2-24

2.6 Calibration of Viscometer

2.6.1 Calibration of viscometer

●The calibration of viscometer is to determine the “coefficient” inherent in the equipment.

●Calibrate the viscometer when installing equipment. Normally, calibrating it once is enough.

However, calibrate the viscometer again when changing the ink type, and also calibrate a new

viscometer after replacement.

●Be sure to calibrate the viscometer by using new ink.

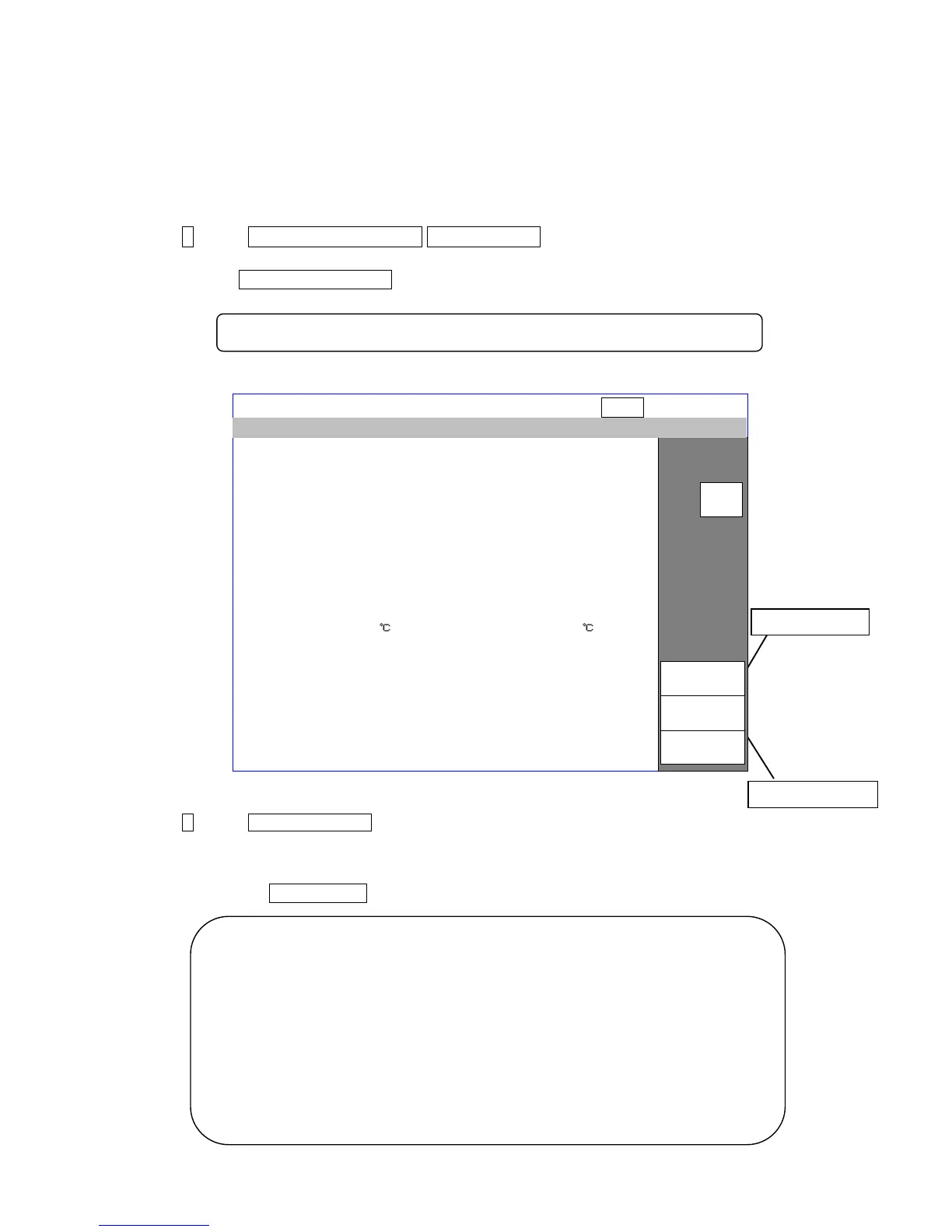

1 Press Viscometer calibration Start/Continue on the second page of the circulation

control menu of maintenance.

If Viscometer calibration is not displayed on the circulation control menu, set to the service

personnel maintenance mode on the login user selection screen.

The viscometer calibration screen is then displayed.

2 Press Start calibration.

During the viscometer calibration, the processing state “in progress” is displayed.

*) When the confirmation of the viscometer operation is performed without the calibration,

press Operation test.

For information on changing to the service personnel maintenance mode, refer

to “2.1 Setting of service personnel maintenance mode.”

[Note] Record the coefficient value or data backup is recommended.

The coefficient value is recorded in the memory on EZJ128 board.

So at the replacement of EZJ128, the calibration with new ink will be

required in case that the value is not recorded nor made a backup.

When the calibration of viscometer is performed continuously for a

number of times, ink temperature within the viscometer increases and

the accuracy of coefficient value is disturbed. Set a limit to the number

of times of performing viscometer calibration to not more than 3 times.

If in any case it needs to be performed more than 3 times leave for

about 30 minutes before performing again.

<the previous calibration>

Exec.time 2018/07/07 11:30

< the latest auto replenishment >

Exec.time 2018/07/07 12:45

Inside temperature XX ( )

Inside temperature XX ( )

Ink refilling log 2018/07/07 11:00

After “ink drainage” is completed, perform “ink refilling” of

a new ink first, then click [Start calibration].

Loading...

Loading...