice

which it is hard to remove with MEK or

makeup.

[About a Weak-Alkali Detergent]

① Characteristic of the detergent

Use household Weak-Alkali Detergent

Available on the market. (Detergent

to clean a ventilating fan, for example.)

Generally, Detergent on the market is

from 0.2 to 2 volume-% Weak-Alkali

solution.

② Labeling of articles on the market

(Example)

・ Liquid properties :

[Slightly-Alkaline,

Mildly-Alkaline or Alkalescent]

・ Ingredient :

[Surface Acting Agent]

・ Concentration :[0.2% - 1%]

・ pH :[In the range of pH8 – pH11]

③ Precautions for use

・ In case the liquid concentration is

0.2% - 1%, Use the detergent as it

is, UNDILUTED.

・ In case the liquid concentration is

1% or higher, dilute by approx.

0.2%-1% with water.

・ Follow the PRECAUTIONS FOR USE

and DISPOSAL of the article

purchased.

*1 Procedure to eject the makeup.

Execute the Ink stream alignment in the 2nd page of

Circulation control menu.

*2

TH-TYPE A is all right in substitution for pure water.

MEK is impossible of a substitute.

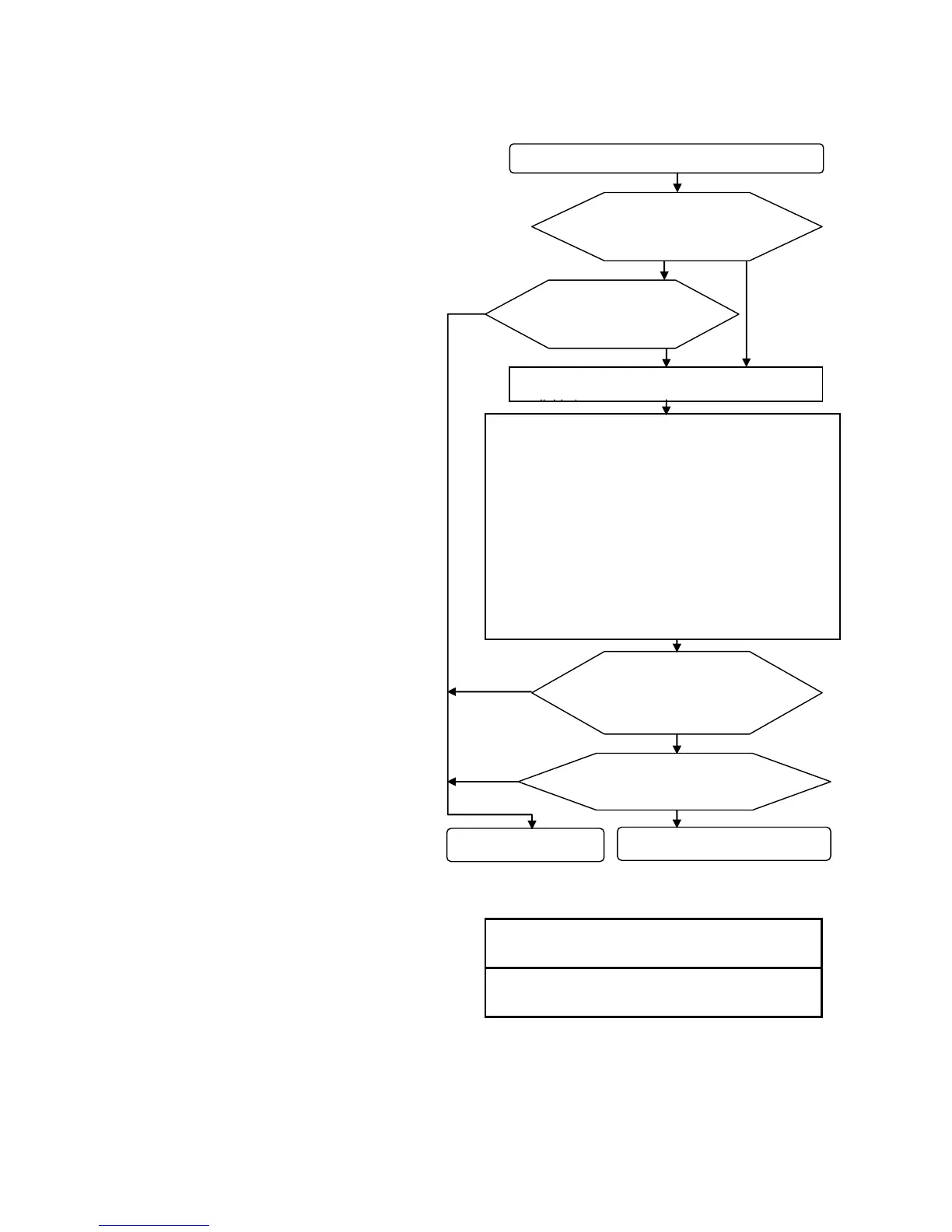

Nozzle Clogging or Ink Stream Bent occurred.

Remove the nozzle orifice plate. (Confirm if any

foreign object is attached by a microscope if

available.)

<Procedures of Ultrasonic Cleaning>

(1) Ultrasonic cleaning with MEK, or genuine Makeup to

remove ink component and other soluble substances

in solvent.

(2) Drying by air blow or leaving it for 3 to 5 minutes to

remove the solvent on the nozzle orifice surface.

(3) Ultrasonic cleaning with Weak-Alkali Detergent for

30 minutes to remove the foreign objects that cannot

be removed by MEK or Makeup. (See (1) above.)

(4) Ultrasonic cleaning with water (pure water) *2 for 3

minutes to rinse off Weak-Alkali surface active agent.

(5) Ultrasonic cleaning with ethanol for 3 minutes to

remove moisture by dissolving it in ethanol.

(6) Drying by air blow or leaving it for 3 to 5 minutes.

Set the orifice plate to the

nozzle, eject Makeup *1 and

confirm the ink stream position if

it is at the center of the gutter.

Change the orifice to

the spare part.

Ejecting ink, confirm the stream

position is almost the same as

that of stream alignment.

Repeat <Procedures of ultrasonic

cleaning> and confirm stream position.

(MAX 2 Times allowed.)

Eject the makeup *1 and confirm

the ink stream position if it is at

the center of the gutter.

Loading...

Loading...